Product Short Description

Technical Specifications

- Electrical Specifications

- It adopts a 24V DC operating voltage, which is compatible with the power supply standards of most industrial on-site equipment. Each channel can handle a current of up to 10A at 24V DC.

- It is equipped with 16 optically isolated digital input channels. The isolation rating reaches 2kV AC, and the isolation between functional earth and protective earth is at least 500V DC, while the isolation between functional earth and functional earth (logic) is at least 800V DC.

- It supports RS – 485 and Modbus communication interfaces, which can realize efficient data exchange with other industrial control components and ensure smooth information transmission in the system.

- Physical Specifications

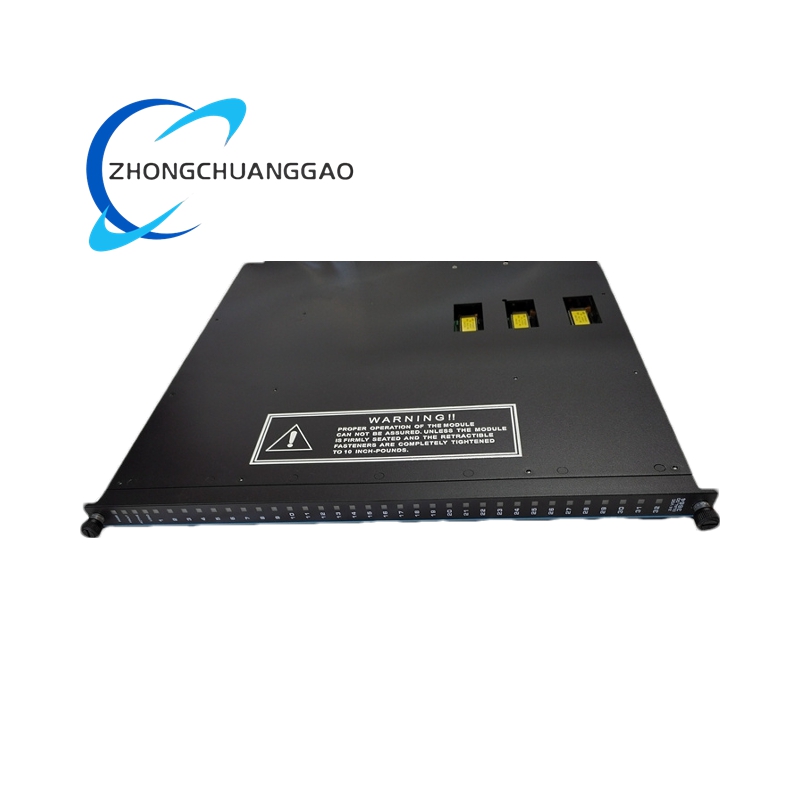

- The module has a compact structure. Relevant similar models of the same series have dimensions of about 6.2 cm × 42 cm × 17.7 cm, and the weight of such modules is about 2.32 kg, which is convenient for installation in standard industrial racks.

- It adopts a modular plug-in design that matches the Triconex system rack, and is equipped with mechanical keying, which can prevent incorrect installation in the configured base plate and ensure the correctness of installation.

Description

- Environmental Specifications

- The operating temperature range is -40°C to 85°C, which can adapt to extreme temperature environments such as cold outdoor industrial sites and high-temperature indoor workshops.

- It has good environmental adaptability and can maintain stable performance even in environments with large humidity fluctuations, which is suitable for coastal industrial areas and water treatment plants with high humidity.

Functional Characteristics

- Accurate Signal Acquisition and Anti-Interference

- Each of the 16 input channels can independently isolate and verify the signal state. The low threshold sensitivity enables it to accurately detect weak digital signals, avoiding signal distortion and false detection caused by mutual interference between channels.

- The high-voltage isolation design and strong noise immunity can effectively resist electromagnetic interference from on-site high-power equipment and frequency converters, ensuring the accuracy and stability of signal acquisition in complex industrial electromagnetic environments.

- Comprehensive Fault Diagnosis and High Safety

- It is equipped with continuous self-test and loop-back verification functions, which can continuously monitor the operating status of each channel and the internal components of the module. When a fault occurs, it can quickly detect and report the fault information.

- Each output is equipped with a 0.75A fast-acting fuse. When an overcurrent situation of up to 0.7A per channel occurs, the fuse can be triggered in time to protect the module and the connected external equipment from damage.

- Flexible Integration and Easy Maintenance

- It can be seamlessly integrated into the Triconex safety control platform and is fully compatible with other Triconex series modules, which is convenient for users to expand and upgrade the existing system.

- It supports hot-swapping and hot-spare module configuration. Maintenance personnel can replace the faulty module online without shutting down the entire system, and the hot-spare module can take over the work immediately when a fault occurs, minimizing production downtime.

Application Scenarios

- Oil and Gas Industry

- It is applied to the emergency shutdown systems and fire and gas detection systems of offshore drilling platforms. It collects signals from on-site gas sensors and pressure sensors, and transmits the abnormal signals to the upper controller in time to trigger emergency measures such as platform shutdown.

- It is used in the safety control system of onshore oil depots. It monitors the switch state of oil storage tank valves and the operation state of oil transfer pumps, ensuring the safe operation of oil storage and transfer processes.

- Chemical and Petrochemical Industry

- It is integrated into the safety control system of chemical reactors. It collects data such as the temperature and pressure of the reactor in real time and sends the data to the main control system to ensure that the chemical reaction is carried out within the safe parameter range.

- It is deployed in the safety monitoring system of petrochemical refining units. It acquires signals from various detection instruments on the refining line and cooperates with the fire protection system to avoid fire and explosion accidents caused by equipment failures.

- Power Industry

- It is used in the power distribution and safety control system of thermal power plants. It collects the operating state signals of generators, transformers and other key equipment, and provides data support for the stable operation and fault early warning of the power generation system.

- It is applied to the auxiliary safety system of nuclear power plants. It monitors the switch state of cooling system valves and the operation state of circulating pumps, ensuring the normal operation of the nuclear power plant’s temperature control system.

- General Industrial Automation

- It is used in the safety monitoring system of metallurgical factories. It collects the temperature, pressure and other process signals of blast furnaces and converters, helping to stabilize the metallurgical process and improve product quality.

- It is integrated into the automatic control system of large-scale manufacturing workshops. It acquires the operation state signals of various production lines and mechanical equipment, and realizes the real-time monitoring and abnormal alarm of the production process.

Be the first to review “Triconex RO3451 Digital Input Module” Cancel reply

Reviews

There are no reviews yet.