Product Short Description

Technical Specifications

- Electrical Parameters

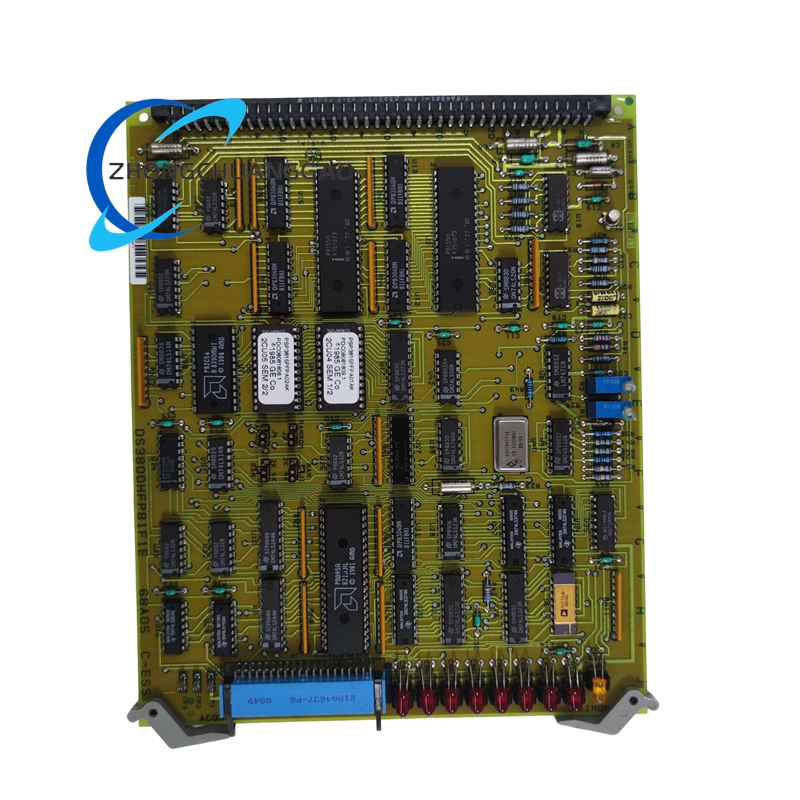

- It specializes in processing 4 – 20mA analog input and output signals, which are used to transmit key data such as compressor stall detection signals and fuel flow pressure signals.

- It supports +/- 10VDC voltage input signals, which can adapt to the signal output requirements of vibration sensors and other equipment.

- It provides signal support for thermocouple inputs and realizes cold – end compensation for thermocouple signals through matching terminal board connectors, ensuring the accuracy of temperature signal collection.

- Hardware and Connection Parameters

- It is equipped with multiple hardware jumpers for functional configuration. Specific jumpers are used to select milliamps output circuits, and some jumpers can configure the milliamps output current range to 20mA or 200mA as required. There is also a dedicated jumper for card testing via the RS232 port and another for starting the oscillator.

- It is configured with multiple functional connectors. The 3PL connector serves as a data bus to connect with multiple boards in the core and transmits conditioned signals to the COREBUS. The JE connector realizes the transmission of pulse signals, generator and line signals with another board, while the JF connector receives LVDT/LVDR position input signals.

Description

- Physical and Environmental Parameters

- It adopts a standard circuit board structure that fits the slot size of the Mark V series control system, facilitating installation on the I/O cores of the system without additional modification.

- It operates stably within an ambient temperature range of -30°C to 55°C, which can adapt to the temperature changes in turbine rooms and industrial workshops.

- It has anti – electromagnetic interference design, which can resist the electromagnetic interference generated by high – power equipment around the gas turbine and ensure the stability of signal transmission.

Function Features

- Multi – type Signal Scaling and Conditioning

The board can handle a diverse range of analog signals involved in gas turbine operation. It scales and conditions not only conventional 4 – 20mA signals and +/- 10VDC signals but also special signals such as thermocouple inputs and vibration inputs. This process filters out noise and interference in the signals, converts them into standardized signals that can be recognized and processed by the system, and lays a foundation for the accurate control of gas turbines.

- Flexible Functional Configuration via Jumpers

The hardware jumpers on the board provide flexible configuration options for different application requirements. Operators can set jumpers to adjust the output current range, initiate board testing, or activate the oscillator. This flexibility enables the board to adapt to different signal processing needs of gas turbines under various operating conditions without replacing the entire board.

- Efficient Multi – path Signal Routing

With multiple dedicated connectors, the board establishes stable connection channels between different functional boards and the system bus. It classifies and transmits various processed signals to corresponding target boards through specific connectors, ensuring orderly and efficient data transmission between subsystems of the gas turbine control system and avoiding signal confusion or transmission delays.

- Targeted Fault Prevention for Key Signals

For critical signals such as compressor stall detection and fuel flow pressure, the board conducts targeted conditioning and transmission. By optimizing the signal quality of these parameters closely related to the safe operation of gas turbines, it helps the upper – level control system promptly capture abnormal data. This timely feedback prevents potential risks such as compressor stalls or unstable fuel supply, effectively improving the operational safety of gas turbines.

Application Scenarios

- Gas Turbine Control in Thermal Power Plants

In thermal power plants equipped with Mark V series control systems, this board connects to multiple sensors on gas turbines. It processes signals such as the temperature of the turbine combustion chamber collected by thermocouples and the fuel flow pressure signal. The conditioned signals are transmitted to the main control system, which adjusts the fuel injection volume and air intake to ensure the turbine maintains stable power output.

- Petrochemical Gas Turbine Driven Compressor Control

Petrochemical plants often use gas turbines to drive air compressors and natural gas compressors. This board processes the LVDT position signals of the compressor’s control valves and the stall detection signals of the compressor. It ensures the control system can accurately adjust the compressor’s operating state according to the signals, avoiding compressor damage caused by stall and ensuring the smooth progress of petrochemical production processes.

- Industrial Boiler Turbine Control in Refineries

In refineries, small and medium – sized gas turbines are usually used to drive industrial boilers. This board receives and conditions the vibration signals of the turbine and the temperature signals of the boiler flue gas. It transmits reliable data to the control system to help operators monitor the operating status of the turbine in real – time and adjust parameters in time to ensure the boiler’s heating efficiency and the turbine’s operational stability.

- Maintenance of Legacy Gas Turbine Control Systems

Many industrial facilities still operate legacy gas turbine control systems of the Mark V series. When the original analog I/O board malfunctions, resulting in distorted signals or interrupted signal transmission, replacing it with the DS3800HFPB1F1E can quickly restore the signal processing function of the system. This replacement avoids long – term production shutdowns caused by component failures and reduces economic losses for enterprises.

- Marine Gas Turbine Auxiliary Control

In ships using GE Mark V series control systems, this board is applied to the auxiliary gas turbine control system. It processes the servo valve output signals and fuel flow signals of the marine gas turbine, adapting to the harsh marine environment with high humidity and vibration. It ensures the stable operation of the auxiliary gas turbine, providing reliable power support for ship navigation and on – board equipment.

Reviews

There are no reviews yet.