Product Short Description

1. Hardcore Specifications

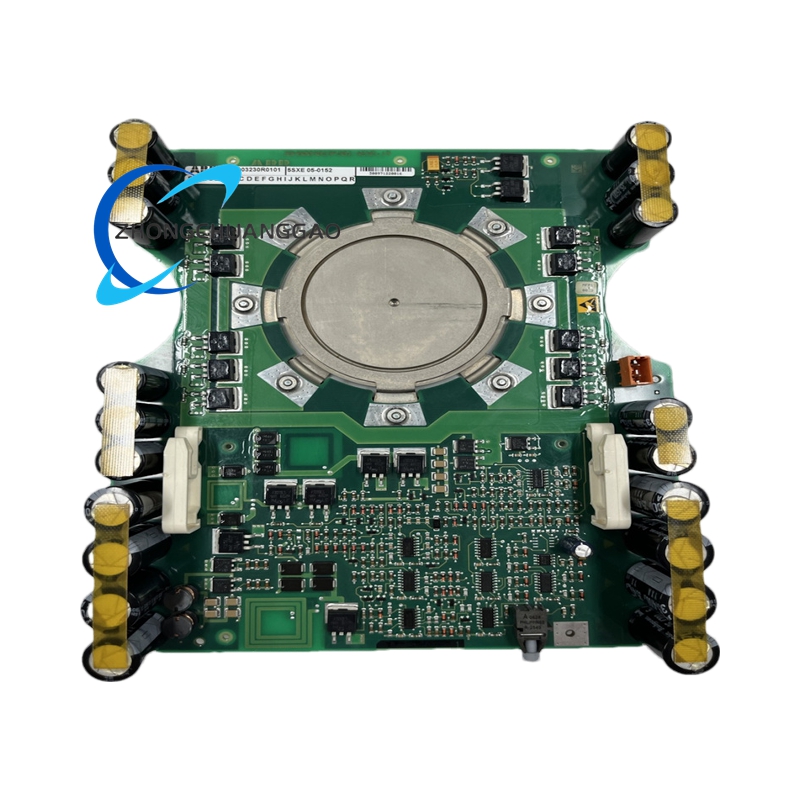

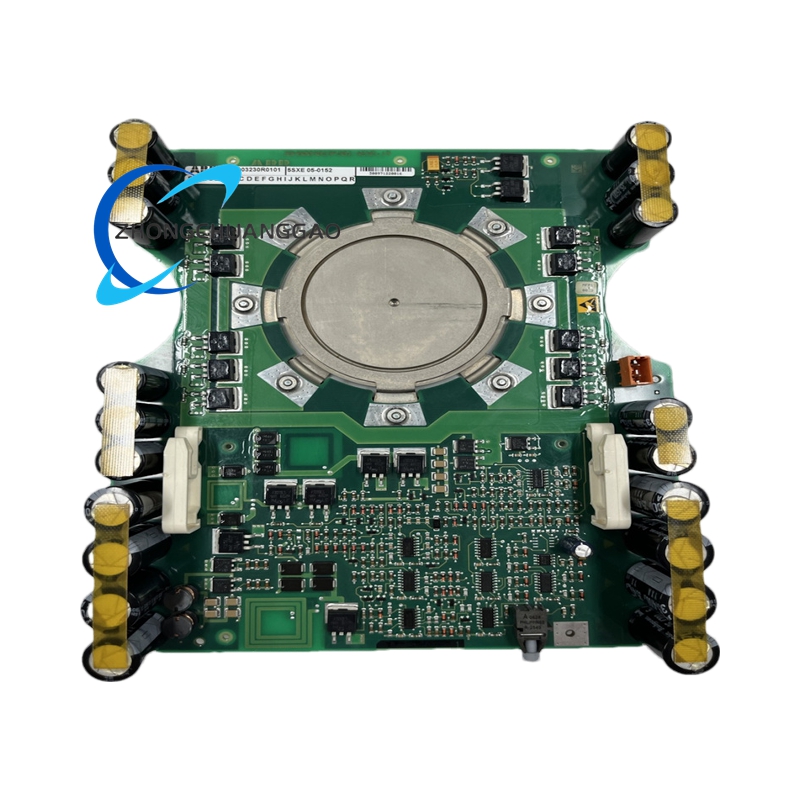

• Device: press-pack IGCT with monolithic reverse-conducting diode

• Repetitive peak blocking voltage: 6 kV

• Mean on-state current: 2 kA at 85 °C case temperature

• Surge current: 40 kA (10 ms half-sine)

