Product Short Description

Technical Specifications

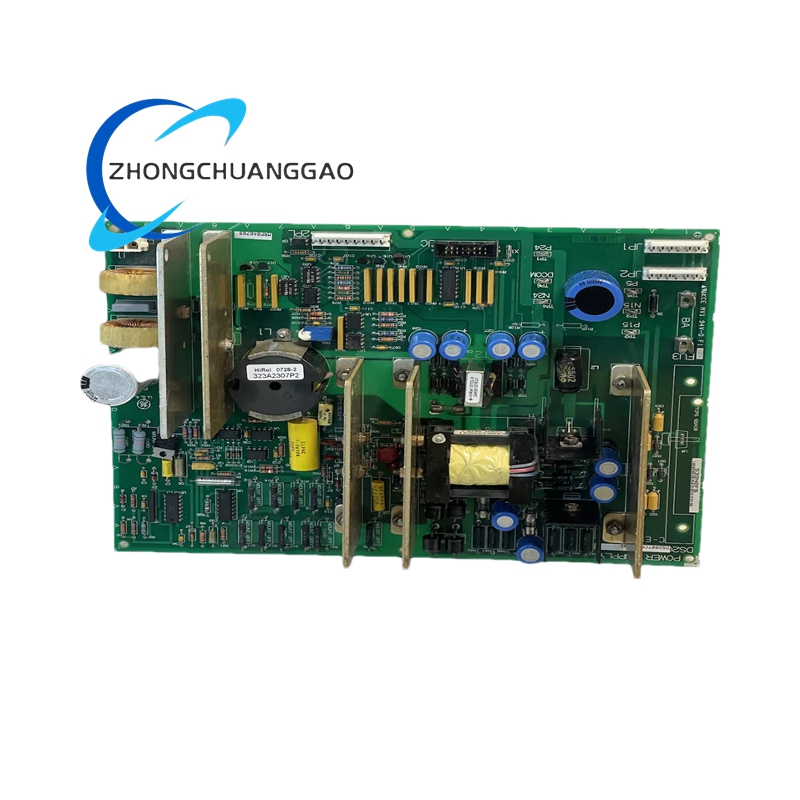

- Electrical Parameters

- It accepts a 125VDC input voltage from the TCPD board and stably outputs multiple standard voltages including +5VDC, +24VDC, ±15VDC, and ±24VDC to match the power demands of different system modules.

- It comes with three built-in fuses that protect three separate circuits on the board respectively, with a rated current of 5A to cut off circuits immediately when overcurrent occurs.

- It supports analog input methods to adapt to the power signal transmission requirements of the Mark V system and ensures compatibility with the power distribution logic of the entire control system.

- Interface and Structural Parameters

- It is equipped with multiple specialized connectors, including a 16-pin connector, a 9-pin connector, and functional connectors such as J1, JC, JP1, and JP2. The J1 connector receives 125VDC power, while JC, JP1, and JP2 distribute power to different matching boards.

- It is designed with multiple test points that allow technicians to use professional instruments to detect circuit status and quickly locate power supply or connection faults.

- It has no hardware jumpers or software configuration requirements, which simplifies the installation and commissioning process and avoids operational errors caused by incorrect configuration.

Description

- Physical and Environmental Parameters

- It has a weight of 1.2 kilograms and dimensions of 27.8cm×21.2cm×6.5cm, featuring a compact structure that fits the standard slot size of the Mark V system’s core modules.

- It operates stably within a wide temperature range of -20°C to 100°C, adapting to the high-temperature and low-temperature fluctuations common in industrial sites.

Function Features

- Precise Multi-Voltage Conversion and Distribution

The board efficiently converts the single 125VDC input into multiple required output voltages. It distributes these voltages to different functional modules through connectors like JC, JP1, and JP2 in a daisy-chain or targeted way. This function ensures that each component in the turbine control system, from high-power servo valves to sensitive microprocessors, receives the exact voltage it needs for operation.

- Reliable Overcurrent Protection with Fuses

The three dedicated fuses on the board form a first-line protection barrier for the circuit. When irregular or excessive current flows through the board due to short circuits or component failures, the fuses trigger and shut down the corresponding circuits promptly. This prevents damage to the board itself and avoids cascading damage to expensive core components connected to it.

- Simplified Fault Diagnosis with Test Points

The multiple test points on the board enable straightforward troubleshooting. When the system power supply malfunctions, technicians can directly measure electrical parameters at these test points without disassembling the entire system. This approach shortens the time spent identifying issues such as poor contact, fuse burnout, or voltage loss, and improves the efficiency of maintenance work.

- Hassle-Free System Compatibility

It achieves seamless integration with the Mark V system without the need for additional hardware modifications or software programming. Its standardized voltage output and connector design ensure consistent compatibility with various functional boards in the system. The plug-and-play design allows technicians to quickly replace faulty boards, minimizing downtime for the turbine control system.

Application Scenarios

- Thermal Power Plant Turbine Power Supply

It is widely used in the Mark V control systems of gas and steam turbines in thermal power plants. It provides stable power for turbine speed sensors, fuel valve control modules, and exhaust temperature monitoring components. Stable voltage output ensures accurate execution of turbine start-stop, load adjustment, and emergency shutdown commands, which is critical for maintaining continuous power generation.

- Petrochemical Plant Compressor Turbine Control

In petrochemical refineries, many compressors and transfer pumps are driven by steam turbines controlled by the Mark V system. This board supplies power to the turbine’s pressure control valves and flow sensors. It maintains stable operation even in harsh environments with high humidity and flammable gas, ensuring the safety and continuity of oil and gas compression and transportation processes.

- Mining Industry Auxiliary Turbine Operation

Mining sites use turbines to power large ventilation equipment and conveyor systems. The DS200TCPSG1A board is integrated into the supporting Mark V control systems. It converts and distributes power to ensure the stable operation of turbine control components under harsh conditions such as large vibration and heavy dust, preventing production interruptions caused by power supply failures.

- Legacy Mark V System Maintenance in Metallurgy

Many metallurgical plants still rely on legacy Mark V turbine control systems to power blast furnaces and smelting equipment. This board serves as a key spare part. When the original power supply board fails, replacing it with the DS200TCPSG1A can quickly restore the power supply of the control system, reducing downtime and avoiding losses caused by interrupted smelting processes.

- Offshore Platform Turbine Power Regulation

Offshore oil and gas platforms use turbines for power generation and equipment driving. The board adapts to the marine environment with high salt spray and humidity. It provides stable multi-voltage power for the Mark V-based turbine control system, ensuring reliable transmission of emergency shutdown signals and speed control signals. This protects the safety of offshore equipment and operators.

Reviews

There are no reviews yet.