Product Short Description

Technical Specifications

- Electrical Parameters

- Operating Voltage: It adopts a 24VDC working voltage, and some configurations can also adapt to 125VDC standard digital signal levels, which is consistent with the power supply specifications of most industrial on-site equipment.

- Input Configuration: It is equipped with 32 digital input points, which can simultaneously receive digital signals from multiple on-site devices to meet the needs of multi-point signal collection in industrial scenarios.

- Input Type: It supports dry contact and photoelectric isolation input, and the integrated signal isolation circuit can effectively reduce signal interference and noise.

- Communication Protocols: It is compatible with multiple communication protocols such as Modbus, Ethernet, and OPC, facilitating data exchange and integration with other control systems and equipment.

Description

-

- Physical and Environmental Parameters

- Operating Temperature Range: It can operate stably within the temperature range of -40°C to 70°C, adapting to the temperature fluctuations of both indoor industrial control rooms and outdoor harsh construction sites.

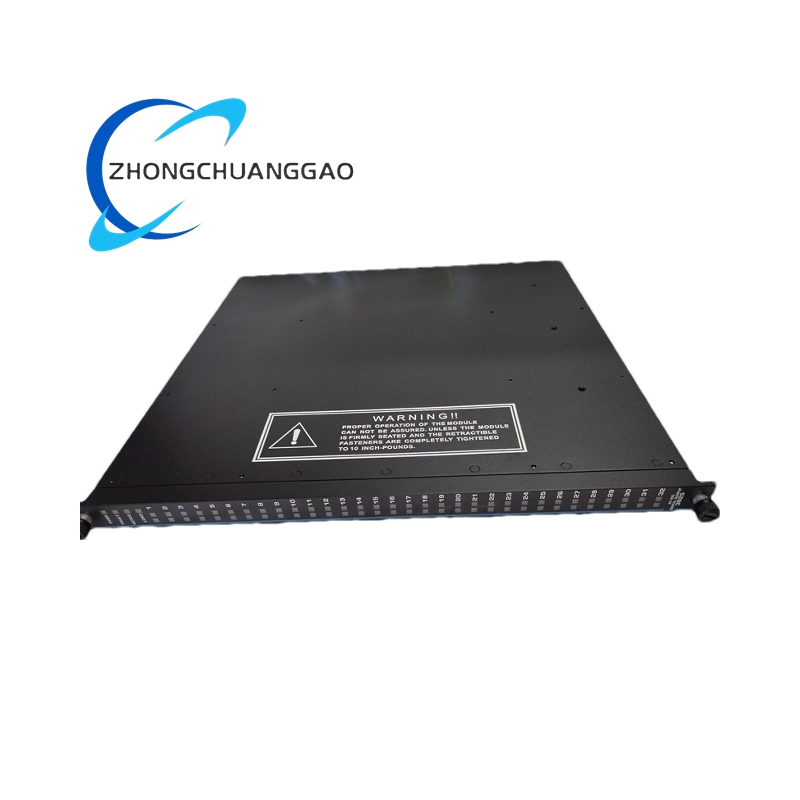

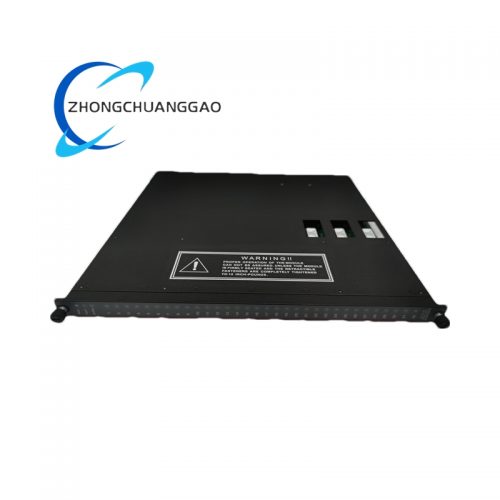

- Physical Dimensions: The size is 300 x 150 x 75mm, and the compact size allows it to be easily installed in limited control cabinet spaces.

- Weight and Protection Level: It weighs approximately 2 kilograms, and its protection level reaches IP66, which can resist the erosion of dust and water splashes in industrial environments and ensure long-term stable operation.

- Physical and Environmental Parameters

- Functional Features

- Triple Modular Redundancy for High Fault Tolerance: It adopts triple modular redundancy architecture and supports redundant configuration with dual power supplies and processors. If a single power supply, processor, or a single system branch fails, the system can continue to operate without interruption, and maintain the ability to monitor and process input signals, thus greatly improving the fault tolerance of the entire control system.

- Stable Signal Transmission with Strong Anti-Interference: The built-in signal conditioning and isolation circuits can filter out external electromagnetic interference and signal noise from industrial sites. This ensures the accuracy and stability of the collected digital signals during transmission, avoiding misjudgments of the main control system caused by distorted signals.

- Easy Installation and Convenient Maintenance: It is designed to be installed on the DIN rail of the control cabinet or panel, enabling quick installation and disassembly. Its modular design allows maintenance personnel to replace the module independently when a fault occurs, which shortens the system downtime and improves maintenance efficiency.

- Flexible Expansion and Compatibility: It can flexibly combine with other modules in the Triconex series such as digital output modules and analog output modules. Meanwhile, the support for multiple communication protocols enables it to connect with various sensors, actuators, and controllers, realizing convenient expansion and upgrading of the control system.

- Application Scenarios

- Oil and Gas Industry: It is widely used in oil drilling platforms and refineries. It collects digital signals such as the on-off state of pipeline valves and the fault alarm signals of pumping equipment, and transmits them to the Triconex main control system. It ensures the timely detection of potential risks such as pipeline leakage and equipment failure, and provides a guarantee for the safe operation of the entire oil and gas exploitation and refining process.

- Chemical Industry: It is deployed in chemical plants to monitor the operating status of chemical reactors, storage tanks, and pipeline systems. It collects digital signals such as the pressure switch signals of reactors and the level alarm signals of storage tanks. When abnormal parameters are detected, it can timely feed back information to trigger corresponding safety measures and prevent dangerous situations such as chemical leakage and reaction out of control.

- Power Industry: It is applied to power plants and substations. It is responsible for collecting digital signals such as the operation status of generators, the switching state of transformers, and the flow alarm of cooling water. It ensures that the power control system can grasp the equipment status in real time, avoids large-scale power outages caused by equipment failures, and maintains the stable operation of the power grid.

- Nuclear Power Industry: It is used in nuclear power plant safety monitoring systems. It monitors digital signals related to nuclear safety, such as reactor coolant pressure alarms and radiation level detection signals. Its high safety level and redundant design can ensure that the system still works reliably in extreme cases, preventing nuclear safety accidents.

- Manufacturing Industry: It is integrated into automated production lines. It collects digital signals such as the position signals of conveying equipment on the production line and the fault signals of packaging machinery. It helps the production control system timely find production line failures, realize rapid alarm and shutdown, and ensure the safety of production equipment and the stability of product quality.

Be the first to review “Triconex 9566-810 Redundant Digital Input Module” Cancel reply

Reviews

There are no reviews yet.