• Turn-off current: 5 kA at 125 °C junction temperature

• On-state voltage drop: ≤ 1.8 V at 2 kA

• Switching frequency: up to 10 kHz (device-limited)

• Integrated gate driver: 24 VDC supply, < 5 W peak demand

• dv/dt withstand: 1 kV/µs without snubber

• di/dt withstand: 1 kA/µs turn-on

• Insulation: 9 kV RMS, 50 Hz, 1 min

• Dimensions: Ø 144 mm × 45 mm, 1.7 kg

• Cooling: double-side press-pack; forced air 1.5–2.0 m/s or water-cooled cold plate recommended

Description

2. Core Advantages

• Zero turn-off losses minimize total device losses

• Press-pack technology eliminates solder fatigue, > 30-year lifetime

• Integrated gate unit reduces wiring by 80 % and improves EMC

• Fail-to-short-circuit mode for system-level safety redundancy

• Compatible with ABB PCS6000, ACS6000, MACH2/3 control platforms

• Zero turn-off losses minimize total device losses

• Press-pack technology eliminates solder fatigue, > 30-year lifetime

• Integrated gate unit reduces wiring by 80 % and improves EMC

• Fail-to-short-circuit mode for system-level safety redundancy

• Compatible with ABB PCS6000, ACS6000, MACH2/3 control platforms

3. Typical Battlefields

• Medium-voltage variable-frequency drives: rolling-mill main drives, mining hoists, marine propulsion

• Grid FACTS: STATCOM, SVC, UPFC

• HVDC: LCC and VSC rectifiers and inverters

• High-power test benches: generator/motor dynamometers

• Renewable integration: solar and wind farm grid-connected converters

• Medium-voltage variable-frequency drives: rolling-mill main drives, mining hoists, marine propulsion

• Grid FACTS: STATCOM, SVC, UPFC

• HVDC: LCC and VSC rectifiers and inverters

• High-power test benches: generator/motor dynamometers

• Renewable integration: solar and wind farm grid-connected converters

4. Installation & Expansion

• Mounting torque: 25 N·m on both poles, uniform pressure required

• Gate driver connector: 15-pin Micro-D, pin-out per ABB standard

• Recommended heatsink flatness ≤ 25 µm, surface roughness ≤ 3.2 µm

• Parallel operation supported up to 8 devices with master-slave gate drivers

• Snubberless operation simplifies power stage design

• Remote diagnostics via gate-unit status LED and digital fault output

• Mounting torque: 25 N·m on both poles, uniform pressure required

• Gate driver connector: 15-pin Micro-D, pin-out per ABB standard

• Recommended heatsink flatness ≤ 25 µm, surface roughness ≤ 3.2 µm

• Parallel operation supported up to 8 devices with master-slave gate drivers

• Snubberless operation simplifies power stage design

• Remote diagnostics via gate-unit status LED and digital fault output

5. Ordering Package

• 5SHX1445H0001 IGCT module

• Integrated gate driver pre-mounted

• Torque wrench adapter ring

• Thermal interface foil (2 pcs)

• Installation and safety manual

• Factory test certificate (blocking, turn-off, thermal resistance)

• 5SHX1445H0001 IGCT module

• Integrated gate driver pre-mounted

• Torque wrench adapter ring

• Thermal interface foil (2 pcs)

• Installation and safety manual

• Factory test certificate (blocking, turn-off, thermal resistance)

Reviews

There are no reviews yet.