Product Short Description

Technical Specifications

- Communication Parameters

- It operates at a data transmission rate of 10 – 100 Mbaud, which meets the requirements of high-speed data interaction in industrial automation scenarios.

- It supports mainstream protocols such as Modbus and EtherNet/IP, and is equipped with RS – 232, RS – 485 and Ethernet interfaces, with an RJ45 LAN connector for easy connection to industrial local area networks.

- It can handle a maximum input data volume of 240 bytes and a maximum output data volume of 480 bytes, with a configuration data frame size of up to 480 bytes.

- It features LAN redundancy to ensure continuous communication even if a single network path fails.

- Electrical Parameters

- It is compatible with standard industrial power supply configurations and matches the 380V AC or 690V AC rated voltage commonly used in industrial power systems.

- It adopts low-power design, and the power consumption during operation is controlled within 15W, which reduces the energy loss of the entire control system.

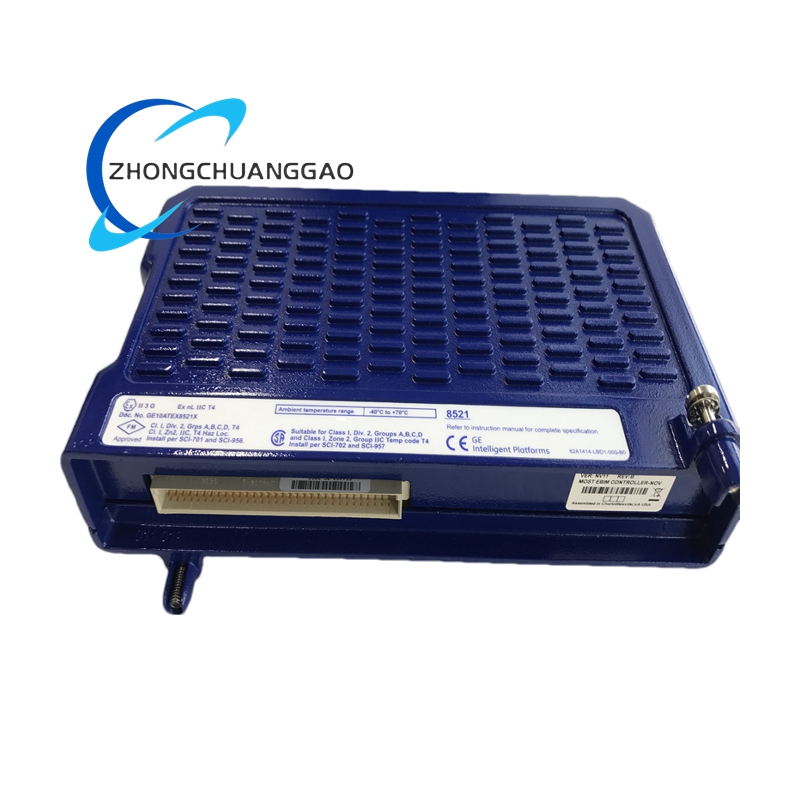

Description

- Environmental and Physical Parameters

- The operating temperature range is -20°C to 60°C, and the storage temperature range is -40°C to 85°C, adapting to temperature fluctuations in indoor control cabinets and outdoor industrial sites.

- It has a compact structure, with a standard industrial module size that fits DIN rail installation, facilitating assembly into various control cabinets and saving installation space.

- It uses industrial-grade metal casings, which have strong anti-vibration and anti-electromagnetic interference capabilities, ensuring that data transmission is not affected by the surrounding industrial equipment.

Function Features

- Dual Core of Communication and Protection

While completing high-speed data transmission, it integrates multiple equipment protection functions. It can monitor faults such as overcurrent, undercurrent, overvoltage, undervoltage, phase loss and single-phase grounding of power equipment. Once an abnormal condition is detected, it can quickly send out fault signals and trigger protective actions to prevent damage to transformers, lines and other key equipment.

- Stable and Reliable Redundant Design

It is designed with LAN redundancy, which can automatically switch to a standby communication path when the main communication link fails. This redundant design avoids communication interruptions caused by single-point failures, ensuring the continuous operation of the industrial control system and improving the stability of the entire communication network.

- Convenient Fault Diagnosis and Monitoring

It is equipped with LED indicators that can visually display the module’s power supply status, communication connection status and operating status. It can quickly feed back fault information to the upper-level control system. Maintenance personnel can locate problems such as communication failures or equipment abnormalities in a short time, reducing the difficulty and time of troubleshooting.

- Strong Adaptability with Modular Expansion

It adopts a modular design, which can be flexibly combined with different types of I/O modules. Users can increase or decrease the number of connected modules according to the scale of the project and functional requirements. It can be seamlessly integrated into existing PAC8000 series control systems without the need for large-scale modifications to the original system, enhancing the adaptability of the system to different application scenarios.

Application Scenarios

- Energy and Power Industry

It is widely used in thermal power plants, hydropower stations and transformer substations. It connects generators, transformers and power transmission line monitoring equipment. It transmits real-time data such as voltage and current of power equipment and realizes rapid protection when faults occur, ensuring the stable operation of the power grid and preventing large-scale power outages.

- Petrochemical and Chemical Fields

It is applied to chemical reaction kettles, oil pipelines and storage tank monitoring systems in petrochemical plants. It connects sensors and actuators on site, transmits process parameters such as temperature and pressure during production, and protects the power supply and transmission equipment of key production links, avoiding production accidents caused by equipment failures.

- Metallurgy and Mining Industry

It is used in steelmaking blast furnaces, aluminum smelting equipment and mining machinery. It coordinates the communication between the central control system and crushing equipment, conveyor belts and smelting equipment. It monitors the operating status of high-power motors in the equipment and triggers overload and over-temperature protection in a timely manner, ensuring the safety of metallurgical and mining production processes.

- Transportation and Marine Fields

It is integrated into railway power supply systems and marine power control systems. In railway transportation, it protects the power equipment of signal systems and traction locomotives. On ships, it connects various marine power equipment and realizes data transmission and fault protection between the ship’s central control room and terminal equipment, adapting to the special marine environment and ensuring navigation safety.

- Water Treatment and Building Automation

It is used in urban water supply and sewage treatment plants to connect water pumps, dosing equipment and water quality sensors. It ensures the stable operation of water treatment processes through real-time communication and equipment protection. In large buildings, it is integrated into the power control system of central air conditioning and elevator equipment, realizing the monitoring and protection of building power equipment and improving the reliability of building automation systems.

Reviews

There are no reviews yet.