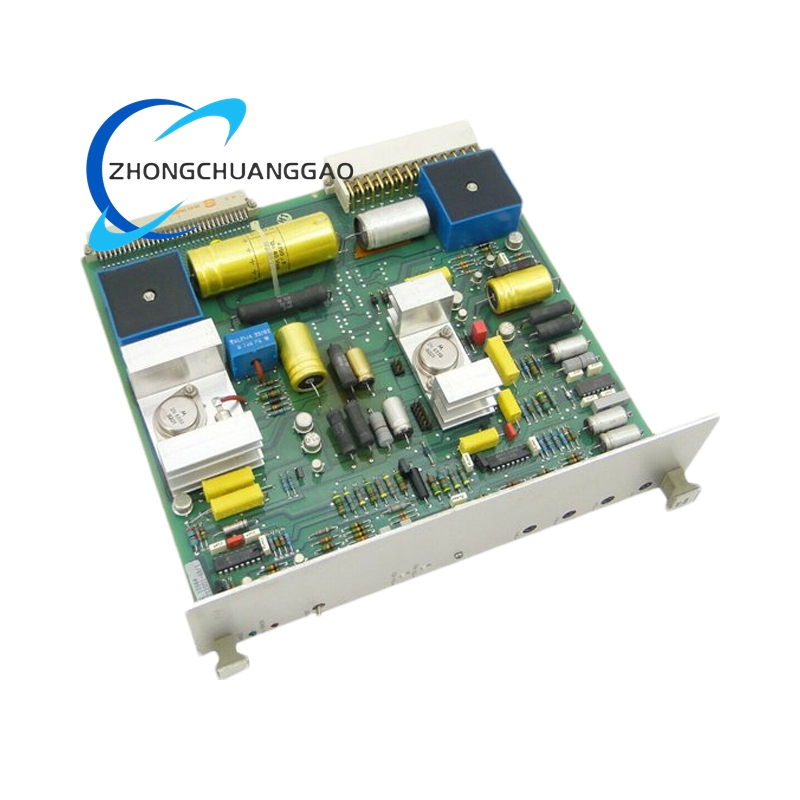

Product Short Description

Technical Specifications:

- Processor Type: 32-bit ARM Cortex-M or equivalent (depending on firmware).

- Memory:

- Flash memory: 256–512 KB (for program storage).

- RAM: 64–128 KB (for runtime data).

- Communication Interfaces:

- Ethernet (10/100 Mbps).

- CANopen, Profibus, or DeviceNet (fieldbus protocols).

- RS485/RS232 for serial communication.

- Input/Output (I/O):

- Digital inputs: 8–16 channels (24 V DC).

- Analog inputs: 4–8 channels (0–10 V or 4–20 mA).

- Pulse-width modulation (PWM) outputs: 4–6 channels.

Description

- Power Supply: 24 V DC (±10% tolerance).

- Operating Temperature: -20°C to +60°C (industrial grade).

- Protection Class: IP20 (enclosed) or IP65 (with optional housing).

- Dimensions: Approx. 150 mm × 100 mm × 50 mm (standard DIN rail mount).

- Weight: Approx. 300–500 g.

- Certifications: CE, UL, and IEC 61800-5-1 (drive safety standards).

Functional Features:

- Real-Time Control: Executes closed-loop motor control algorithms (PID, vector, or direct torque control).

- Multi-Axis Synchronization: Coordinates up to 8 axes for robotic or CNC applications.

- Fault Diagnostics: Monitors overcurrent, overvoltage, and thermal overload conditions.

- Programmability: Supports custom logic via ABB’s DriveStudio or RobotStudio software.

- Network Integration: Seamlessly connects to PLCs, HMIs, or cloud platforms for Industry 4.0.

- Energy Efficiency: Optimizes motor operation to reduce power consumption.

Application Scenarios:

- Industrial Drives:

- Variable speed control for pumps, fans, and conveyors.

- Precision positioning in packaging machines.

- Robotics:

- Motion control for ABB IRB series robot arms.

- Gripper and end-effector coordination.

- Renewable Energy:

- Solar inverter control for photovoltaic systems.

- Wind turbine pitch and yaw regulation.

- Material Handling:

- Automated guided vehicle (AGV) steering and navigation.

- Crane and hoist speed synchronization.

- Process Automation:

- Chemical mixing and extrusion line control.

- Paper mill tension and speed regulation.

Key Advantages:

- Flexibility: Adapts to diverse drive topologies (AC, DC, or servo).

- Scalability: Supports small-scale single-axis systems or large multi-axis networks.

- Durability: Withstands vibration, electromagnetic interference (EMI), and temperature extremes.

- Global Support: Backed by ABB’s technical service and firmware updates.

Industry Standards Compliance:

- Meets IEC 61131-3 (programmable logic controller standards).

- Adheres to ISO 13849 (machine safety requirements).

- Complies with IEEE 1547 (interconnection standards for distributed resources).

Reviews

There are no reviews yet.