Product Short Description

- Technical Specifications

- Environmental Adaptability

It has an operating temperature range of -40°C to 75°C and a storage temperature range consistent with this range, adapting to extreme temperature fluctuations in industrial sites. It operates stably in an environment with a relative humidity of 5% – 95% non – condensing, and can resist the impact of moist air in workshops and outdoor control cabinets without affecting signal transmission quality.

- Physical Specifications

It adopts a compact design that matches the installation dimensions of standard Triconex I/O racks. The lightweight structure allows it to be installed smoothly in the rack without adding excessive load to the overall system. The standardized mounting holes align with Triconex’s unified installation standards, facilitating quick assembly with other modules.

- Electrical Performance

It has a port isolation voltage of 500 VDC, which can effectively isolate electrical interference between different signal channels and prevent mutual interference between strong and weak currents. It supports low – power operation, and its power consumption is integrated into the overall power consumption system of the I/O rack, which will not increase the burden of the system’s power supply unit.

- System Compatibility

It achieves seamless compatibility with Triconex core systems including Tricon and Tricon CX. It can perfectly match various I/O modules of the Triconex series, and can also cooperate with the TriStation software suite to complete system configuration, debugging and fault diagnosis.

- Environmental Adaptability

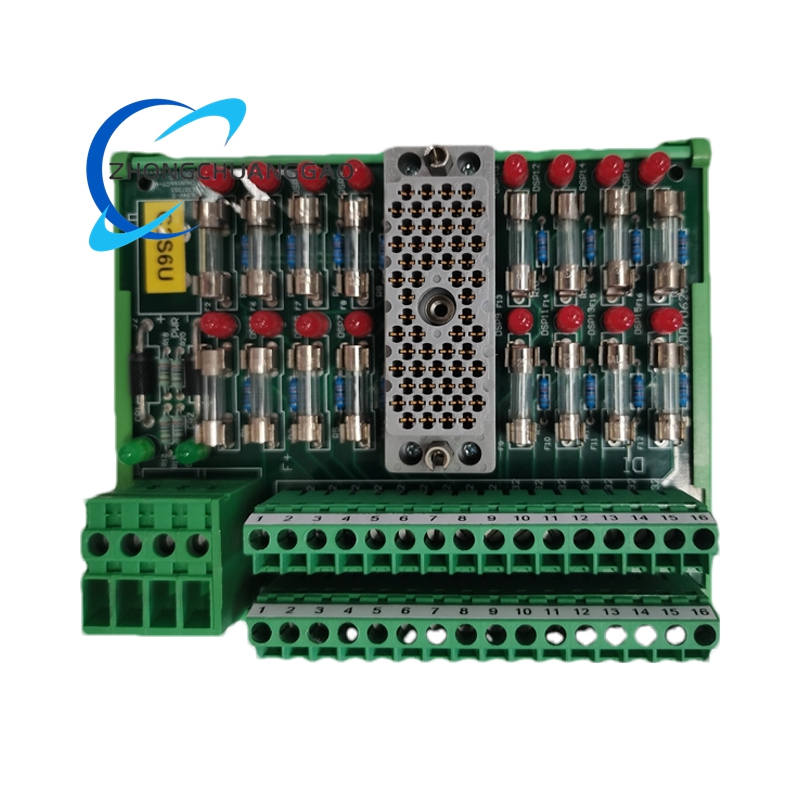

Description

- Functional Features

- Stable Signal Transmission

It serves as a bridge for signal transmission between I/O modules and the main controller. It optimizes the signal transmission path and reduces signal attenuation and delay. It ensures that the analog and digital signals collected by the on – site sensors can be accurately and quickly transmitted to the main control unit, and the control commands issued by the main control unit can be efficiently delivered to the actuators.

- Integrated Fault Isolation

The independent channel design realizes fault isolation between different I/O signal paths. When a certain signal channel fails, the fault will not spread to other channels. The component can cooperate with the system’s diagnostic function to quickly locate the faulty channel, which helps maintenance personnel to carry out targeted repairs.

- Seamless System Integration

It follows Triconex’s unified system architecture and communication protocols. It can be directly integrated into the existing Triconex safety control system without complex adaptation transformation. It supports the expansion of the system’s I/O capacity, and can be added to the system synchronously when the number of on – site devices increases, realizing flexible expansion of the system.

- Simplified Maintenance Operations

It has clear and intuitive status indicators. Maintenance personnel can directly observe the working status of the component through the indicators to quickly determine whether it is in normal operation. The modular disassembly design allows for quick removal and replacement without stopping the entire system, minimizing maintenance downtime.

- Stable Signal Transmission

- Application Scenarios

- Petrochemical Industry

It is installed in the Triconex safety interlock system of petrochemical refining and chemical plants. It connects the I/O modules of reaction kettles, distillation towers and pipeline equipment. It transmits signals of temperature, pressure and liquid level between the on – site detection equipment and the emergency shutdown system. It ensures that the system can immediately trigger the shutdown procedure when dangerous conditions such as excessive pressure occur.

- Power Generation Industry

In nuclear power and thermal power plants, it is applied to the Triconex control system of key equipment such as boilers and steam turbines. It connects the I/O modules of water level sensors, steam pressure detectors and speed monitors. It guarantees the stable transmission of equipment operation signals. It helps the system adjust parameters in a timely manner and implement protective measures when abnormalities are found, ensuring the safe operation of power generation units.

- Natural Gas Industry

It is deployed in natural gas long – distance transmission pipelines and terminal processing stations. It is integrated into the Triconex gas leakage monitoring and emergency control system. It connects the I/O modules of gas concentration sensors and pipeline valve actuators. It ensures the real – time transmission of leakage signals and control commands, and realizes the rapid closing of valves when gas leakage occurs to avoid explosion accidents.

- Chemical Industry

In chemical production workshops involving flammable, explosive and corrosive raw materials, it is used in the Triconex process control system. It connects the I/O modules of material level sensors, reaction rate detectors and other equipment. It maintains the smooth transmission of process control signals. It assists the system in accurately adjusting production parameters, prevents abnormal reactions, and protects the safety of production equipment and personnel.

- Petrochemical Industry

Reviews

There are no reviews yet.