Product Short Description

Technical Specifications

- Electrical Parameters

- It operates with a 24VDC power supply and has a rated power of 59W, which provides stable power support for its internal signal processing and communication functions.

- It specializes in receiving 4 – 20mA analog input signals, which are the standard signals for most industrial temperature, pressure and flow sensors.

- The analog – to – digital converter integrated inside the board delivers high – resolution conversion, which guarantees the accuracy of the converted digital signals and lays the foundation for precise control of turbines.

- Hardware and Communication Parameters

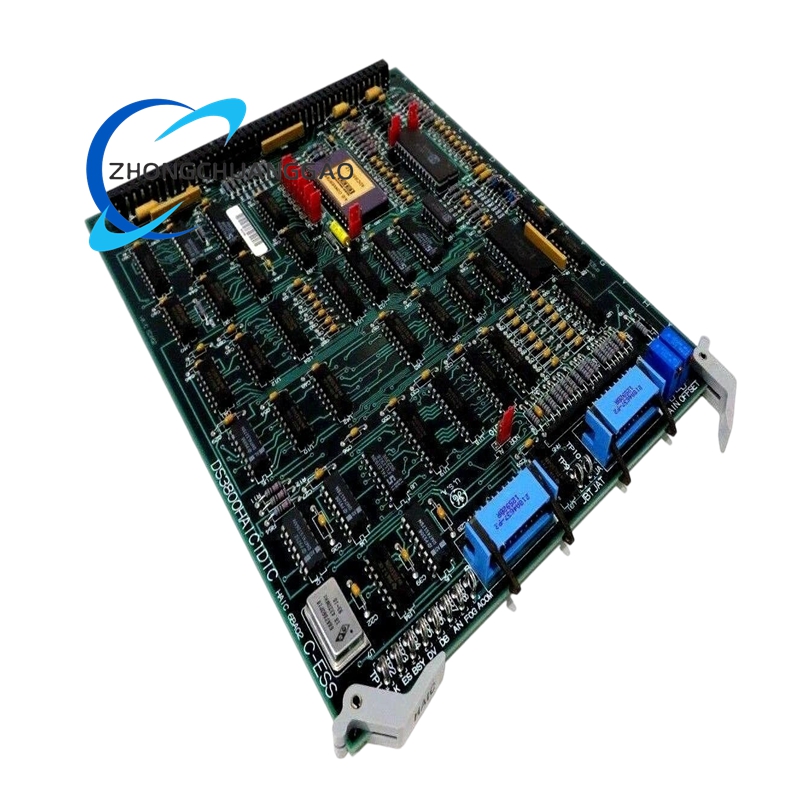

- It is equipped with 9 jumpers and 2 trimmer resistor components. The jumpers are used to configure specific functions of the board, and the trimmer resistors enable fine – tuning of electrical parameters for performance calibration.

- It is fitted with a 20 – pin connector and a modular connector. The 20 – pin connector is used to connect ribbon cables for external device expansion, while the modular connector realizes power supply and signal transmission with the matching connector at the rear of the board rack.

- It fully supports the HART protocol to achieve seamless bidirectional communication with HART – compatible smart sensors and the upper – level control system.

Description

- Physical and Environmental Parameters

- It has a weight of 2.00 lbs and dimensions of 8.25 cm in height and 4.18 cm in width, featuring a compact structure that fits the standard slot of the Mark IV system rack for easy installation.

- It has an operating temperature range of -30°C to 65°C, which can adapt to the large temperature fluctuations in industrial workshops and turbine rooms.

- It adopts a rugged design that resists humidity, vibration and electromagnetic interference, allowing stable operation in harsh industrial environments with high dust and strong electromagnetic fields.

Function Features

- High – Precision Signal Conditioning and Conversion

The board is equipped with dedicated signal conditioning and isolation circuits. It filters out electrical noise and interference common in high – power turbine environments from the received analog signals, which ensures the integrity and stability of the signals. It then converts the conditioned analog signals into digital data through a high – performance analog – to – digital converter, which eliminates signal degradation during conversion.

- HART Protocol – Based Remote Operation

With HART protocol support, the board enables bidirectional communication between the control system and smart field devices. Maintenance personnel can remotely configure sensor parameters, calibrate detection accuracy and collect real – time operating data through the protocol. This remote operation avoids the need for on – site disassembly and adjustment of equipment, which greatly improves maintenance efficiency.

- Built – in Fault Diagnosis and Anomaly Detection

The board continuously monitors the status of each input channel during operation. It promptly detects anomalies such as open circuits, short circuits, signal drift or sensor failures. Once an anomaly is found, it immediately flags the fault and sends a signal to the main control system, which reminds operators to take corrective measures to prevent minor issues from developing into major turbine failures.

- Convenient Installation and Secure Fixing

It is designed with retention levers that firmly lock the board in the rack after installation to prevent accidental dislodging due to equipment vibration during turbine operation. The modular connector and 20 – pin connector follow standard industrial interfaces, which allows quick connection with matching components and simplifies the installation process. Technicians can complete the installation with simple alignment and insertion operations.

Application Scenarios

- Gas Turbine Control in Thermal Power Plants

In thermal power plants using Mark IV Speedtronic control systems, this board connects to temperature sensors on turbine combustion chambers and pressure sensors on steam pipelines. It converts the collected analog signals into digital data and transmits them to the main control system. The system adjusts fuel injection volume and air intake based on this data to maintain stable power output of the turbine and improve power generation efficiency.

- Petrochemical Gas Turbine Auxiliary Control

Petrochemical plants often use gas turbines to drive compressors and pumps in production lines. This board processes analog signals from flow sensors in oil and gas pipelines and vibration sensors on turbines. Through the HART protocol, it sends fault warnings to the control center when it detects abnormal flow or excessive vibration, which helps avoid equipment damage and production interruptions caused by component failures.

- Industrial Boiler Turbine Monitoring in Refineries

Refineries rely on small – and medium – sized gas turbines to drive industrial boilers. This board receives analog signals from thermocouples and pressure transmitters on the boilers. It conditions and converts these signals to monitor the boiler’s internal temperature and pressure in real time. The control system adjusts the turbine’s operating parameters according to the processed data to ensure the boiler operates within a safe parameter range.

- Legacy System Maintenance in Chemical Plants

Many chemical plants still operate gas turbines with Mark IV control systems. When the original analog input board malfunctions and causes signal distortion or communication interruption, replacing it with the DS3800HAIC – 1D1C – 813599 can quickly restore the signal conversion and transmission functions of the control system. It avoids long – term production shutdowns and reduces economic losses for enterprises.

- Gas Turbine Control in Cogeneration Plants

In cogeneration plants that simultaneously produce electricity and heat, this board connects to multiple sensors on the gas turbine. It integrates and converts signals such as exhaust gas temperature, rotational speed and fuel flow. The converted data enables the control system to balance the power generation and heating efficiency of the turbine, which achieves optimal utilization of energy resources.

Reviews

There are no reviews yet.