Product Short Description

Technical Specifications

- Electrical Parameters

- Input Signal Type: It specializes in receiving 24V DC dry contact digital signals, which is compatible with most standard discrete signal output devices in industrial fields and reduces the need for signal conversion accessories.

- Input Channel Configuration: It is equipped with 16 independent digital input channels, which can simultaneously collect signals from multiple on – site devices and meet the signal acquisition needs of medium – scale control loops.

- Channel Isolation Performance: Each input channel is designed with independent electrical isolation, and the isolation voltage reaches 2500V AC. This design prevents cross – interference between channels caused by voltage fluctuations and electromagnetic noise on industrial sites.

- Response Time: The input response time is within 10 milliseconds. This fast response speed ensures that the controller can immediately capture changes in the operating status of on – site equipment and implement control strategies in a timely manner.

Description

-

- Physical Parameters

- Installation Method: It adopts a standard rack – mounted design that is fully compatible with Triconex Tricon series host chassis and expansion chassis, enabling quick insertion and fixing without custom – made mounting parts.

- Structural Design: It follows the uniform dimension standard of Triconex I/O modules, with a compact structure that can be closely installed with other Triconex modules in the chassis, effectively saving the installation space in the control cabinet.

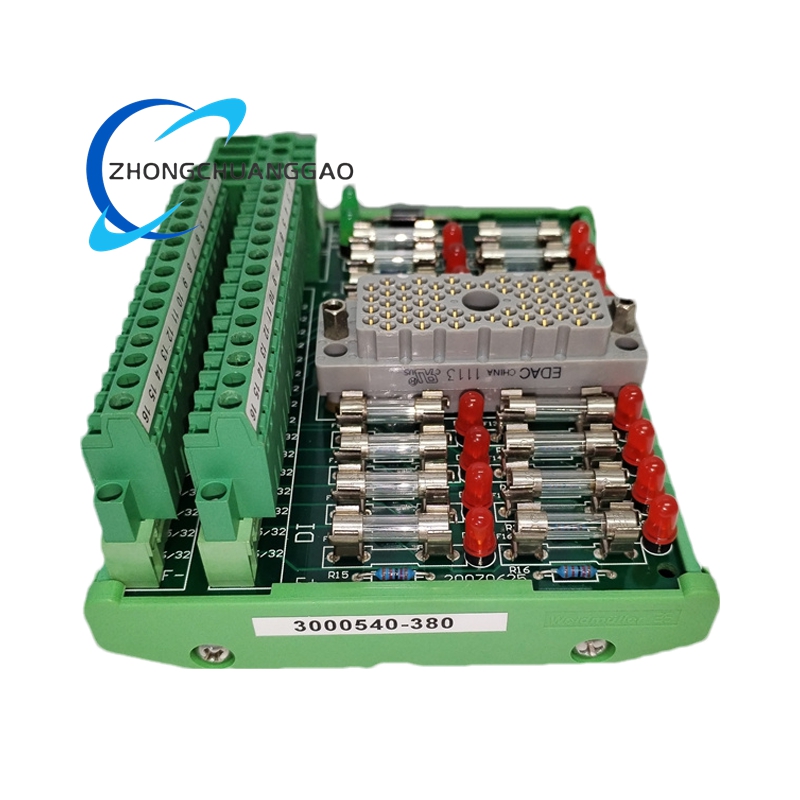

- Terminal Type: It uses industrial – grade spring – loaded terminals that provide firm connections. These terminals can resist the vibration impact of industrial sites and avoid poor contact caused by long – term operation.

- Environmental Parameters

- Operating Temperature: It can operate stably within the range of – 40°C to 75°C, adapting to extreme temperature conditions in cold outdoor oilfields and high – temperature chemical workshops.

- Humidity Adaptability: It works normally in an environment with a relative humidity of 5% – 95% without condensation, which is suitable for humid working environments such as coastal industrial zones and water treatment plants.

- Vibration Resistance: It can withstand a vibration amplitude of 2g within the frequency range of 10Hz – 150Hz, meeting the vibration resistance requirements of industrial sites such as pipeline pump rooms and machine workshops.

- Physical Parameters

- Functional Features

- Triple Modular Redundancy Ensures Signal Accuracy: The internal triple – channel parallel operation mode realizes the “two – out – of – three” voting mechanism for collected signals. When one channel malfunctions, the other two normal channels can still output accurate signals, completely avoiding signal errors caused by single – point component failures.

- Built – in Comprehensive Self – diagnostic Function: It continuously monitors the working status of each input channel, internal circuits, and power supply. When abnormalities such as channel open circuits, power supply instability, or signal distortion occur, it immediately sends fault codes to the upper – level controller, helping maintenance personnel quickly locate and resolve problems.

- Seamless System Compatibility: It is fully compatible with Triconex Tricon, Tricon CX, and other series of control systems. It can be directly installed in the existing Triconex chassis without modifying the system program or adjusting the hardware configuration, reducing the difficulty of system expansion and upgrading.

- Industrial – grade Durability: The shell is made of high – strength flame – retardant engineering plastics. It not only has good impact resistance but also meets the industrial flame – retardant standard, preventing the spread of fire in case of accidents in the control cabinet and protecting the safety of the entire system.

- Application Scenarios

- Petrochemical Production Plants: It is widely used in the safety interlock systems of chemical reactors, distillation towers, and storage tanks. It collects signals from liquid level limit switches, gas leakage detection sensors, and emergency shutdown buttons. When dangerous signals are detected, it transmits them to the controller in real – time to trigger chain reactions such as equipment shutdown and alarm, avoiding leakage and explosion accidents.

- Oil and Gas Transportation Pipelines: It is installed in the on – site control boxes of long – distance oil and gas pipelines. It collects signals from pipeline pressure switches, valve position sensors, and pipeline anti – theft detection devices. It ensures that the remote control center can grasp the operation status of the pipeline in real – time and quickly handle abnormal conditions such as pipeline blockage and valve failure.

- Thermal Power and Nuclear Power Plants: It is applied to the auxiliary control systems of boilers and steam turbines. It collects digital signals from boiler safety door position sensors, turbine bearing temperature switches, and water supply pump operation status detectors. It provides reliable data support for the stable operation of power generation equipment and ensures the continuous and safe supply of electricity.

- Mining and Metallurgical Industry: It is integrated into the control systems of mineral processing equipment and smelting furnaces. It collects signals from conveyor belt deviation switches, smelting furnace door closing sensors, and material level limit switches. It realizes real – time monitoring of the production process, avoids equipment damage caused by abnormal operation, and ensures the safety of the production line.

Be the first to review “Triconex 4000212-050 Triple Modular Redundancy Digital Input Module” Cancel reply

Reviews

There are no reviews yet.