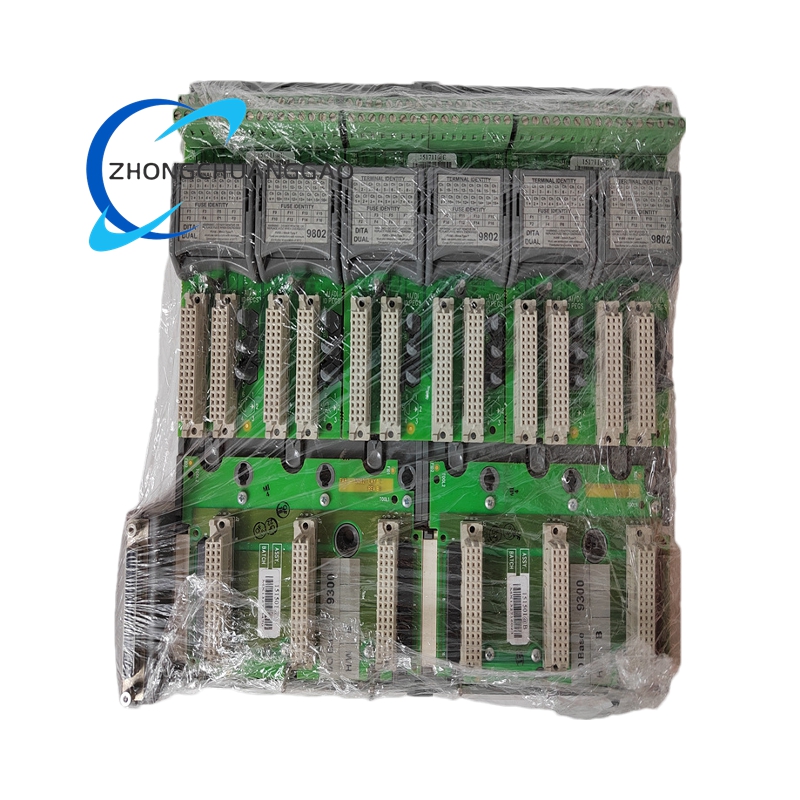

Product Short Description

Technical Specifications

- Electrical Parameters

- Power and Current: The maximum power dissipation of each field loop is 0.2 watts. Each input channel is configured with 50mA, 125V type T fuses. The module has a maximum current consumption limit per channel, and the overall maximum power consumption can reach 1.5 watts.

- Isolation and Signal Resolution: The maximum withstand voltage of channel isolation is ±1.5 kVdc for 1 minute. The input measurement voltage resolution is 5 mV with a 13-bit precision, and each channel has a load of 5.125±0.2% kΩ, which can minimize the load on input devices.

- Communication and Protocol: It is equipped with an RS – 485 communication interface and supports communication protocols such as Modbus TCP/IP and Modbus RTU, which facilitates seamless data exchange with existing industrial networks.

- Physical Parameters

- Dimensions and Conductor: The conductor cross-section can reach a maximum of 1.31 mm², and the required wire stripping length is 6 mm for wiring. It adopts a modular and compact structure that fits standard industrial installation racks.

- Weight: The standard weight of the module is 1256 grams, and some versions weigh around 1.5 kilograms, which is easy to install and disassemble without causing excessive load on the installation structure.

Description

-

- Environmental Parameters

- Temperature Range: The operating temperature range is -20°C to 60°C, and the storage temperature range extends from -40°C to 85°C, enabling it to adapt to extreme temperature conditions during transportation and field operation.

- Humidity Tolerance: It can operate normally in an environment with 0% – 95% relative humidity without condensation, which is applicable to humid industrial sites such as water treatment plants and coastal industrial zones.

- Environmental Parameters

-

Function Features

- Reliable Channel Protection Mechanism: Each input channel is equipped with 50mA fuses that can quickly cut off the circuit when encountering current overload or short-circuit faults. This prevents damage to the module and connected field devices, effectively extending the service life of the entire control system.

- Strong Anti-interference Through Dual Isolation: The module is designed with dual isolation technology and has a high isolation voltage. It can resist voltage surges and transient interference in industrial environments, avoid signal distortion caused by external electrical interference, and ensure the accuracy and stability of digital signal acquisition and transmission.

- Flexible Compatibility and Configuration: It is compatible with specific input modules and adopts a modular architecture. The 16 programmable channels can handle a variety of digital input signals. Users can flexibly configure the module according to actual application requirements to meet different automation task needs.

- Easy Integration and Setup: It supports mainstream industrial communication protocols and interfaces. It can be seamlessly integrated into existing industrial control systems without complex programming work. The standardized connection method and intuitive configuration process greatly reduce the difficulty of system deployment and debugging.

- Precise Signal Processing: With 13-bit input measurement resolution and 5mV voltage resolution, the module can accurately capture tiny changes in digital signals. It also achieves automatic signal offset compensation to reduce measurement errors caused by environmental fluctuations and improve the reliability of data acquisition.

-

Application Scenarios

- Oil and Gas Industry: It is widely used in oil drilling platforms, refining plants and long-distance oil and gas pipeline control systems. It collects digital signals from pipeline pressure switches, gas leak sensors and valve position sensors. It transmits accurate signal data to the central controller to support timely execution of safety interlocking measures such as emergency shutdown when abnormal conditions occur.

- Power Generation Industry: It is applied to the control systems of thermal power, hydropower and other power plants. It is responsible for collecting digital signals from key equipment such as boilers and steam turbines, including switch states of auxiliary equipment and alarm signals of operating parameters. It provides reliable data support for the stable operation of power generation equipment and avoids unplanned power outages caused by equipment failures.

- Chemical Industry: It is integrated into the control systems of chemical reaction kettles, hazardous chemical storage tanks and mixing equipment. It collects on-site digital signals such as temperature switch signals and pressure interlock signals in chemical production processes. It ensures that the control system can quickly respond to process abnormalities and cut off dangerous links in a timely manner to prevent leakage of toxic and harmful substances and explosion accidents.

- Water Treatment Industry: It is used in urban sewage treatment plants and industrial wastewater treatment systems. It collects digital signals from liquid level switches, flow switches and sludge discharge equipment sensors in various treatment pools. It helps the central system monitor the operation status of the treatment process in real time and ensures the stability and compliance of the water treatment process.

Be the first to review “Ics Triplex T9802 AADvance Digital Input Termination Assembly” Cancel reply

Reviews

There are no reviews yet.