Product Short Description

- Technical Specifications

- Core Processing and Memory: It adopts the Motorola 68040 processor that excels in floating-point calculations and efficiently handles complex industrial control algorithms. It has a 16-megaword memory capacity, which is sufficient to support the operation of the TDC 3000 system’s R500 software and store a large amount of process data, control codes and system configuration information.

- Power and Communication: It obtains power through the TDC 3000 rack with a supply voltage of 5V DC. It is equipped with an LCN interface that enables smooth data transmission and communication with other modules and upper-level control units in the TDC 3000 system.

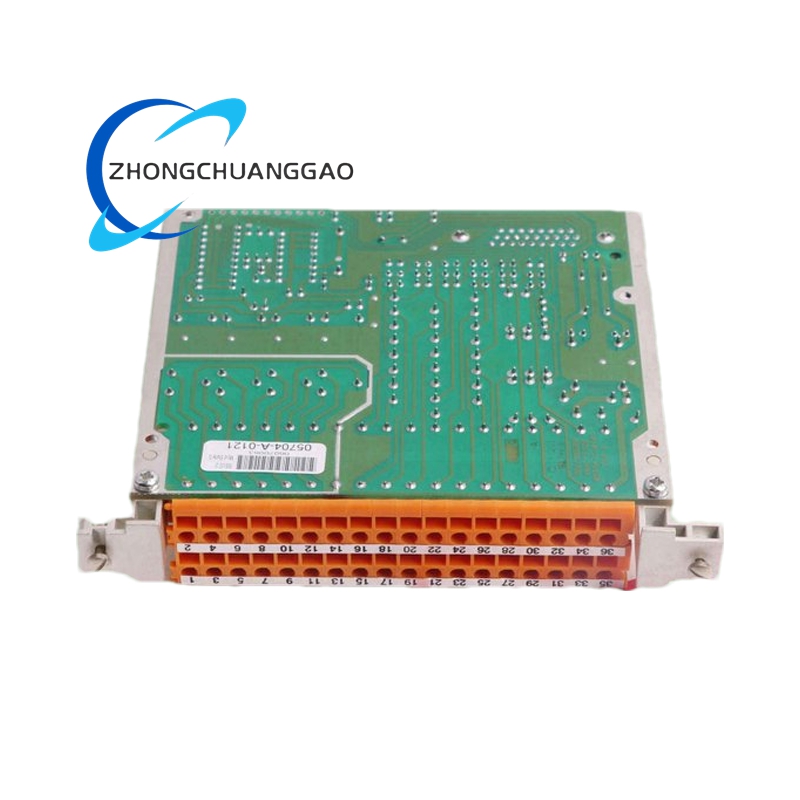

- Physical Parameters: It adopts a standard 5-slot module size, approximately 12.5 x 5.5 x 1.5 inches, and weighs about 1.2 kg. The protection level reaches IP20, which is suitable for installation inside indoor industrial control cabinets to prevent dust intrusion.

- Environmental and Certification Parameters: Its operating temperature ranges from 0°C to 60°C, and the storage temperature is from -40°C to 85°C. It can operate stably in a non-condensing humidity environment of 0% to 95% RH. It has obtained CE, UL and CSA certifications, fully complying with relevant industrial environment application standards.

Description

- Functional Features

- Powerful Data Processing Capability: The Motorola 68040 processor at its core provides strong computing power, which can quickly collect and process data from on-site sensors and equipment. It can also execute complex safety control algorithms and generate control commands in real time to ensure the timely response of the TDC 3000 system to changes in industrial processes.

- Seamless System Compatibility: It is fully compatible with all components of the Honeywell TDC 3000 system and can integrate perfectly with the system’s Local Control Network. It does not require complex adaptation adjustments during installation and operation, ensuring the overall stability and coordination of the control system.

- Field-Upgradable and Easy Maintenance: Its memory board supports on-site upgrade operations. Users can replace the memory sub-board to expand capacity or update related functions according to actual application needs. The modular design and standardized interface also simplify the installation and daily maintenance processes, reducing the difficulty and time cost of operation.

- High Safety and Durability: It meets strict industrial safety standards and is compliant with safety-related application requirements. The circuit boards are coated to enhance corrosion and wear resistance. This robust structural design extends the service life of the module and reduces maintenance frequency and costs in long-term industrial operations.

- Application Scenarios

- Petrochemical Industry: It is widely used in refineries and natural gas processing plants. It is deployed in the control systems of reaction kettles, distillation towers and other key equipment to process data such as temperature, pressure and material concentration in real time. It executes safety control logic to prevent safety hazards such as explosions and chemical leaks and ensures the stable progress of petrochemical production processes.

- Power Industry: In thermal power plants and nuclear power plants, it is integrated into the distributed control systems of generator sets. It is responsible for core computing tasks such as monitoring steam pressure, temperature and power load. It ensures the stable operation of generator sets and the safe transmission of electrical energy, and provides reliable support for the safe operation of the power grid.

- Chemical and Pharmaceutical Industry: In chemical and pharmaceutical production processes that require strict batch control, it processes process data in real time and precisely controls the feeding amount, reaction time and other parameters. It guarantees the consistency and qualification rate of product quality and meets the strict production standards of the two industries.

- General Manufacturing and Transportation: In the manufacturing industry, it is applied to mechanical protection systems on production lines to protect workers from machine damage by controlling the start and stop of equipment. In the transportation field, it is integrated into transportation safety control systems to participate in data processing and safety logic execution, and maintains the safety and stability of transportation operations.

Be the first to review “Honeywell K4LCN-16 51403519-160 High-Performance Memory Processor Module for TDC 3000 System” Cancel reply

-500x500.jpg)

Reviews

There are no reviews yet.