Product Short Description

Technical Specifications

- Module Core Parameters

- Processor and Memory: The 9000011 – 000 processor module under the series adopts a high-performance processing architecture. The 9753 – 1 I/O accessory is equipped with relevant supporting processing components and 1MB memory to ensure efficient data transmission and processing.

- Input and Output Performance: Digital input module models under the series can implement self-test functions. When testing for stuck – on inputs, the internal circuit switch closes to enable the optical isolation circuit to read zero input signals. The 3611E digital output module in the series uses a quadruplicated output switch with mechanical power relays to generate voting output signals.

- Communication Interfaces: Relevant modules in the series support multiple communication methods such as Ethernet (802.3) and serial ports (RS – 232/RS – 485/RS – 422). Some accessories are compatible with Modbus and Profibus communication protocols to realize seamless data interaction with the main control system.

Description

-

- Physical and Environmental Parameters

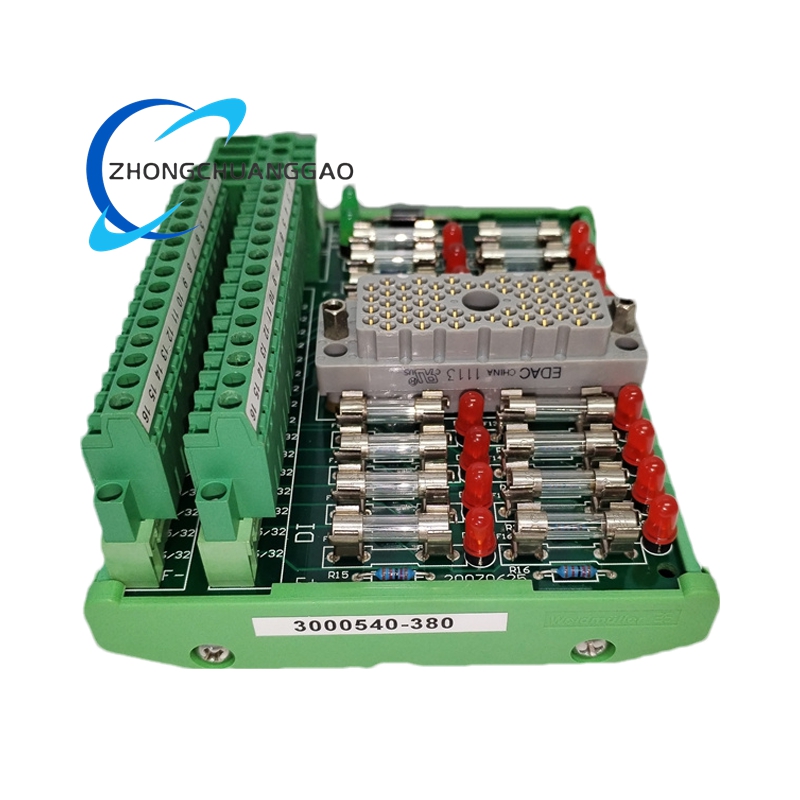

- Individual Accessory Specifications: The 9753 – 1 wiring terminal in the series has dimensions of 10.2mm × 12.7mm × 6.4mm and a weight of approximately 1 gram. The 9000011 – 000 module weighs 1000 grams, and the external drive module variant 9000 – EXF has dimensions of 100mm × 60mm × 30mm and a weight of 0.2kg.

- Temperature Adaptability: The operating temperature range of key components such as the 9753 – 1 wiring terminal is -40°C to 85°C. The overall series can adapt to the common industrial high and low temperature environments and maintain stable performance.

- Electrical Ratings: The 9000 – EXF external drive module supports 24VDC operating voltage and 5A operating current, with a load capacity of up to 1000VA. The 9753 – 1 wiring terminal has a voltage rating of up to 300V and a current rating of up to 10A, and the applicable wire diameter range is 0.5mm² to 2.5mm².

- Physical and Environmental Parameters

- Functional Features

- Self – test and Fault Detection: The digital input modules of the series can automatically detect stuck – on circuit conditions. During the self – test process, the last data reading is frozen in the I/O communication processor to ensure the accuracy of the test results. The 3611E digital output module is equipped with voltage and current loopback circuits to comprehensively detect faults of output switches, field circuits and loads.

- High Compatibility and Scalability: The series is fully compatible with various chassis of Triconex systems. Its modular design allows for flexible combination with other Triconex modules. It can also achieve universal connection with major distributed control systems, supporting the expansion of system functions and meeting the needs of different scale industrial control scenarios.

- Reliable Connection and Transmission: The 9753 – 1 wiring terminal in the series adopts high – quality materials and spring – type connection design, which ensures reliable connection between I/O modules and field equipment. The optical isolation circuit is configured inside the digital input module to reduce signal interference and ensure the integrity and stability of data transmission.

- Hot – Swap Support: Key modules such as the 3611E digital output module in the series support hot – swap operation. Maintenance personnel can replace the module without shutting down the entire system, which minimizes system downtime and ensures continuous industrial production.

- Application Scenarios

- Oil and Gas Industry: The series modules are installed in emergency shutdown systems and high – integrity pressure protection systems of oil and gas exploitation sites and transportation pipelines. The digital input modules collect pressure and leakage signals of pipelines and wellheads in real time, and the wiring terminals ensure stable connection between sensors and the main control system, preventing major accidents such as pipeline explosion.

- Chemical Industry: It is applied to reactor control systems and combustion management systems in chemical plants. The series modules connect temperature, concentration and other parameter collection devices with the central control system. When abnormal parameters occur, they can quickly transmit signals to trigger corresponding safety measures and avoid dangerous situations such as out – of – control chemical reactions.

- Power Generation Industry: It is deployed in safety protection systems of thermal power plants and nuclear power plants. It is responsible for the signal transmission between monitoring equipment of boilers, turbines and nuclear reactors and the main control system. Its high reliability and stability meet the strict safety requirements of the power industry and ensure the continuous and safe operation of power generation units.

- Pharmaceutical Industry: It is used in automated production lines and safety control systems of pharmaceutical factories. The series modules realize the connection between pharmaceutical reaction equipment, temperature control devices and the central control system. They ensure that the production process parameters are stably collected and transmitted, and maintain the safety and stability of the pharmaceutical production process in accordance with relevant industry standards.

- Metallurgical Industry: It is integrated into the control systems of smelting furnaces and rolling mills. The series modules adapt to the high – interference industrial environment of metallurgical workshops. They complete the signal interaction between high – temperature detection equipment, material conveying equipment and the main control system, ensuring the continuity and safety of the metallurgical production process.

Be the first to review “Triconex 9000 Series Industrial Safety I/O and Accessory Suite” Cancel reply

Reviews

There are no reviews yet.