Product Short Description

Technical Specifications

- Processor and Display Parameters

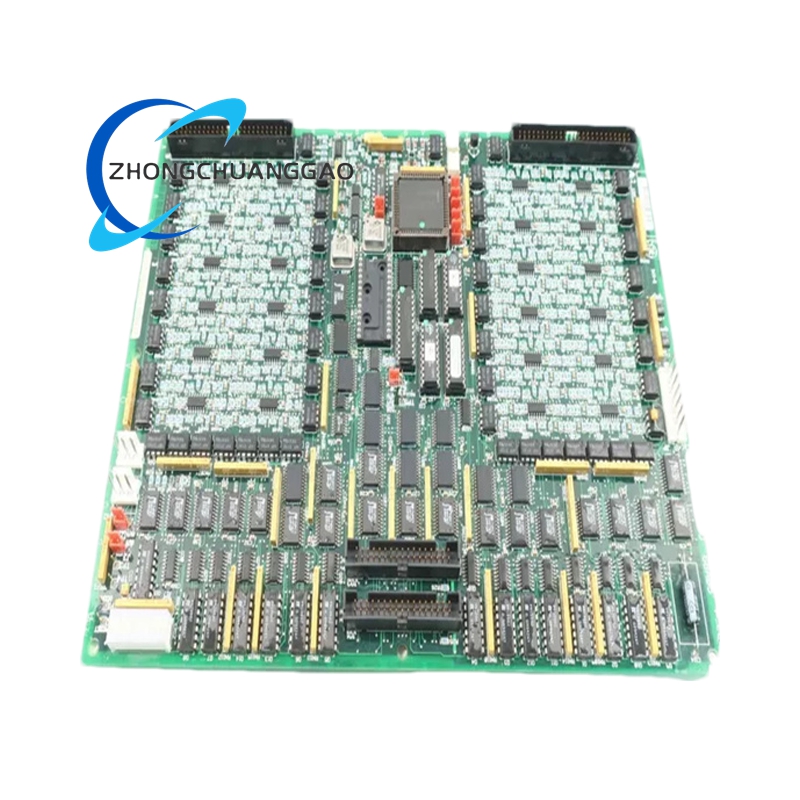

- It is equipped with a dedicated microprocessor that manages core tasks including digital signal decoding, logical judgment, and output signal encoding, ensuring rapid and accurate processing of various digital signals in the turbine control system.

- It is fitted with multiple removable programmable read-only memory modules that store the firmware and control logic required for the board’s operation, and these modules can be replaced or updated to adapt to different turbine control requirements.

- It has a single side-visible green LED and a block of 10 LEDs. These indicators provide visual feedback on the board’s overall operating status and the status of key signal channels, enabling technicians to quickly identify operational anomalies.

Description

- Electrical and Connection Parameters

- It is configured with 8 configurable jumpers labeled JP1 to JP8. These jumpers are used to customize the board’s functional parameters, such as signal transmission protocols and channel enablement. The factory default settings meet most standard operating needs, and they can be manually adjusted according to on-site requirements.

- It is furnished with multiple test points prefixed with TP. Technicians can use professional testing equipment to detect individual circuits through these test points, accurately locating repairable faults.

- It comes with diverse connectors, including two 50-pin connectors, two 3-pin connectors (JX1 and JX2), and specialized connectors like JP, JQ, JR, JO1, and JO2. These connectors are responsible for power distribution, digital signal transmission with other boards, and IONet signal daisy-chaining.

- Physical Parameters

- It has a compact structure with dimensions of 16cm×16cm×12cm and a weight of 0.8 kilograms, which is consistent with the standard module size of the Mark V system.

- It is fully compatible with the installation slots of the R1, R2, and R3 I/O cores of the Mark V system, allowing direct installation and replacement without modifying the system cabinet or slot structure.

Function Features

- Efficient Digital Signal Transceiving and Processing

The board efficiently handles bidirectional digital signal transmission. It receives digital contact input signals from DTBA and DTBB boards via dedicated connectors, processes the signals through the built-in microprocessor based on preset logic, and then sends the processed output signals to TCRA boards through JO1 and JO2 connectors. This seamless signal transfer ensures the coordinated operation of all components in the turbine control system.

- Flexible Configuration via Jumpers

The 8 labeled jumpers enable targeted configuration of the board. Technicians can adjust the jumper positions to match the signal requirements of different turbine models and on-site operating conditions. This flexibility eliminates the need for hardware modifications to the board itself and allows it to adapt to a variety of control system configurations, enhancing its versatility.

- Convenient Fault Diagnosis and Maintenance

The combination of LED indicators and dedicated test points simplifies the maintenance process. The LED block shows the status of key signal channels, and the side LED indicates the overall operating state, enabling preliminary fault localization. The test points allow for in-depth circuit testing, helping technicians accurately identify faulty components or circuits, shorten troubleshooting time, and reduce maintenance costs.

- Stable Inter-board Integration and Communication

It achieves standardized communication with other modules in the Mark V system through its diverse connector design. The JX1 and JX2 connectors realize IONet signal daisy-chaining, while the JP connector is responsible for power distribution from the TCPS board. These well-defined connector functions ensure stable data transmission and reliable power supply, laying a foundation for the overall stability of the turbine control system.

Application Scenarios

- Gas Turbine Control in Thermal Power Plants

It is widely used in the Mark V control systems of gas turbines in thermal power plants. It processes digital signals such as start-stop control signals, status feedback signals of fuel valves, and trip signals of the turbine. It ensures the accurate transmission of control commands and real-time feedback of equipment status, helping the central controller adjust the operating parameters of the gas turbine in a timely manner and maintaining stable power output.

- Steam Turbine Control in Petrochemical Plants

In petrochemical refineries and chemical processing plants, this board is integrated into the control systems of steam turbines that drive compressors and transfer pumps. It transmits digital signals between the control system and on-site equipment, such as the opening and closing status signals of pipeline valves and the start-stop control signals of compressors. It ensures the stability of oil and gas compression, transportation, and processing processes and prevents production accidents caused by signal transmission delays or failures.

- Industrial Turbine Maintenance in Metallurgical Industry

Metallurgical plants rely on turbines to provide power for high-power equipment such as blast furnaces and air compressors. The DS200TCDAH1BHD board is used in the Mark V control systems of these turbines to maintain the stability of digital signal transmission. As a key spare part, it can quickly replace faulty boards when they malfunction, reducing production downtime caused by equipment outages and ensuring the continuity of metallurgical production processes.

- Turbine Control in Marine and Offshore Platforms

For turbines on large ships and offshore oil and gas platforms, this board adapts to harsh marine environments such as high humidity and vibration. It is used in the Mark V-based marine turbine control systems to stably transmit digital signals such as turbine speed status signals and emergency shutdown control signals. It ensures the reliable operation of marine turbines and avoids marine safety accidents caused by signal processing failures.

- Auxiliary Turbine Control in Pharmaceutical and Food Industry

In large-scale pharmaceutical and food processing plants, small and medium-sized turbines are often used for power supply and steam generation. This board is integrated into the supporting Mark V control systems. It processes digital signals from equipment such as steam pressure switches and temperature controllers, helping the control system adjust the turbine’s operating state in real time. It ensures the stability of the production environment such as temperature and pressure and meets the strict production standards of the pharmaceutical and food industries.

Reviews

There are no reviews yet.