Product Short Description

Technical Specifications

-

- Electrical Parameters

- It operates on a 24VDC rated voltage with a ±10% fluctuation tolerance, and it can also adapt to an 88VDC working voltage environment to meet diverse industrial power supply requirements.

- Each of its 30 plug-in SPST relays has a 0.5-amp contact rating, and the relays can withstand 5A current at 250V AC or 30V DC, supporting the control of multiple high-current loads simultaneously.

- It integrates 1500V AC signal isolation capabilities that last for 1 minute, effectively preventing electrical interference between the board and connected external devices.

- It has a full-load power consumption of no more than 5 watts and a relay response time of less than 10 milliseconds for both energization and release, ensuring rapid execution of control commands.

- Interface and Structural Parameters

- It is equipped with four 34-pin connectors and four 12-pin connectors. The 34-pin connectors are assigned specific identifiers for signal distribution, while the 12-pin connectors are used for auxiliary signal transmission, facilitating quick and standardized connection with other system modules.

- It adopts spring clamp terminal blocks that enhance connection stability and simplify wiring and disassembly during maintenance.

- It supports industrial communication protocols including Modbus RTU/TCP and GE Genius Bus, enabling seamless data interaction with the Mark V LM system’s main control unit.

- Electrical Parameters

Description

- Physical and Environmental Parameters

- It weighs 3 pounds and has compact dimensions that fit perfectly into the standard slot of the Mark V LM system cabinet, saving installation space and simplifying layout.

- It has an operating temperature range of -40°C to 85°C and a storage temperature range of -40°C to 70°C. It can operate stably in environments with a 5%-95% humidity range without condensation.

- It holds an IP65 protection rating that effectively prevents dust and liquid intrusion, adapting to dusty and humid industrial on-site conditions.

Function Features

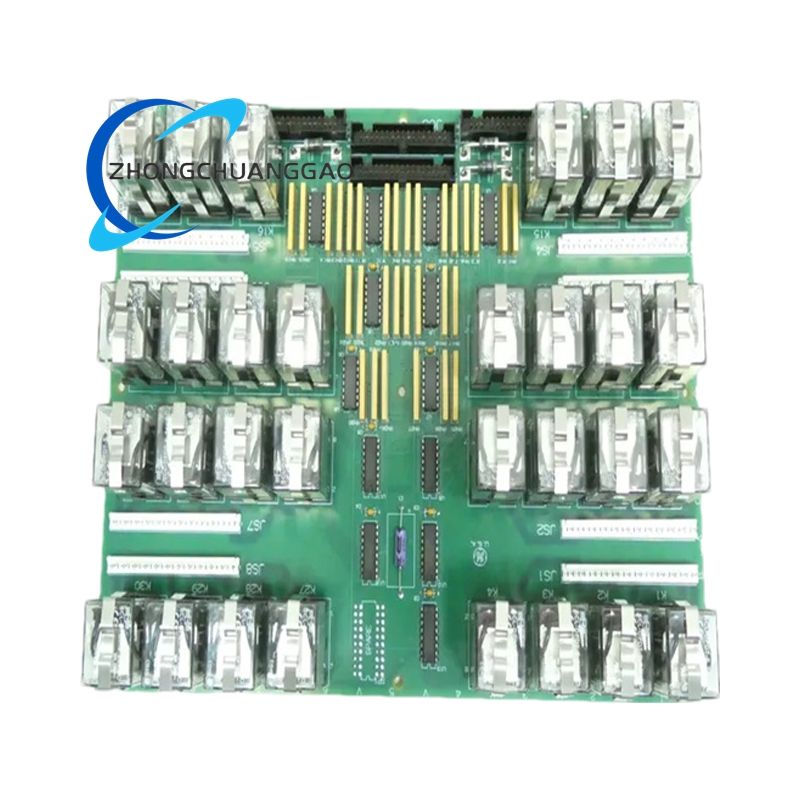

- Multi-Channel High-Reliability Relay Control

The 30 plug-in relays on the board allow simultaneous independent control of 30 sets of external electrical equipment. The standardized plug-in design of the relays facilitates quick replacement when individual relays fail, without the need to replace the entire board, thus reducing maintenance costs and downtime.

- Comprehensive Electrical Protection and Isolation

It is equipped with overload and short-circuit protection mechanisms that immediately cut off the relevant circuits when abnormal currents occur due to equipment malfunctions. Combined with its 1500V AC signal isolation function, it not only protects the board itself from damage but also isolates the Mark V LM system’s core control unit from external electrical interference, ensuring the overall stability of the system.

- Intuitive Status Monitoring for Easy Troubleshooting

The board is fitted with LED indicator lights corresponding to each relay channel. The lights clearly display the energized or de-energized state of each relay. Maintenance personnel can directly observe the indicator status to quickly identify faulty relay channels without complex testing equipment, greatly shortening the fault diagnosis cycle.

- Seamless Compatibility and Modular Expansion

It is fully compatible with the Speedtronic Mark V LM turbine control system and requires no additional hardware modifications or software programming during installation. Its modular design allows for flexible configuration based on the number of external loads, and its standard communication protocols and connectors enable easy integration with other automation components, supporting system function expansion.

Application Scenarios

- Thermal Power Plant Steam Turbine Load Control

It is extensively used in the Mark V LM control systems of steam turbines in thermal power plants. It connects to steam valves, feed pump motors, and exhaust gas control dampers. It executes on-off commands from the main control unit to adjust steam intake volume and load output. Stable relay switching ensures the turbine maintains a constant speed and stable power generation efficiency.

- Oil and Gas Refinery Gas Turbine Auxiliary Control

In oil and gas refineries, gas turbines are commonly used to drive large compressors and transfer pumps. This board integrates into the supporting Mark V LM systems to control the on-off of lubrication pumps, ignition systems, and emergency shutoff valves of the turbines. Its signal isolation and protection functions ensure safe operation even in environments with flammable gases.

- Nuclear Power Plant Turbine Safety System Control

It serves in the auxiliary control systems of nuclear power plant turbines. It controls safety-related components such as coolant circulation pumps and pressure relief valves. Its high-temperature resistance and stable switching performance ensure that these safety components respond promptly to control signals, which is crucial for maintaining the safe and stable operation of nuclear power generation equipment.

- Metallurgical Plant Turbine-Driven Equipment Regulation

Metallurgical plants use turbines to power blast furnace blowers and smelting auxiliary equipment. This board connects to the Mark V LM control systems of these turbines. It regulates the on-off state of temperature control valves and material conveying pumps according to smelting process requirements. Its dust-proof and moisture-proof design adapts to the harsh environment of metallurgical workshops.

- Legacy Mark V LM System Maintenance in Chemical Industry

Many chemical plants still operate legacy Mark V LM turbine control systems to drive reactors and material mixing equipment. This board acts as a key spare part for these systems. When the original relay output board fails and causes equipment control delays or malfunctions, replacing it with the DS200TCRAG1ACC can quickly restore the system’s switching control capabilities, minimizing production interruptions and economic losses.

Reviews

There are no reviews yet.