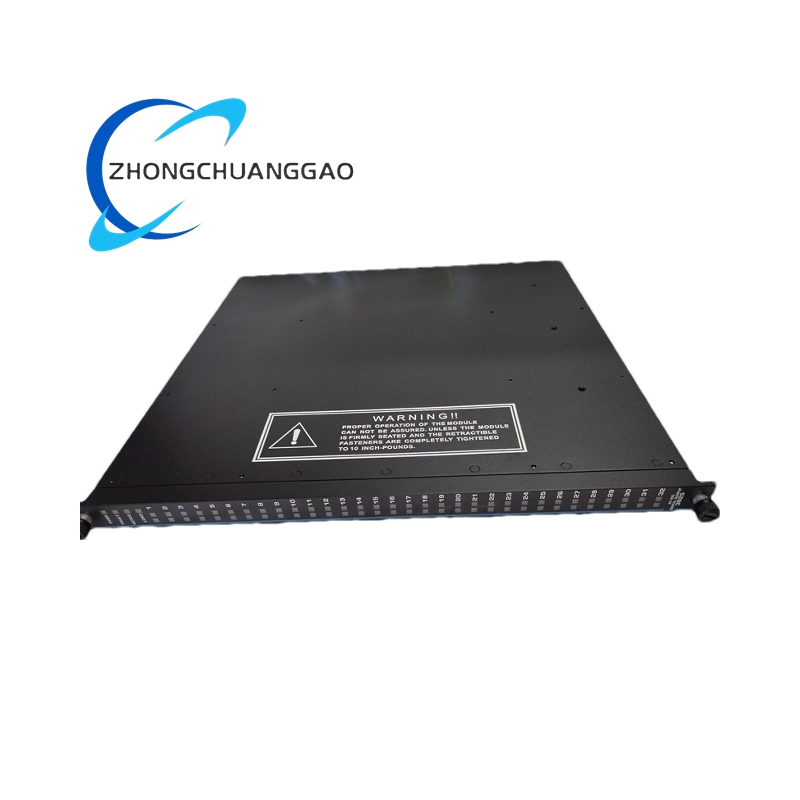

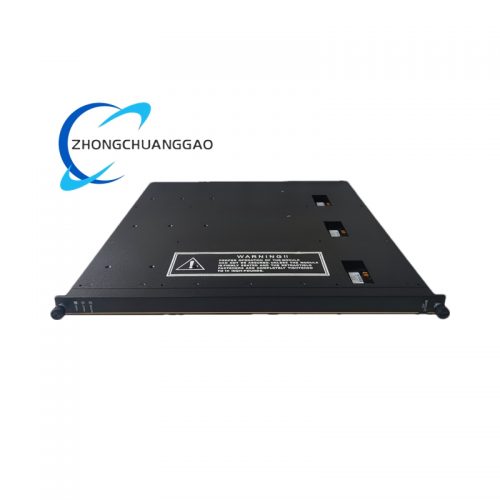

Product Short Description

Technical Specifications

- Electrical Parameters

- Power Supply Requirements: It adopts a 24 – volt direct current input voltage and provides a 5 – volt direct current output voltage, which matches the power supply standards of most industrial control systems and ensures stable power supply for its own operation and signal processing.

- Current Capacity: The output current is rated at 2 amperes, which can provide sufficient current support for the connected peripheral components and ensure the effective operation of the associated control circuits.

- Communication Protocol: It is equipped with Modbus communication protocol, which realizes smooth data interaction and information transmission with other modules in the Triconex system and external related control equipment.

Description

-

- Environmental and Physical Parameters

- Operating Temperature Range: It can operate stably within the range of -40°C to 85°C, adapting to the extreme temperature fluctuations common in outdoor industrial sites and indoor high – temperature workshop environments.

- Structural Compatibility: It is designed with a structure matching Triconex standard industrial control chassis. It can be smoothly installed into Triconex’s dedicated chassis slots and is compatible with the backplane communication interface of the chassis to achieve fast integration into the existing system.

- Durability Standards: The shell and internal components are made of industrial – grade wear – resistant and corrosion – resistant materials, which can resist the erosion of oil mist, dust and other pollutants in industrial environments and maintain long – term stable performance.

- Environmental and Physical Parameters

- Functional Features

- Triple Modular Redundancy Based Fault Tolerance: It adopts a triple modular redundancy structure composed of three identical system branches. Any fault occurring in a single branch will not affect the normal operation of the entire module. The system can automatically shield faulty components and ensure continuous output of correct control signals.

- Integrated Safety Logic Control and Monitoring: It undertakes core safety logic control tasks. It can receive on – site sensor signals, execute preset safety control programs, and monitor the operating status of the connected equipment in real time. It promptly identifies abnormal signals such as equipment overload and abnormal process parameters.

- Seamless Compatibility with Triconex Ecosystem: It can achieve plug – and – play connection with Triconex’s controllers, I/O modules and other products. It does not require additional adaptation hardware or complex programming modifications, which simplifies the construction process of the entire safety control system and improves the efficiency of system deployment.

- Efficient Fault Detection and Rapid Response: It integrates a high – sensitivity fault detection mechanism. It can quickly locate faults in internal circuits, communication links and connected external equipment. Once a fault is detected, it will immediately send fault signals to the upper – level control system while triggering corresponding protective actions to avoid the expansion of fault impacts.

- Application Scenarios

- Oil and Gas Industry: It is deployed in oil extraction platforms, natural gas gathering stations and long – distance oil and gas transmission pipeline systems. It is used to control and monitor the operation of pumping units, valve groups and pressure detection equipment. It can trigger emergency shutdown procedures immediately when abnormal pressure or leakage signals are detected, preventing major accidents such as oil and gas explosions and environmental pollution.

- Petrochemical and Chemical Industry: It is integrated into the control systems of chemical reactors, distillation towers and combustion systems in chemical plants. It executes safety logic for parameters such as reaction temperature, pressure and material concentration. When the parameters exceed the safety threshold, it can quickly cut off the feeding system or start the emergency cooling device to avoid dangerous situations such as out – of – control chemical reactions and fires.

- Power Generation Industry: It is applied to the safety control systems of thermal power plants, nuclear power plants and hydropower stations. In thermal power plants, it monitors the operation status of boilers and turbines. In nuclear power plants, it is involved in the safety protection of reactor systems. It ensures the stable operation of key power generation equipment and triggers protective measures in time when abnormalities occur to avoid large – scale power outages and equipment damage.

- Metallurgical Industry: It is installed in the control systems of blast furnaces, converters and rolling mills in metallurgical plants. It adapts to the high – temperature and high – interference industrial environment of metallurgical sites. It monitors the temperature of smelting furnaces, the speed of rolling mills and other key parameters. It adjusts the operation parameters in real time through safety logic control and ensures the safety of the smelting and rolling processes.

- Pharmaceutical and Chemical Industry: It is used in the automated production lines of pharmaceutical factories, especially in the control links of high – precision chemical reaction kettles and sterile production equipment. It monitors the temperature, mixing speed and other parameters in the pharmaceutical process. It ensures that the production process meets GMP standards and avoids product quality problems and safety risks caused by parameter fluctuations.

Be the first to review “Triconex 9566-850 Industrial Safety Control Card Module” Cancel reply

Reviews

There are no reviews yet.