Product Short Description

- Core Measurement Parameters:

- Measurement Technology: Tunable Diode Laser Absorption Spectroscopy (TDLAS) or Infrared (IR) , depending on configuration.

- Gas Detection: O₂, CO, CO₂, CH₄, and other process gases (configurable per application) .

- Accuracy: ±2 ppm (for target gases like O₂/CO) .

- Response Time: <1 second .

- Measurement Range: Customizable (e.g., 0–100 ppm for trace gases; 0–100% for O₂) .

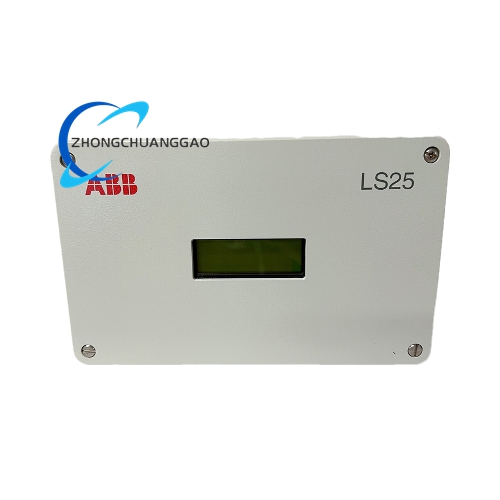

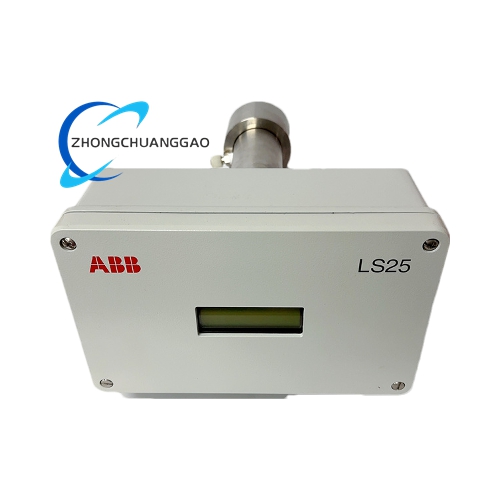

Description

- Physical & Environmental:

- Dimensions:

- Core Module: 20.4 × 12.6 × 7.5 mm (I/O board)

- System Enclosure: 380 × 180 × 110 mm (full analyzer) .

- Weight: 100 g (module) / 5 kg (full system) .

- Operating Temperature: -40°C to +85°C (core module) ; -20°C to +55°C (system) .

- Protection Rating: IP20 (module) / IP65/IP66 (system, harsh environments) .

- Housing Material: Polycarbonate (PC) .

- Dimensions:

- Electrical & Interfaces:

- Power Supply: 24 V DC ±10% or 100–240V AC .

- Output Signals: 4–20 mA DC (analog, ≤0.2% linearity error) ; Ethernet TCP/IP, RS-485, Modbus, PROFIBUS .

- Load Capacity: 0–600 Ω (for 4–20 mA) .

- Data Performance:

- Stability: ≤0.1% F.S./24h .

- Calibration: Automatic self-calibration .

Functional Features

- Advanced Sensing Technology:

- Utilizes TDLAS for high-selectivity gas detection, immune to cross-interference from other gases .

- Infrared Laser (in IR configurations) for broad-spectrum gas analysis .

- Modular & Scalable Design:

- Integrates with other Advance Optima series modules (e.g., sample conditioning, additional gas sensors) for multi-gas monitoring .

- Hot-swappable components for maintenance without process interruption .

- Robust Industrial Engineering:

- Conformal Coating protects electronics against humidity, chemicals, and particulates .

- Explosion-Proof Certification: ATEX/IECEx/CSA for hazardous areas (Zone 2) .

- Smart Connectivity & Control:

- Remote Operation: Fully controllable via Ethernet/OPC servers; supports cloud-based SCADA integration .

- Real-Time Diagnostics: Front-panel LEDs and event logging (>10,000 entries) for fault alerts .

Application Scenarios

| Industry | Use Cases | Key Measurement Parameters |

|---|---|---|

| Power Generation | Flue gas analysis (O₂, CO) for combustion optimization and emissions control | O₂: 0–25%; CO: 0–1,000 ppm |

| Oil & Gas | Pipeline leak detection (CH₄); refinery process gas monitoring | CH₄: 0–100% LEL; H₂S: 0–50 ppm |

| Chemical Plants | Reactor safety (toxic gas detection); batch process control | Cl₂, NH₃, or custom gas ranges |

| Environmental | Ambient air quality (CO₂, NOₓ); wastewater treatment | CO₂: 0–5,000 ppm; NOₓ: 0–500 ppm |

| Pharmaceuticals | Controlled atmosphere monitoring (sterilization, inerting) | O₂: 0–1% (trace); CO₂: 0–20% |

Compatibility & Integration

- Hardware Ecosystems:

- ABB Systems: Integrates with Advance Optima AO2000 series racks and modules .

- Third-Party Controllers: Siemens S7-1500, Honeywell Experion via Modbus TCP/PROFIBUS .

- Software Tools:

- ABB Analyzer Configuration Suite: For calibration, data logging, and diagnostics .

- SCADA Platforms: Ignition, WinCC for centralized monitoring .

Installation & Maintenance

- Deployment Guidelines:

- Mounting: DIN rail (EN 60715) for modules ; wall-mounting for full systems .

- Optical Path: Laser alignment critical for accuracy; purge gas required for window cleanliness .

- Preventive Protocols:

- Quarterly: Optical window cleaning; calibration validation .

- Annual: Full system diagnostics; firmware updates .

- Troubleshooting:

- Signal Drift: Verify purge gas flow; recalibrate per ABB Service Toolkit .

- Communication Failure: Check Modbus address conflicts or Ethernet switch faults .

Procurement & Support

- Warranty: 12 months (extendable to 36 months) .

- Global Availability: Stocked in US/EU/Asia hubs; 3–5 day delivery .

- Certifications: SIL 2 (functional safety), RoHS, CE .

Reviews

There are no reviews yet.