Product Short Description

- Technical Specifications

- Electrical Parameters

The nominal power supply voltage is 24VDC, with an input voltage range of 0 – 30VDC. The maximum power consumption of the module is 10W. It has an input frequency range of 0 – 20kHz, which allows it to handle different frequency signals from field equipment and meet various signal collection needs.

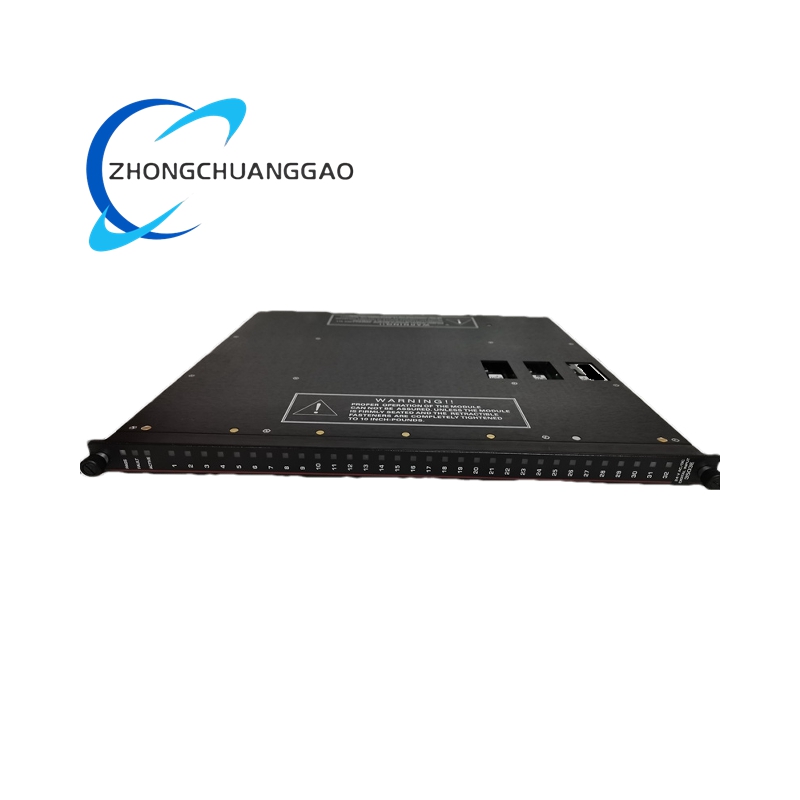

- Physical Parameters

The module has dimensions of 49×45.3×6.8cm and a weight of 4.8kg, making it easy to install and disassemble during on-site maintenance. Its compact size also helps save space in the control cabinet, facilitating reasonable layout with other modules.

- Environmental and Compliance Parameters

It is suitable for normal-temperature industrial environments and can maintain stable performance in common harsh industrial site conditions. It complies with relevant industry norms and holds CE, UL, and CSA certifications, which confirms its compliance with strict quality and safety standards for smooth application in different regional industrial projects.

- Electrical Parameters

Description

- Functional Features

- Triple Modular Redundancy for Fault Tolerance

It adopts triple modular redundancy technology. Each input point is processed by three independent and identical input channels, and a hardware voting mechanism is used to verify the correctness of input signals. This design eliminates the impact of single or double channel faults on the system, ensuring the accuracy and reliability of signal acquisition and preventing safety accidents caused by wrong signals.

- Stable Signal Acquisition and Transmission

It has a stable input circuit design and can stably receive digital signals from various field devices. It minimizes signal distortion during transmission and ensures that the upper control system can obtain real and effective field device status information. Its fixed input frequency and voltage ranges further guarantee the stability of signal acquisition, avoiding signal misreading due to voltage or frequency fluctuations.

- Seamless Integration with Multiple Systems

It can achieve seamless connection with distributed control systems and other upper computers, enabling efficient data interaction between the module and the upper control platform. It uses Triconex’s proprietary communication protocol to ensure smooth information transmission and realize integrated and automated control of the entire industrial system without compatibility issues affecting the overall operation efficiency.

- Convenient Installation and Maintenance

It has a lightweight and compact structure, which reduces the difficulty of on-site installation and later maintenance. The modular design is consistent with the overall style of Triconex series products, allowing it to be quickly mounted on the corresponding baseplate of the control system. The simple structure also makes it easy for maintenance personnel to check and troubleshoot, reducing maintenance time and costs.

- Triple Modular Redundancy for Fault Tolerance

- Application Scenarios

- Oil and Gas Industry

It is widely used in oil drilling platforms, natural gas transmission stations and refineries. It collects digital signals from emergency stop buttons, pressure switches and flame detectors on site. It provides key input information for emergency shutdown systems and fire and gas detection systems, ensuring the safety of oil and gas extraction, transmission and refining processes.

- Chemical Industry

In chemical production plants, it is applied to monitor the status of on-site equipment such as valve positions, interlock switches and level switches. It promptly feeds back abnormal signals of equipment in chemical batching, reaction and other processes to the control system, preventing safety accidents caused by equipment failure and ensuring the safe and orderly progress of the entire chemical production process.

- Power Generation Industry

It is installed in thermal power and nuclear power plants to receive signals from protective relays and trip contacts of generating units. It transmits the operating status signals of key equipment such as boilers and turbines to the safety monitoring system. It provides reliable data support for the safety protection of power generation equipment and ensures the stable operation of the power grid and the safe production of power plants.

- Marine and Offshore Engineering

It is used in offshore oil and gas exploitation platforms and other marine engineering equipment. It collects signals from various marine – specific safety switches and monitoring sensors. It can adapt to the special marine environment and maintain stable operation, ensuring the safety of offshore operation personnel and equipment and the smooth progress of exploitation operations.

- Oil and Gas Industry

Reviews

There are no reviews yet.