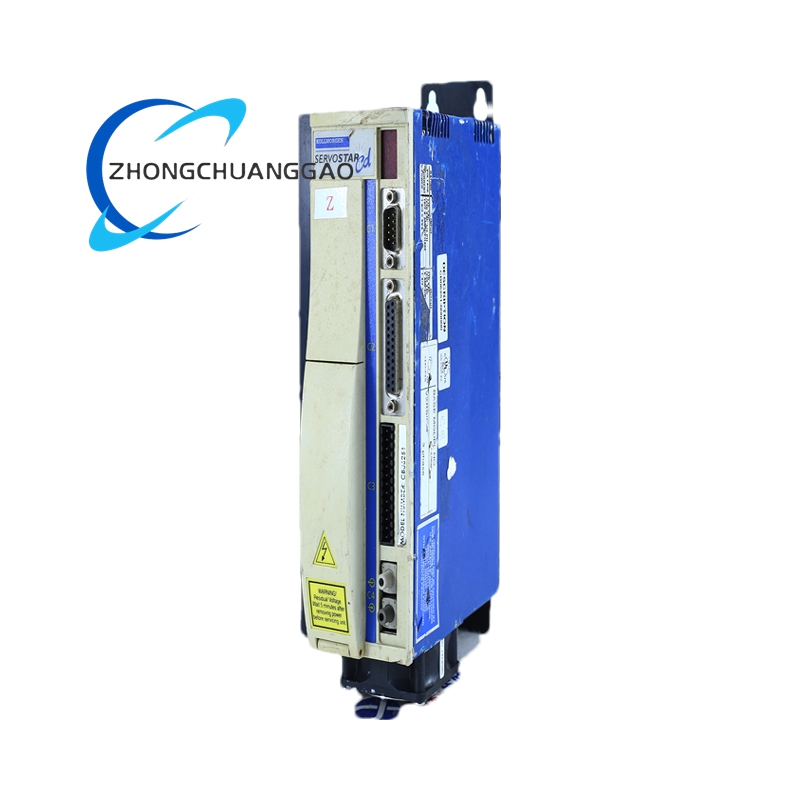

Product Short Description

-

Technical Specifications

- Electrical Parameters

- Input Voltage: It supports a single-phase AC input voltage range of 115V to 230V, adapting to different regional power supply standards and facilitating flexible deployment in various industrial sites.

- Current and Power Ratings: It has an input current specification of 10/7.8 amps and a power rating of 1.8/2.8 kVA, which can provide sufficient power output to drive matching servo motors and meet the power demands of medium-load motion control tasks.

- Output Frequency: It operates at an output frequency of 30 kHz, which ensures rapid response and precise regulation during motor operation and meets the requirements of high-speed motion control scenarios.

- Physical Parameters

- Structural Design: It adopts a compact eurocard – compatible structural design that conforms to industrial standard installation specifications. The compact size enables it to be easily installed and arranged in dense control cabinet layouts without occupying excessive space.

- Installation Method: It fits standard industrial mounting rails, allowing for quick assembly and disassembly, which simplifies the installation and maintenance processes.

- Functional Related Parameters

- Motor Compatibility: It is fully compatible with brushless DC motors and stepper motors, establishing stable and reliable drive connections with these motors to exert optimal motion control performance.

- Control Resolution: It integrates advanced digital control technology, which ensures high control resolution in torque, speed, and position control, minimizing errors in motor operation.

- Electrical Parameters

Description

-

Function Features

- High-Precision Motion Control: The drive adopts advanced control algorithms and digital control technology to achieve precise regulation of servo motor position, speed, and torque. It maintains consistent motion accuracy during high-speed and low-speed operation, which effectively reduces motion errors of industrial equipment and improves the processing and production quality of products.

- Broad Compatibility: It has good compatibility with multiple types of motors including brushless DC motors and stepper motors. It also supports seamless integration with various industrial automation systems, which eliminates compatibility issues during system configuration and reduces the difficulty of equipment transformation and upgrading.

- Compact and Space-Saving Design: Its compact structural design optimizes the use of space in control cabinets. It can be easily installed even in environments with dense layout of electrical components, which expands its applicability in small – sized automation equipment and compact production lines.

- Built-In Comprehensive Protection Functions: It is equipped with complete protection mechanisms that cover overcurrent, overvoltage, and overload protection. These functions quickly cut off relevant circuits when abnormal electrical conditions occur, preventing damage to the servo drive itself, the connected servo motor, and other related components.

- User-Friendly Deployment: It is designed with a user-friendly interface and multiple input/output options. It allows for simple parameter setting and debugging, which shortens the commissioning cycle of the entire equipment. Its standardized wiring interfaces also reduce wiring errors and improve the efficiency of on-site installation and maintenance.

-

Application Scenarios

- Robotics: It serves as a joint driver for industrial robots and robotic arms. It precisely controls the rotation angle and movement speed of each joint of the robot, which ensures the accuracy of actions such as grabbing, welding, and assembling of the robot. It is widely used in automated production workshops such as automobile assembly and electronic component processing.

- Numerical Control Machinery: It is applied to numerical control milling machines, lathes, cutting machines, and grinders. It controls the feed motion and spindle rotation of the equipment with high precision, which guarantees the dimensional accuracy and surface finish of processed workpieces and improves the processing efficiency and product qualification rate of the equipment.

- Packaging Machinery: It is integrated into automated packaging production lines for food, beverages, and daily chemicals. It controls the movement of filling machines, capping machines, and labeling machines. It realizes precise synchronization of each process on the packaging line, which ensures consistent packaging specifications and avoids problems such as leakage and incorrect labeling.

- Medical Equipment: It is used in medical devices that require precise motion control, such as medical imaging equipment and precision surgical auxiliary equipment. It provides stable and accurate motion drive for relevant components of the equipment, which helps improve the accuracy of medical diagnosis and the safety of surgical operations.

- Textile Machinery: It is deployed in textile equipment such as looms and winding machines. It accurately controls the speed of yarn feeding and fabric winding, which maintains the tension stability of textiles during the production process. It prevents problems such as yarn breakage and uneven fabric density, and ensures the quality of textile products.

Be the first to review “Kollmorgen CB06251 High-Performance Servo Drive” Cancel reply

Reviews

There are no reviews yet.