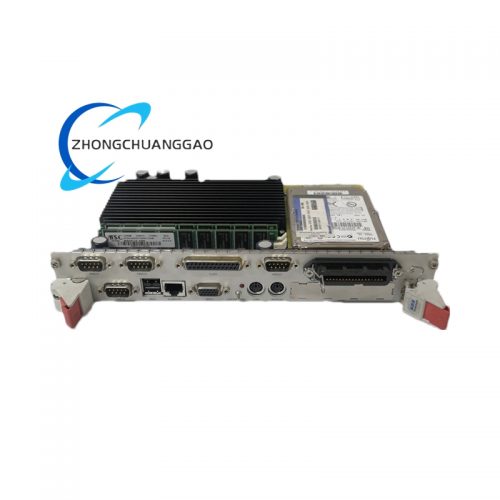

Product Short Description

Technical Specifications

- Communication Protocols:

- PROFIBUS DP/DP-V1 (up to 12 Mbit/s).

- MasterBus 300 (MB300) for integration with ABB System 800xA DCS.

- Ethernet support (10/100 Mbps) for network redundancy.

- Channels:

- Dual independent communication channels for redundancy.

- Connectors:

- PROFIBUS DP: 9-pin D-sub female connectors.

- Ethernet: RJ45 ports for network redundancy.

- Power Supply:

- Dual power redundancy: DC 9-36 V (typical 24 V DC).

- Power consumption: <5 W.

- Protection: DC 1500 V voltage isolation, reverse polarity protection.

- Physical Dimensions:

- Width: 132 mm, Height: 105 mm, Depth: 52 mm.

Description

- Weight: Approximately 800 g.

- Operating Temperature: -10°C to +70°C (wide-temperature version: -40°C to +85°C).

- Storage Temperature: -40°C to +85°C.

- Relative Humidity: ≤90% (non-condensing).

- Protection Class: IP30 (dust and water resistance).

- Mounting: 35 mm DIN rail installation.

- Certifications:

- EN55022:2010 (RE), EN61000-4-2:2001 (ESD), EN61000-4-3:2006 (RS).

Functional Features

- High Reliability:

- Industrial-grade components ensure stable operation in extreme conditions (vibration, electromagnetic interference).

- Redundancy Support:

- Dual-channel design with network redundancy and hot-swapping capability minimizes downtime.

- Dual-channel design with network redundancy and hot-swapping capability minimizes downtime.

- Multi-Protocol Compatibility:

- Supports PROFIBUS DP/DP-V1, MB300, and Ethernet protocols for seamless integration with ABB and third-party devices.

- Self-Diagnostics and Protection:

- Built-in fault detection for fiber link failures and power issues, with relay alarm outputs (DC 48 V/1 A).

- Easy Installation:

- Modular design with DIN rail mounting simplifies setup and maintenance.

- Scalability:

- Part of the ABB AC 800M I/O system, allowing flexible expansion of I/O capacity.

Application Scenarios

- Factory Automation:

- Connects remote I/O modules, sensors, and actuators in automotive, electronics, and food/beverage manufacturing for real-time control.

- Process Control:

- Integrates smart instruments, valve positioners, and frequency converters in chemical, petrochemical, and pharmaceutical plants for distributed process monitoring.

- Energy Management:

- Monitors and controls motor control centers (MCCs), low-voltage switchgear, and renewable energy systems (e.g., wind turbines, solar inverters) in power generation and distribution networks.

- Water Treatment:

- Links water quality analyzers, pump stations, and control equipment to build automated water treatment systems with real-time data acquisition.

- Material Handling:

- Controls conveyors, stackers, and warehouse management systems in logistics centers for efficient automation of material flow.

- Building Automation:

- Manages HVAC, lighting, and security systems in smart buildings for energy-efficient operation.

Key Advantages

- Enhanced System Availability:

- Redundant design ensures continuous operation even during communication failures.

- Scalability:

- Modular architecture allows easy expansion to meet evolving automation needs.

- Cost Efficiency:

- Reduces wiring complexity and maintenance costs through multi-protocol support and hot-swapping capability.

- Future-Proofing:

- Aligns with Industry 4.0 trends by enabling integration with smart devices and predictive maintenance systems.

Reviews

There are no reviews yet.