Product Short Description

Technical Specifications

- Processor and Memory Parameters

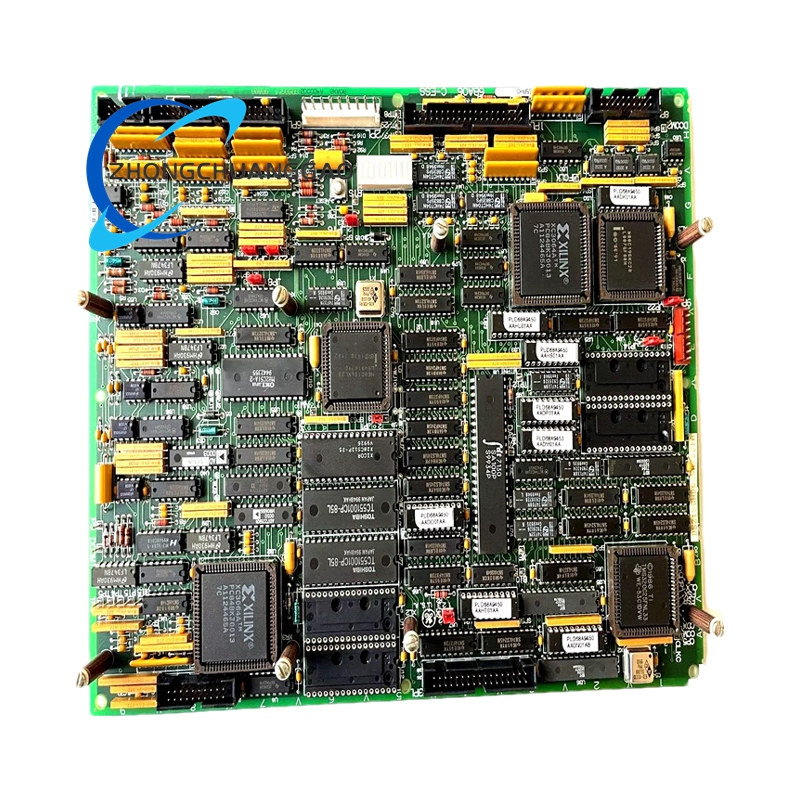

- It is equipped with three dedicated microprocessors, namely a drive control processor, a motor control processor, and a co-motor processor, each responsible for specialized tasks in drive control processing with matching firmware and hardware pre-installed.

- It features five EPROM connectors; four of these store factory-set configuration parameters, while the fifth is reserved for user or maintenance personnel to input custom configuration data.

- Physical Parameters

- It has dimensions of 28cm×23cm×3cm and a weight of 0.55kg, with drilled holes at each corner to enable easy installation in the Mark V control panel.

- Alternative supply specifications show a weight of 2.5kg and dimensions of 20cm×25cm×30cm, adapting to different packaging and installation requirements in industrial scenarios.

- Electrical and Communication Parameters

- It supports multiple communication protocols including Modbus RTU and CAN, and is compatible with RS485 communication interfaces to realize seamless data transmission with upper-level systems and other peripheral devices.

- It adopts input/output isolation and inter-channel isolation technologies to prevent signal interference and ensure the stability of electrical signal transmission.

Description

Function Features

- Specialized Multi-Processor Collaborative Work

The three dedicated microprocessors divide labor and cooperate efficiently. Each processor focuses on its assigned tasks, such as processing motor current regulation signals, executing complex motor control algorithms, and managing system-level drive operations. This architecture eliminates processing delays, ensuring rapid response to turbine start-up, load adjustment, and emergency shutdown signals, thus maintaining stable turbine operation.

- Expandable Functionality via Daughterboard Installation

The standoff structures and vertical pin connectors on the board allow direct installation of daughterboards. These daughterboards can add local area network connection capabilities or enhance the board’s signal processing performance, enabling the DS200SDCCG5AHD to adapt to diverse functional requirements of different turbine models and industrial control scenarios without replacing the main board.

- Convenient Parameter Migration and Rapid Maintenance

The five EPROM connectors simplify maintenance and replacement processes. When replacing a faulty board, users only need to remove the EPROM modules from the old board and install them on the new one. This retains all original configuration data, allowing the drive system to resume operation quickly without reconfiguring parameters, minimizing equipment downtime.

- Convenient Parameter Migration and Rapid Maintenance

- Comprehensive Circuit Protection and Stable Operation

The board integrates input/output isolation and inter-channel isolation designs to avoid signal crosstalk and external electrical interference. It is also equipped with a reset button that allows technicians to quickly restart the board in case of minor malfunctions, preventing system crashes caused by transient faults and ensuring the continuous and stable operation of the turbine control system.

- Seamless Compatibility with Mark V System Architecture

It is fully compatible with the hardware interfaces and communication protocols of the Mark V Speedtronic system. It can directly connect to other modules in the system without additional adapters, and serves as a core component in the C core of the control panel. It perfectly integrates into the system’s overall control logic to realize coordinated operation with modules responsible for functions such as turbine speed regulation and fuel control.

Application Scenarios

- Gas Turbine Control in Power Plants

It is widely used in the Mark V control systems of gas turbines in thermal power plants and industrial power stations. It controls the start-up, shutdown, and speed regulation of gas turbines, processes signals related to fuel injection and exhaust gas treatment, and completes NOx detection to meet environmental protection and emission standards. It ensures stable power output of turbines and improves the overall efficiency of power generation.

- Petrochemical Industry Turbine Drives

In petrochemical refineries and natural gas processing plants, this board is integrated into the control systems of turbines driving compressors and transfer pumps. It regulates the rotational speed and torque of these turbines according to process requirements, ensuring stable pressure and flow during the transportation and processing of oil and gas materials, and avoiding production disruptions caused by drive system failures.

- Metallurgical and Industrial Boiler Supporting Control

In metallurgical plants, it is applied to the control systems of turbines in blast furnace air supply systems, adjusting the air supply volume by controlling turbine operation to maintain stable blast furnace pressure. In industrial boiler systems, it coordinates with the boiler control module to regulate the turbine-driven air blower and induced draft fan, ensuring precise control of boiler combustion temperature and pressure.

- Maintenance of Legacy Mark V Control Systems

It is a key spare part for industries such as energy and manufacturing that still use Mark V systems. When the original drive control board fails, replacing it with the DS200SDCCG5AHD can quickly restore the turbine’s drive and protection functions. This avoids the high cost of replacing the entire control system and extends the service life of existing industrial equipment.

- Exciter Control in Generator Sets

It is used in the excitation control systems of generator sets, where it processes excitation signals and adjusts the excitation current of generators through collaborative work with exciters. It maintains the stability of the generator’s output voltage and frequency, ensuring the safe and reliable integration of generated power into the power grid, which is applicable to both thermal and hydropower generator sets.

Reviews

There are no reviews yet.