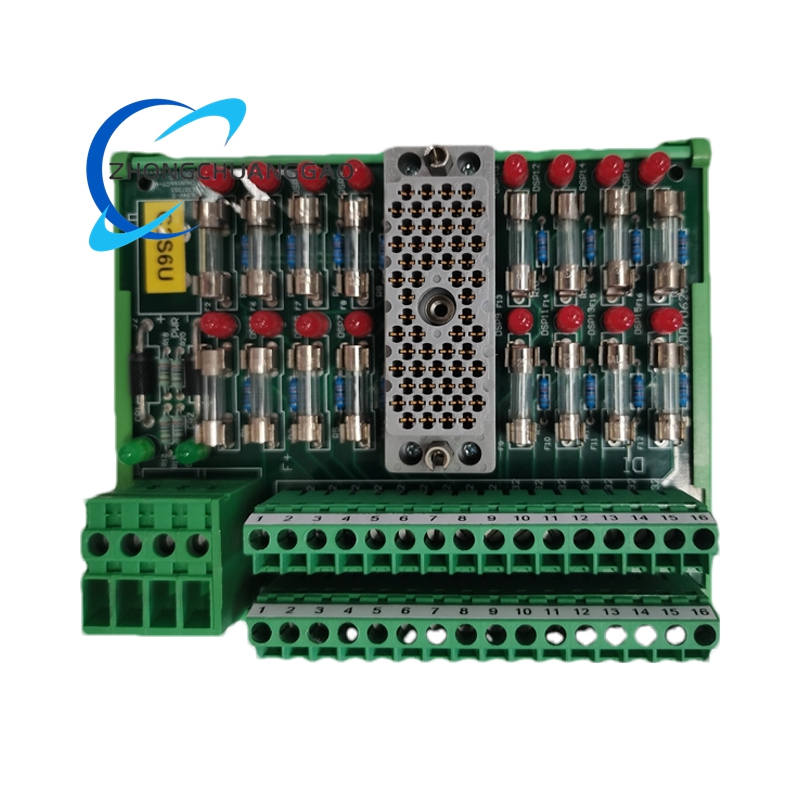

Product Short Description

Technical Specifications

- Power Parameters

- Nominal Voltage: It operates on a 24V DC nominal power supply, with an allowable voltage range of 19.2V DC to 30V DC and tolerates up to 5% AC ripple in the power input, which is fully compatible with the power supply systems of most industrial control cabinets.

- Power Interruption Tolerance: It can withstand a maximum power interruption of 1ms, preventing communication interruptions caused by transient power fluctuations on industrial sites.

- Communication Parameters

- Interface Configuration: It is equipped with 3 configurable RS – 232/RS – 485 serial ports and 2 10/100Base – T Ethernet ports. The serial ports support a maximum transmission rate of 115kbps per port, and the Ethernet ports achieve transmission rates of 10Mbps or 100Mbps as needed.

- Supported Protocols: It supports multiple industrial standard protocols. Serial ports work with Modbus Master (RTU) and Modbus Slave (ASCII/RTU). Ethernet ports are compatible with Modbus TCP/IP, TriStation, Peer – to – Peer (UDP/IP), TSAA and SNTP protocols, enabling connection with various industrial devices and systems.

Description

-

- Environmental Parameters

- Temperature Range: It can operate stably within the temperature range of – 40°C to 70°C and adapt to the extreme temperature changes of both indoor control rooms and outdoor industrial sites.

- Humidity Adaptability: It functions normally in an environment with a relative humidity of 5% to 95% under non – condensing conditions, which is suitable for humid working environments such as offshore platforms and chemical workshops.

- Environmental Parameters

- Functional Features

- Redundant Configuration Ensures Uninterrupted Communication: It supports 1 + 1 redundant configuration. When the main communication module malfunctions, the standby module will automatically take over the communication task without manual intervention. This design guarantees continuous communication links, which is essential for the normal operation of emergency shutdown systems and fire – gas detection systems.

- Rich Interfaces Meet Diverse Connection Needs: The combination of 3 configurable serial ports and 2 Ethernet ports allows the module to connect with different types of external devices simultaneously. It can link with field sensors and actuators through serial ports, and realize data interaction with upper – level distributed control systems and human – machine interfaces via Ethernet ports.

- Multi – Protocol Support Realizes Seamless Integration: Its compatibility with a variety of mainstream industrial communication protocols enables it to integrate smoothly with non – Triconex devices and systems. It can communicate with conventional Modbus – based industrial instruments and also connect with Triconex – specific programming and diagnostic tools through the TriStation protocol, reducing system integration complexity.

- Industrial – Grade Durability Adapts to Harsh Environments: The module adopts a rugged industrial – grade structural design. It can resist electromagnetic interference and voltage fluctuations common in industrial sites, and its stable performance will not be affected by dust, humidity and other harsh environmental factors, ensuring long – term reliable operation without frequent maintenance.

- Application Scenarios

- Oil and Gas Industry: It is deployed on offshore drilling platforms and onshore gas processing plants. It connects the Trident safety instrument system with pressure sensors, gas detectors and emergency shutdown valves. It transmits real – time data of equipment and environmental parameters, and ensures that the emergency shutdown system can receive control signals in a timely manner when dangerous situations such as gas leakage occur.

- Chemical Industry: It is integrated into the communication network of chemical reactor control systems. It exchanges data between the safety instrument system and temperature, pressure control modules of reactors. When reaction parameters exceed the safe range, it quickly transmits alarm information and receives adjustment instructions to avoid accidents such as reactor explosions.

- Power Generation Industry: It is used in the auxiliary control systems of thermal power plants and nuclear power plant auxiliary facilities. In thermal power plant boiler management systems, it connects the safety system with combustion control equipment. In nuclear power plant auxiliary systems, it ensures the stable transmission of data in coolant circulation monitoring links, safeguarding the safe operation of power generation equipment.

- Metallurgical Industry: It is applied to the communication links of steelmaking blast furnace control systems. It transmits data between the safety instrument system and blast furnace temperature, air pressure detection devices. It helps the control system adjust the air supply and feeding speed in real time and prevents equipment damage caused by abnormal parameters during the smelting process.

Be the first to review “Triconex 4000187-320 Trident Series Communication Module” Cancel reply

Reviews

There are no reviews yet.