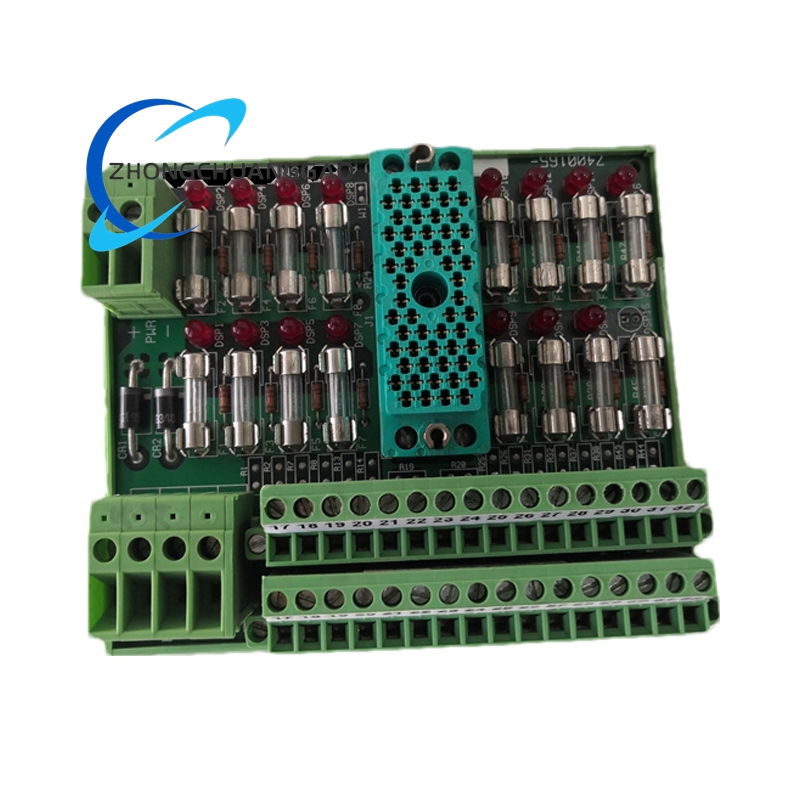

Product Short Description

Technical Specifications

- Electrical Parameters

- Input Channels: It is equipped with 48 independent digital input channels, which can collect signals from multiple on – site sensors and actuators at the same time to meet the high – density signal acquisition needs of large – scale industrial equipment.

- Voltage Range: It supports an input voltage range of 24 VDC to 55 VDC, which is compatible with most industrial low – voltage digital signal sources and has strong adaptability.

- Power Consumption: The maximum power consumption during operation is less than 2.5 watts, which has the advantage of low energy consumption and reduces the heat generation pressure of the control cabinet.

- Isolation Performance: It adopts photoelectric isolation technology for input signals, which can effectively isolate external electromagnetic interference and prevent signal distortion or module damage caused by voltage fluctuations and interference.

Description

-

- Physical Parameters

- Dimensions: The overall size is 115 mm x 60 mm x 23 mm, and the compact structure allows it to be installed in control cabinets with limited space, improving the space utilization rate of the system.

- Net Weight: The weight is only 250 grams, which is lightweight and convenient for installation, disassembly and transportation without increasing the load of the installation rack.

- Protection Level: It reaches IP66/NEMA 4X protection level, which can resist the erosion of dust, rainwater and other external substances and adapt to harsh on – site installation environments.

- Environmental Parameters

- Operating Temperature: It can maintain stable performance in the temperature range of – 40°C to 70°C, adapting to extreme temperature conditions such as cold outdoor industrial sites and high – temperature workshops.

- Storage Temperature: It can be safely stored in an environment of – 55°C to 85°C, ensuring that its performance will not be degraded during long – term storage or long – distance transportation.

- Humidity Adaptability: It can work normally in an environment with a relative humidity of 5% – 95% without condensation, which is suitable for humid industrial scenarios such as coastal petrochemical plants and water treatment plants.

- Physical Parameters

- Functional Features

- High – Density Channel Design Improves Efficiency: With 48 digital input channels, the module achieves high – density signal acquisition. This design reduces the number of modules required for large – scale industrial systems, simplifies the overall structure of the control cabinet, lowers the system configuration cost, and also reduces the difficulty of on – site wiring and later management.

- Triple Modular Redundancy Ensures Fault Tolerance: It adopts a triple modular redundancy architecture. Three independent circuits simultaneously collect and verify each channel’s signal, and the final signal output is determined through a majority voting mechanism. Even if one or two circuits fail, the module can still output accurate signals, completely avoiding system failures caused by single – point faults.

- Programmable Filter and Photoelectric Isolation Reduce Interference: The module is equipped with a programmable filtering function that can be adjusted according to the on – site signal environment to filter out invalid interference signals and ensure the accuracy of signal collection. At the same time, the photoelectric isolation design isolates the internal circuit of the module from external signal sources, preventing electromagnetic interference and voltage surges from affecting the module’s operation.

- Comprehensive Diagnostic Function Facilitates Maintenance: It has built – in full – range diagnostic capabilities that continuously monitor the operating status of each input channel and the module itself. When faults such as poor wiring, abnormal input voltage or channel failure occur, the module will immediately send fault information to the upper – level system. This allows maintenance personnel to quickly locate the fault point and shorten the maintenance cycle.

- Hot – Swap Support Ensures Continuous Production: It supports hot – swap operations in the Triconex safety instrumented system. When a module needs to be replaced due to a fault, it can be done without shutting down the entire system. This feature ensures the continuous operation of the production line and minimizes economic losses caused by system downtime.

- Cybersecurity Certification Secures Data Transmission: It has obtained Achilles Level 1 cybersecurity certification. The multi – layer security design prevents unauthorized access to the module and malicious tampering of data during signal transmission, ensuring the integrity and confidentiality of data in the industrial control process.

- Application Scenarios

- Petrochemical Industry: It is widely used in the safety interlock systems of chemical reactors, distillation towers and storage tanks. It collects signals from liquid level switches, temperature sensors and pressure sensors on the equipment. When parameters such as material level and temperature exceed the safe threshold, it quickly transmits signals to trigger the shutdown of the feeding system or the start of pressure relief equipment, preventing chemical leakage and explosion accidents.

- Oil and Gas Industry: It is applied to emergency shutdown systems and fire and gas systems of onshore and offshore drilling platforms. It collects signals from gas concentration detectors and pipeline emergency stop buttons. When dangerous situations such as gas leakage occur, it promptly sends signals to the controller to initiate emergency shutdown procedures and protect the safety of personnel and equipment.

- Power Industry: It is integrated into the safety control systems of thermal power plants and nuclear power plant auxiliary equipment. It collects status signals from steam turbine sensors, boiler safety valves and other key equipment. When abnormal operation occurs, it feeds back information in a timely manner to help the system adjust parameters or shut down the unit, avoiding damage to power generation equipment and large – scale power outages.

- Manufacturing Industry: It is used in the automated production lines of automobile manufacturing and heavy machinery production. It collects signals from limit switches and equipment interlock devices on the production line. It ensures that each production process is carried out in accordance with preset procedures and prevents safety accidents caused by equipment misoperation.

- Rail Transit Field: It is applied to the safety monitoring systems of rail transit equipment such as train traction systems and signal control systems. It collects status signals from key components such as traction motor sensors and track circuit switches. It ensures the stable operation of the rail transit system and provides guarantee for the safety of train operation.

Be the first to review “Triconex 4000206-520 48-Point Triple Modular Redundancy Digital Input Module” Cancel reply

Reviews

There are no reviews yet.