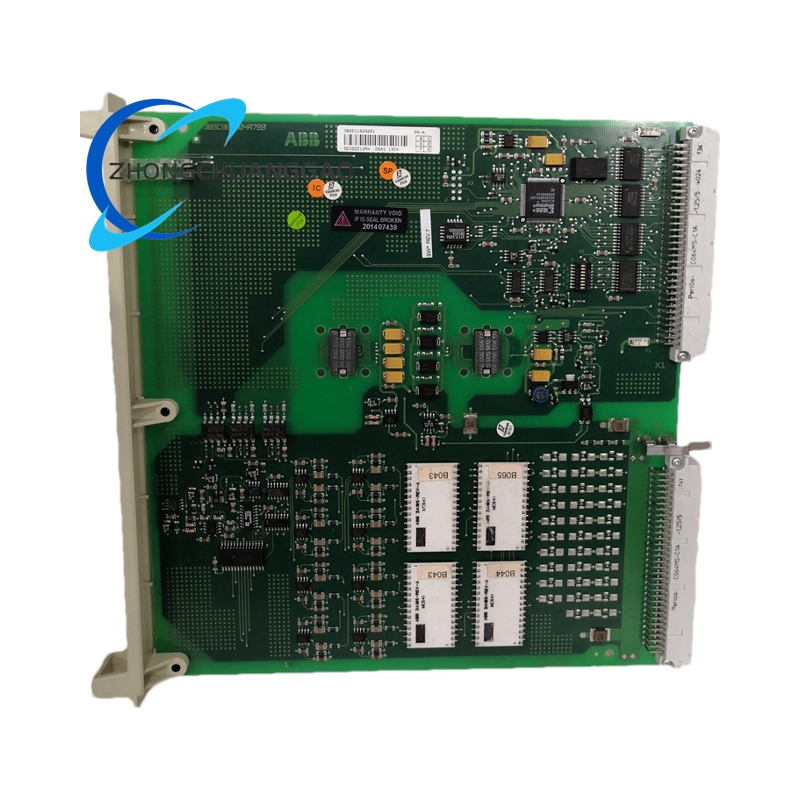

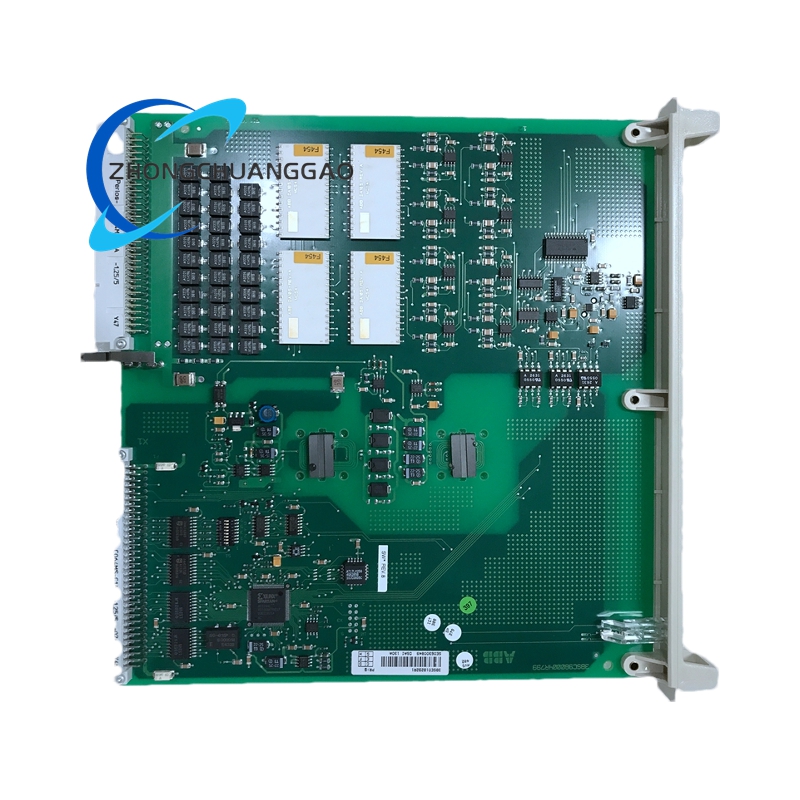

Product Short Description

Technical Specifications:

- Processor: High-speed ARM Cortex-based microcontroller for fast data processing.

- Memory: Sufficient RAM and Flash memory for storing control logic and runtime data.

- Communication Protocols:

- PROFIBUS DP (max data rate: 12 Mbps).

- MODBUS RTU/ASCII (max data rate: 115.2 kbps).

- Ethernet (IEEE 802.3).

- Optional support for DeviceNet, EtherCAT, and Modbus TCP/IP.

- Interfaces:

- Ethernet (RJ45).

- Serial ports (RS-232, RS-485).

- Industrial fieldbus connectors.

Description

- Power Supply: 24 V DC input with overvoltage, overcurrent, and short-circuit protection.

- Operating Temperature: -20°C to +60°C (industrial-grade).

- Storage Temperature: -40°C to +85°C.

- Dimensions: Compact form factor (e.g., 150 mm × 100 mm × 50 mm, specific to housing).

- Weight: Approximately 0.2–0.5 kg (module-dependent).

- Protection Rating: IP65 (dust and water-resistant).

Functional Characteristics:

- High-Performance Processing:

- Executes complex control algorithms and handles large I/O signal volumes with low latency.

- Supports multi-tasking for concurrent operations.

- Multi-Protocol Communication:

- Seamless integration with diverse devices (sensors, actuators, PLCs) via standardized protocols.

- Enables data sharing and system interoperability.

- Signal and Protocol Conversion:

- Converts ACS880 drive control signals and feedback signals to PROFIBUS DP protocol format.

- Converts PROFIBUS DP protocol control signals and feedback signals to ACS880 drive-recognizable formats.

- Digital Input/Output Module:

- Belongs to the S800 I/O series with 16 digital inputs/outputs.

- 24 V DC supply voltage, 4 ms input/output update time, and -40°C to +70°C operating temperature range.

- Modular Design:

- Easy installation, maintenance, and scalability through plug-and-play modules.

- Reduces downtime during upgrades or repairs.

- Fault Detection and Redundancy:

- Automatically switches to backup components in case of failure.

- Enhances system reliability and availability.

Application Scenarios:

- Distributed Control Systems (DCS):

- Coordinates communication between controllers, field devices, and HMI systems in process industries.

- SCADA Systems:

- Enables remote monitoring and control of distributed assets (e.g., pipelines, power grids).

- Process Automation:

- Regulates valves, pumps, and reactors in chemical, petrochemical, and pharmaceutical plants.

- Mechanical Engineering:

- Controls CNC machines, robotic arms, and conveyor systems with high precision.

- Energy Sector:

- Manages wind turbines, solar inverters, and hydroelectric generators.

- Manufacturing:

- Optimizes assembly lines, packaging systems, and quality inspection processes.

- Oil and Gas:

- Monitors drilling operations, pipeline pressure, and safety systems.

Key Advantages:

- Efficiency: Accelerates data exchange and decision-making in real-time environments.

- Flexibility: Adapts to varying system requirements through configurable protocols and I/O options.

- Durability: Withstands extreme temperatures, vibrations, and electromagnetic interference.

- Ease of Use: Simplifies programming, debugging, and system integration via user-friendly tools.

- Cost-Effectiveness: Reduces lifecycle costs through modular upgrades and predictive maintenance.

- Global Support: Backed by ABB’s worldwide service network and lifecycle management services.

Reviews

There are no reviews yet.