Product Short Description

Technical Specifications

- Electrical Parameters

- Input Signal Type: It is specialized in collecting dry contact digital signals, which is the most common discrete signal type in industrial sites and can be directly connected to most standard industrial digital sensing equipment.

- Operating Voltage: It adopts a 24V DC power supply, which is consistent with the universal power supply standard of industrial control systems and facilitates unified power management of the entire control cabinet.

- Input Response Time: The maximum input response time is 10 milliseconds. This fast response speed ensures that the controller can promptly obtain changes in on – site equipment status and make timely control responses.

- Input Channel Isolation: Each input channel is equipped with independent electrical isolation protection. The isolation voltage reaches 2500V AC, which can effectively prevent mutual interference between channels and avoid signal distortion caused by electrical noise.

Description

-

- Physical Parameters

- Installation Type: It adopts a standard rack – mounted installation method that is compatible with the unified chassis of the Triconex system. It can be quickly installed and fixed without additional customized installation brackets.

- Structural Dimensions: It follows the uniform size standard of Triconex I/O modules. The compact design allows it to be installed side by side with other modules in the control cabinet, which greatly improves the space utilization rate of the cabinet.

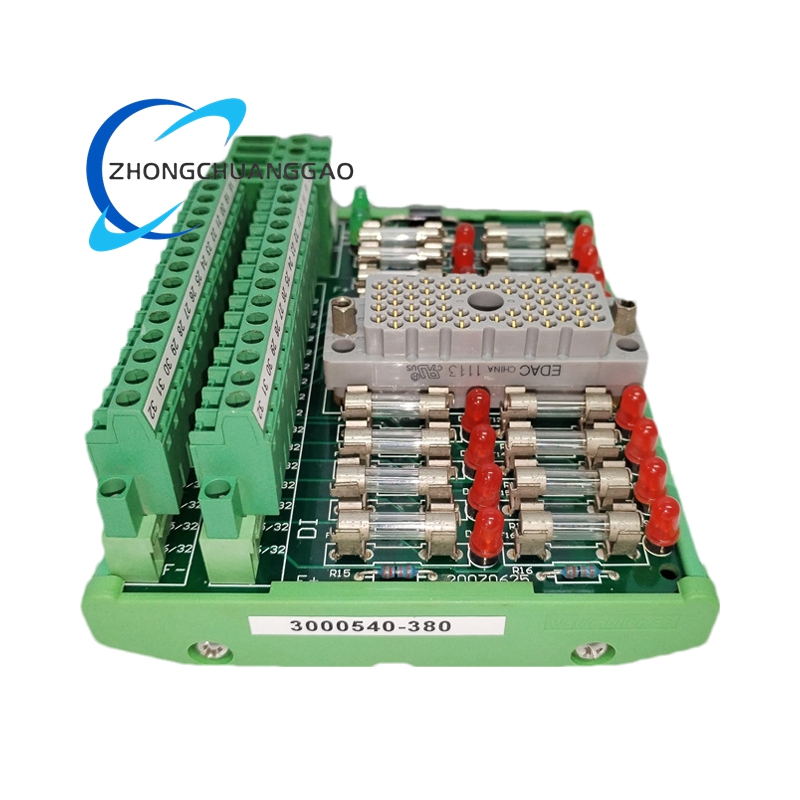

- Connector Type: It is equipped with industrial – grade spring – loaded terminals. These terminals have strong anti – loosening performance and can maintain stable connections even under the vibration conditions of industrial sites.

- Environmental Parameters

- Operating Temperature: It can maintain normal signal acquisition performance within the temperature range of – 40°C to 75°C, adapting to extreme temperature environments such as cold outdoor oilfields and high – temperature chemical workshops.

- Storage Temperature: The safe storage temperature range is – 55°C to 85°C. This ensures that the module will not be damaged due to extreme temperatures during long – term storage or long – distance transportation.

- Humidity Adaptability: It can operate normally in an environment with a relative humidity of 5% – 95% without condensation. This makes it suitable for humid working conditions such as coastal petrochemical plants and water treatment facilities.

- Physical Parameters

- Functional Features

- Triple Modular Redundancy Ensures Signal Reliability: The module adopts triple modular redundancy technology in its internal circuit and signal acquisition design. The three channels simultaneously collect and verify the same digital signal. Through a majority voting mechanism, it filters out abnormal signals caused by interference or component failure, ensuring the accuracy of the transmitted digital signals to the controller.

- Channel Isolation Prevents Interference: The independent electrical isolation design for each channel not only isolates interference between channels but also isolates the module from the external circuit. It can resist the impact of voltage surges and electromagnetic interference on the industrial site, ensuring the stability of the module’s long – term operation.

- Easy Troubleshooting with Self – diagnostic Function: It is equipped with a full – range self – diagnostic function. It continuously monitors the working status of each input channel and its own circuit. When a channel failure, power supply abnormality, or signal interruption occurs, it will immediately send a fault code to the upper – level system, enabling maintenance personnel to quickly locate the faulty part.

- Hot – swap Supports Uninterrupted Production: It supports hot – swap operation in the Triconex system. When the module needs to be maintained or replaced due to a fault, it can be removed and installed without shutting down the entire control system, which avoids production losses caused by system downtime.

- Application Scenarios

- Petrochemical Industry: It is installed in the safety interlock systems of chemical reactors, distillation towers, and storage tanks. It collects digital signals from emergency stop buttons, liquid level limit switches, and gas leakage detection sensors. It promptly transmits dangerous status signals to the controller to trigger shutdown or alarm actions and prevent explosion and leakage accidents.

- Oil and Gas Industry: It is applied to offshore drilling platforms and onshore oilfield gathering and transportation systems. It collects discrete signals from pipeline pressure switches, valve position sensors, and wellhead emergency cut – off devices. It ensures that the central control system can grasp the operation status of key equipment in real – time and respond to potential safety hazards in a timely manner.

- Power Generation Industry: It is used in the auxiliary control systems of thermal power plants and nuclear power plants. It collects digital signals from boiler safety door position switches, turbine bearing temperature switches, and water pump operation status sensors. It provides accurate on – site data support for the stable operation of power generation equipment and ensures the safe and continuous supply of electricity.

- Automated Manufacturing Industry: It is integrated into the control systems of automated production lines. It collects signals from workpiece in – place sensors, conveyor belt speed switches, and robotic arm action limit switches. It ensures the coordinated operation of various equipment in the production line and improves the stability and efficiency of automated production.

- Marine Engineering: It is used in the marine power and cargo control systems of large ships and offshore engineering platforms. It collects digital signals from marine engine status switches, cabin fire detection sensors, and cargo hold door closing sensors. It adapts to the harsh marine environment and guarantees the safety of ship navigation and offshore operations.

Be the first to review “Triconex 4000212-010 Digital Input (DI) Module” Cancel reply

Reviews

There are no reviews yet.