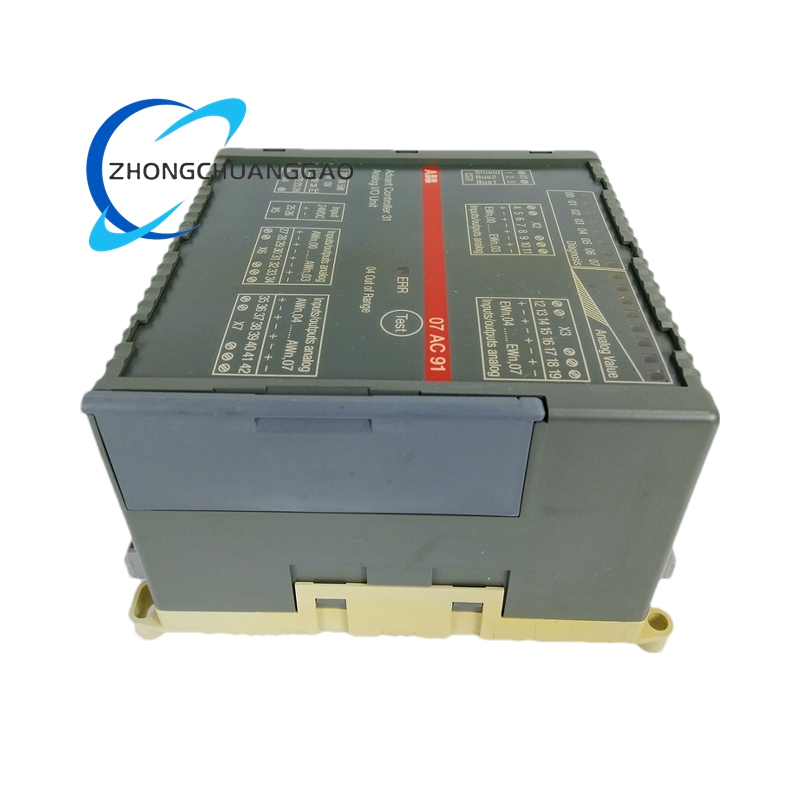

Product Short Description

Technical Specifications

- Input/Output Channels:

- 8 analog input (AI) channels (0–10V or 4–20mA).

- 8 analog output (AO) channels (0–10V or 4–20mA).

- 12-bit resolution for accurate signal conversion.

- Digital I/O:

- 16 digital input (DI) channels (24V DC).

- 16 digital output (DO) channels (24V DC).

- Power Supply:

- 24V DC input voltage.

- Power consumption: 2W (typical).

- Communication:

- Supports Modbus RTU, Profibus DP, DeviceNet, and Ethernet/IP protocols.

- Ethernet (RJ45), RS485 serial, and optional fiber-optic interfaces.

Description

- Environmental:

- Operating temperature: -25°C to +70°C (wide-temperature range).

- Storage temperature: -40°C to +85°C.

- IP20 protection rating (indoor use, no dust/water resistance).

- Mechanical:

- Dimensions: 115 x 35 x 23 mm.

- DIN rail mounting for easy integration.

Key Features

- High Precision: 12-bit resolution ensures accurate signal conversion for critical process variables.

- Modular Design: Simplifies installation, maintenance, and expansion.

- Multi-Protocol Support: Seamless integration with DCS, PLC, or SCADA systems via industrial protocols.

- Robust Construction: Withstands vibrations, electromagnetic interference, and extreme temperatures.

- Signal Isolation: Provides electrical isolation between channels to prevent interference.

- Diagnostics: Built-in LED indicators for real-time status monitoring and fault detection.

- Scalability: Supports channel expansion via stacking (up to 128 analog I/O channels per system).

Functional Capabilities

- Signal Conversion: Converts analog sensor data (e.g., voltage, current) into digital signals for PLCs.

- Control Output: Generates analog signals to regulate valves, motors, or other actuators.

- Data Acquisition: Monitors and records process variables (temperature, pressure, flow) for analysis.

- Remote Configuration: Programmable via ABB Control Builder software without onsite adjustments.

- Fault Tolerance: Self-diagnostic features and relay alarms for proactive maint

enance.

enance.

Application Scenarios

- Process Control: Regulates temperature, pressure, and flow in chemical, oil/gas, and water treatment plants.

- Manufacturing Automation: Monitors production line parameters (speed, tension, position) for quality assurance.

- Power Systems: Tracks generator output and grid frequency in energy distribution networks.

- Automotive: Controls robotic welding paths and CNC machine feed rates in assembly lines.

- Food & Beverage: Manages temperature and humidity during processing to ensure product safety.

- Mining & Metals: Drives conveyors, crushers, and pumps in harsh environments.

Compatibility

- Integrates with ABB 800xA, AC800M, and Advant Controller 31 series control systems.

- Supports third-party devices via Modbus, Profibus, and OPC UA protocols.

- Compatible with Windows/Linux programming environments (e.g., ABB DriveStudio).

Reviews

There are no reviews yet.