Product Short Description

Technical Specifications

- Physical Parameters

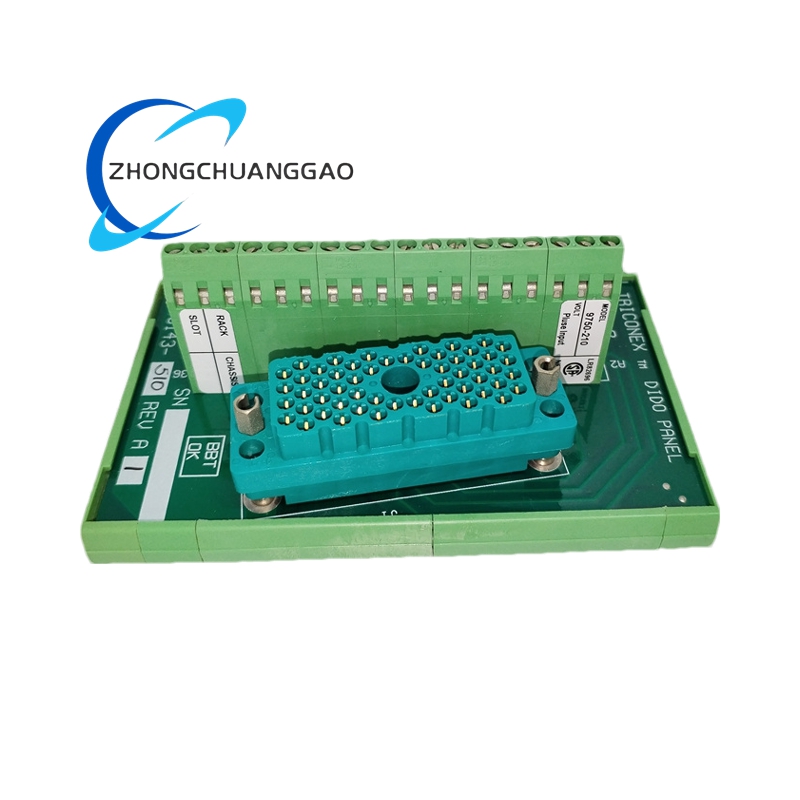

Its dimensions measure 15.7 centimeters by 12.3 centimeters by 7.6 centimeters, and it weighs 7.00 pounds. The compact size allows it to fit into the standardized installation positions of the Tricon system without occupying excessive space, facilitating flexible deployment in various cabinet layouts.

- Compatibility

It is fully compatible with the Tricon series safety systems. It supports various types of terminator modules, which meets the diverse connection requirements of different external terminators in the system. It also achieves seamless integration with a wide range of field devices such as industrial sensors and actuators, adapting to different industrial control scenarios.

- Safety Certification

It is part of the Triconex Tricon safety system ecosystem, and the entire system it belongs to has obtained TÜV Rheinland certification. It complies with the IEC 61508 international standard and meets the requirements of Safety Integrity Level 3. It also meets the standards for 1E – class nuclear energy applications, which fully satisfies the strict safety requirements of high – risk industrial fields.

Description

-

- Installation Compatibility

It adopts a design that allows for easy installation. It matches the mounting dimensions and interface standards of the Tricon system rack. It can be quickly installed and fixed without the need for customized installation accessories, which is in line with the modular assembly specifications of the Tricone series of products.

- Installation Compatibility

- Functional Features

- Seamless System and Device Integration

It provides a standardized connection interface that enables seamless integration of field devices like sensors and actuators into the Tricon safety system. It eliminates compatibility issues between different devices and the system, ensuring that data and control signals can be transmitted smoothly between field equipment and the upper – level safety system.

- Stable Connection for Reliable Signal Transmission

It is structurally designed to offer secure mounting and connection points for external terminators. It avoids signal transmission interruptions or distortions caused by loose connections due to factors such as vibration in industrial environments. It ensures the stability and integrity of signal transmission between external terminators and the Tricon system.

- Broad Terminator Module Support

It supports a variety of terminator modules. It does not limit the use of a single type of external terminator and can adapt to different signal types and transmission requirements. This flexibility reduces the difficulty of system configuration and lowers the cost of equipment replacement and upgrade.

- Simplified Installation and Reduced Maintenance Costs

Its user – friendly installation design simplifies the on – site assembly process. Installation personnel can complete the installation quickly without complex professional operations. This design minimizes the system downtime during installation and maintenance. At the same time, its stable structural performance reduces the frequency of failures, thereby cutting down long – term maintenance costs for enterprises.

- Seamless System and Device Integration

- Application Scenarios

- Oil and Gas Industry

It is applied in upstream oilfield exploitation, midstream pipeline transportation, and downstream refining processes. It connects field devices such as pressure sensors and flow meters on oil and gas pipelines with the Tricon safety system. It ensures the reliable transmission of data related to oil and gas pressure and flow. It provides data support for emergency shutdown systems and high – integrity pressure protection systems, preventing accidents such as pipeline leaks and overpressure.

- Chemical Industry

In chemical production workshops, it is used in the safety control systems of reaction kettles, storage tanks, and other key equipment. It connects temperature, concentration, and other sensors with the Tricon system. It realizes real – time monitoring of chemical reaction process parameters. Once abnormal parameters are detected, the system can send out control signals in a timely manner to avoid dangerous situations such as explosions and leaks caused by abnormal chemical reactions.

- Power Generation Industry

It is integrated into the safety systems of thermal power, nuclear power, and other power plants. In nuclear power plants, it meets the 1E – class nuclear energy application standards and connects monitoring devices of nuclear reaction – related equipment with the safety system. In thermal power plants, it links sensors for boiler steam pressure and turbine speed to the control system. It ensures the safe and stable operation of power generation equipment and avoids large – scale power outages caused by equipment failures.

- Pharmaceutical Industry

It is used in precision production processes such as drug fermentation and purification. It connects sensors that monitor parameters like temperature, pH value, and stirring speed in the production equipment with the Tricon safety system. It ensures that all parameters in the drug production process are within the preset range, which guarantees the stability and qualification rate of drug quality.

- General High – risk Industrial Fields

It is also suitable for other high – risk industrial fields equipped with Tricon safety systems, such as coal chemical industry and mining. It provides reliable connection and signal transmission support for the safety monitoring and control of key production equipment. It helps enterprises meet strict industrial safety supervision requirements and reduces the probability of safety accidents.

- Oil and Gas Industry

Reviews

There are no reviews yet.