Product Short Description

Technical Specifications

- Input/Output:

- Speed Input: 4–20 mA analog signal or MPU sensor input (supports dual-redundant channels).

- Relay Output: 8 Form-C relay contacts for trip/alarm signaling.

- Communication: Modbus RTU protocol for integration with DCS/SCADA systems.

- Power Supply:

- Voltage: 18–36 VDC (isolated).

- Power Consumption: 30 W per module.

- Environmental:

- Operating Temperature: -20°C to +60°C (-4°F to +140°F).

- Storage Temperature: -20°C to +65°C (-4°F to +158°F).

- Enclosure: IP56-rated (dustproof and water-resistant).

- Mechanical:

- Dimensions: 330 mm (L) × 445 mm (W) × 159 mm (H).

- Weight: Less than 23 lbs (10.4 kg).

Description

Key Features

- Over-Speed Protection: Safely shuts down turbines when rotational speed exceeds predefined thresholds.

- Dual MPU Detection: Uses active/passive MPU sensors to monitor speed and acceleration, ensuring accurate fault detection.

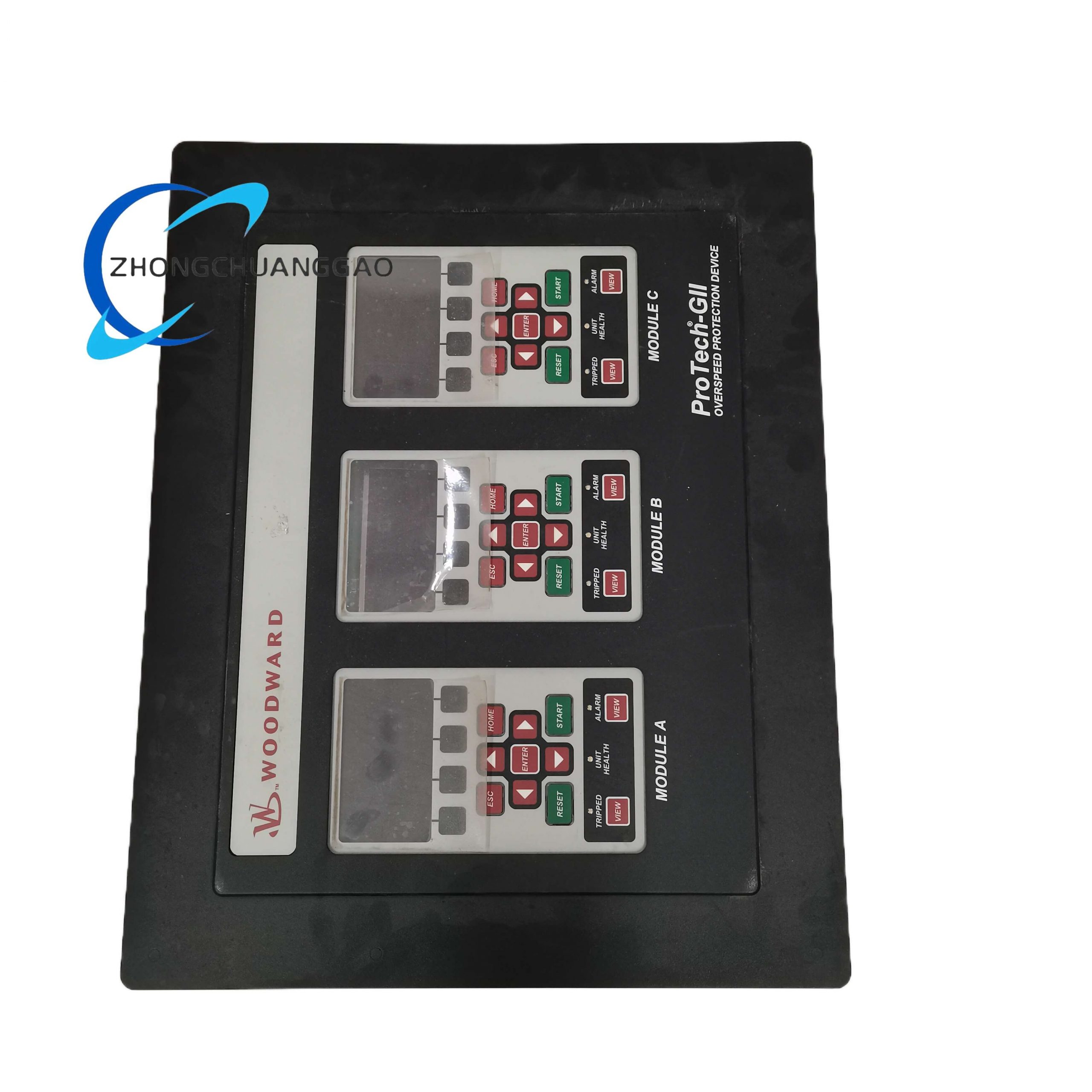

- Redundant Architecture: Three-module design with “two-out-of-three” voting logic for fail-safe operation.

- Online Maintenance: Hot-swappable modules allow replacement without interrupting system operation.

- Event Logging: Non-volatile memory stores up to 50 trip/alarm events and 20 over-speed records with real-time clock timestamps.

- Conformal Coating: Protects against sulfur contamination (H2S/SO2) in harsh environments (IEC 721-3-3 Class 3C2).

- Auto-Testing: Optional automated self-test routines verify module functionality and report results via Modbus.

Functional Highlights

- Precision Control: Adjustable speed bands and acceleration thresholds tailored to specific turbine requirements.

- Alarm Management: Configurable relay outputs for pre-trip warnings and emergency shutdowns.

- Diagnostics: Built-in tests for sensor validation and circuit integrity checks during operation.

- Scalability: Supports cascading configurations for multi-turbine systems in power plants.

Application Scenarios

- Power Generation: Controls gas turbines, steam turbines, and hydro turbines in thermal power plants and cogeneration facilities.

- Oil & Gas: Safeguards compressor turbines on offshore platforms and pipeline stations.

- Marine Propulsion: Ensures safe operation of shipboard turbines for propulsion and auxiliary power.

- Industrial Automation: Monitors rotating equipment (e.g., pumps, fans) in chemical, metallurgical, and pulp/paper plants.

- Distributed Energy: Optimizes microgrid stability in renewable energy installations (e.g., biomass, geothermal).

Advantages

- High Reliability: Redundant sensors and fail-safe logic minimize downtime in critical applications.

- Compliance: Meets international standards, including IEC 61508 SIL-3, API 670, and ATEX/IECEx for hazardous environments.

- Ease of Use: Intuitive LCD interface and Modbus connectivity simplify configuration and monitoring.

- Durability: Rugged design withstands vibration, shock, and extreme temperatures.

Reviews

There are no reviews yet.