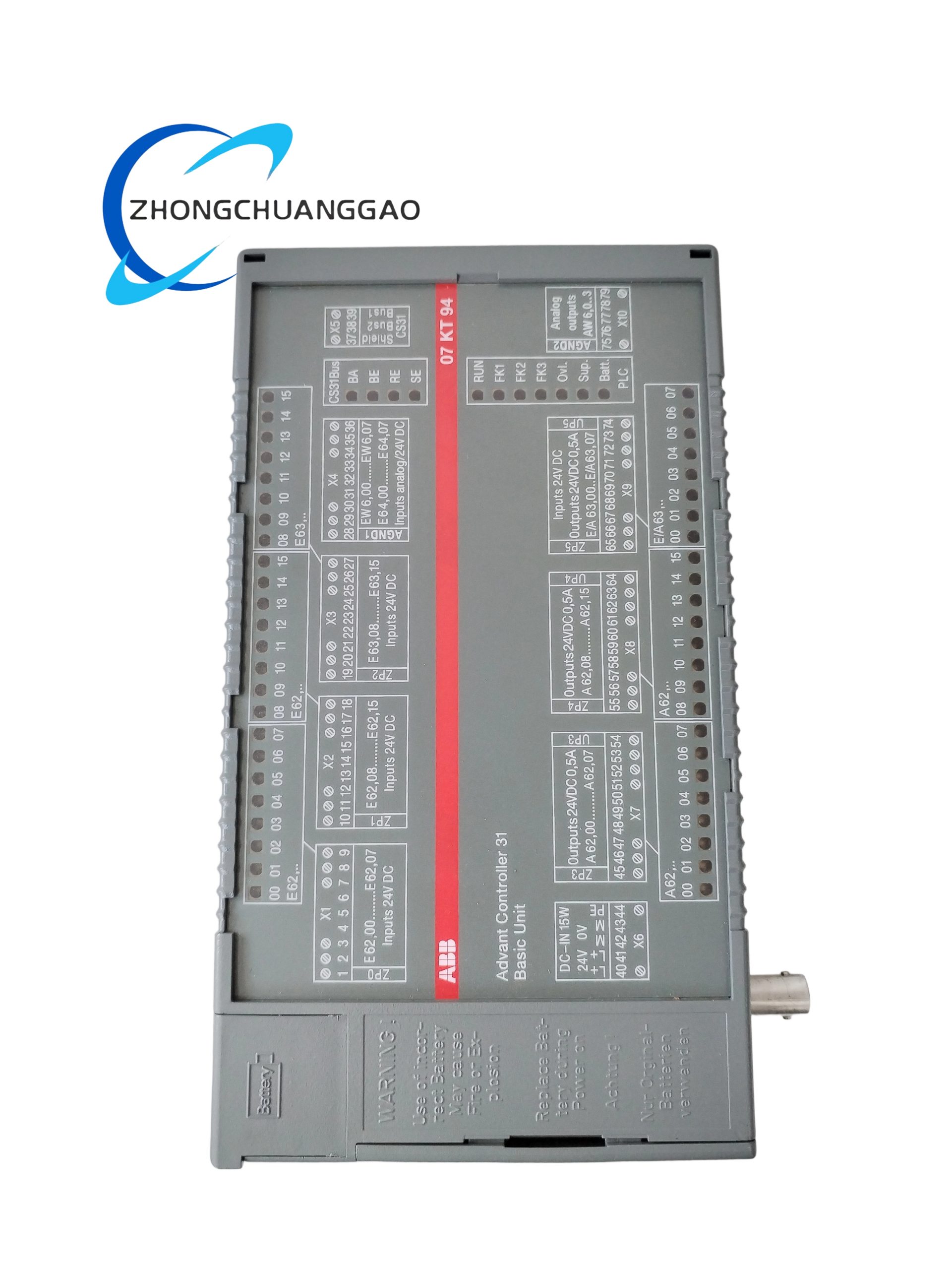

Product Short Description

Technical Specifications

- Input Channels: 4 differential input channels

- Supported Sensor Types:

- RTD (Resistance Temperature Detector): Pt100, Pt200, Pt500, Pt1000 (Class A/B)

- Thermocouple: Type J, K, T, E, R, S, B, N

- Input Range (by Sensor Type):

- Pt100: -200°C to +850°C

- Type K Thermocouple: -270°C to +1372°C

- Type J Thermocouple: -210°C to +1200°C

- Measurement Accuracy:

- RTD: ±0.1°C (at 0°C, Pt100 Class A)

- Thermocouple: ±0.2°C (at reference temperature)

Description

- Resolution: 0.1°C

- Sampling Rate: 1 sample per second per channel

- Isolation: Channel-to-channel and channel-to-backplane isolation (2.5kV AC for 1 minute)

- Power Supply: Derived from AC500 PLC backplane (5V DC)

- Power Consumption: Typical 1.2W, Maximum 1.5W

- Operating Temperature: -25°C to +60°C

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5% to 95% (non-condensing, 40°C)

- Vibration Resistance: 5-150Hz, 0.15mm amplitude (IEC 60068-2-6)

- Shock Resistance: 15g, 11ms duration (IEC 60068-2-27)

- Mounting: Integrated into AC500 PLC rack (compatible with AC500 series racks)

Function Features

- Multi-Sensor Compatibility: Supports both RTD and thermocouple sensors, eliminating the need for separate modules for different temperature-sensing technologies.

- High Measurement Precision: Delivers accurate temperature readings with low error margins, ensuring reliable data for critical control processes.

- Channel Isolation: Provides electrical isolation between channels and the backplane, preventing signal interference and protecting the PLC from voltage spikes or ground loops.

- Self-Diagnostic Capabilities: Includes built-in diagnostic functions to detect sensor faults (e.g., open circuit, short circuit) and module errors, enabling quick troubleshooting and minimizing downtime.

- Easy Configuration: Configurable via ABB’s CODESYS-based programming software (e.g., Automation Builder), allowing users to set sensor types, input ranges, and alarm thresholds through a user-friendly interface.

- Seamless PLC Integration: Designed specifically for the AC500 PLC system, ensuring plug-and-play compatibility and stable communication with the PLC CPU.

Application Scenarios

- Process Industry: Used in chemical, petrochemical, and pharmaceutical plants to monitor temperatures in reactors, pipelines, and storage tanks, ensuring compliance with process safety standards.

- Food and Beverage Production: Applied in food processing lines (e.g., baking, pasteurization) and beverage bottling plants to control temperatures during cooking, cooling, and sterilization processes, maintaining product quality and safety.

- HVAC Systems: Integrated into heating, ventilation, and air conditioning systems for commercial buildings or industrial facilities to monitor and regulate temperatures in critical areas (e.g., server rooms, cleanrooms).

- Power Generation: Used in power plants (thermal, nuclear) to monitor temperatures of generators, transformers, and cooling systems, preventing overheating and ensuring equipment reliability.

- Manufacturing: Applied in automotive, electronics, and metalworking industries to monitor temperatures in production machinery (e.g., injection molding machines, welding equipment) and ensure consistent product quality.

Be the first to review “ABB 07KT94H” Cancel reply

Reviews

There are no reviews yet.