Product Short Description

Technical Specifications

-

- Electrical Parameters

- It operates on a 28V DC power supply, which matches the power configuration of the Mark V turbine control system and ensures stable power supply for signal processing.

- It achieves a data transfer rate of 115.2 kbps, supporting efficient signal transmission between the board and other system modules without significant delays.

- It is equipped with an overcurrent protection fuse that shields the board and connected circuits from damage caused by excessive current.

- Interface and Connection Parameters

- It has five wire terminals that can accommodate a total of 33 signal wires, with three terminals each supporting three signal wires and two terminals each supporting twelve signal wires.

- It is fitted with four 2-pin connectors to establish secure connections with external components and other system modules.

- The wire terminals are marked with clear identifiers, facilitating accurate wiring during installation and replacement.

- Electrical Parameters

Description

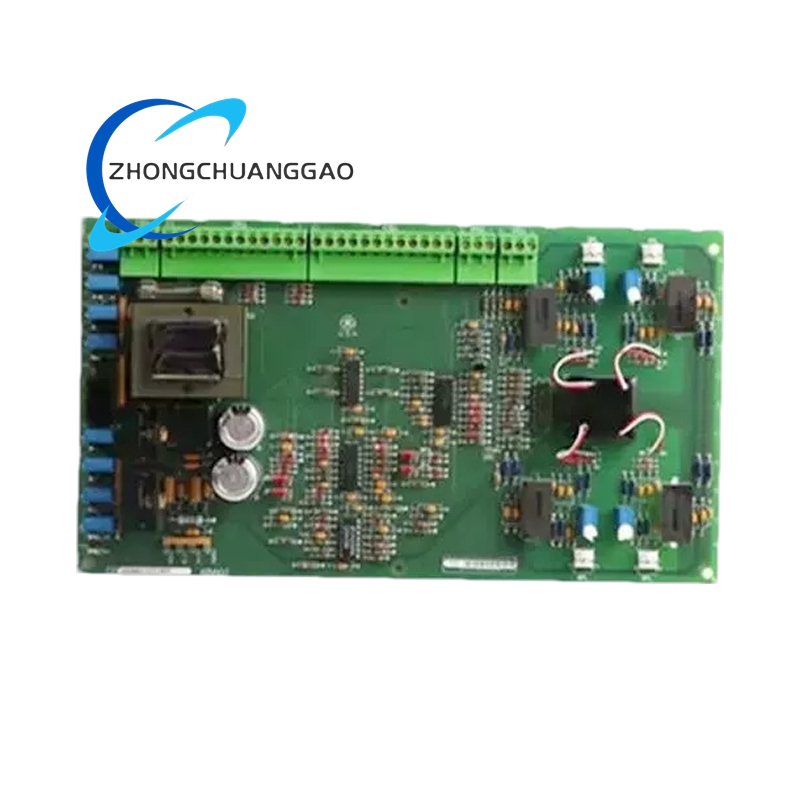

- Physical and Manufacturing Parameters

- It adopts surface mount technology, allowing for high-density component placement with dimensions of 15.9 cm in height and 17.8 cm in width.

- It is manufactured in the United States and adopts a standard VME board design that fits into the standardized card racks of the Mark V system for easy installation.

- It uses screws to fix wires in the terminals, enhancing the stability of wire connections and preventing signal interruptions caused by loose wires.

Function Features

- Efficient Signal Transmission and Management

The five labeled wire terminals of the board can stably transmit and receive up to 33 signal wires simultaneously, which meets the multi-channel signal interaction needs of turbine control systems. The clear terminal identifiers and fixed wire screws avoid signal loss or confusion caused by wiring errors or loose connections, ensuring the accuracy of data transmission between the control system and external execution components.

- Reliable Overcurrent Protection

The integrated fuse on the board provides dedicated overcurrent protection for the circuit. When an abnormal current surge occurs in the system due to faults such as short circuits, the fuse triggers a protective response immediately. This stops the spread of excessive current to the core components of the board and the entire control system, effectively extending the service life of the Mark V system and reducing maintenance costs caused by circuit damage.

- Simplified Installation and Replacement

Each wire terminal on the board is marked with a clear identifier. During maintenance, technicians only need to tag each wire according to the terminal identifier before removing the old board. When installing a replacement board, they can quickly reconnect the wires based on the tags. This design simplifies the replacement process, shortens downtime for system maintenance, and reduces the difficulty of maintenance operations.

- Seamless Compatibility with Mark V System

As a dedicated VME stand I/O board for the Mark V series, it fully matches the system’s hardware architecture and communication protocols. It can be directly installed into the system’s VME slot without additional adaptive modifications or adapter components. It coordinates smoothly with other control modules in the system to form a complete and efficient turbine control network.

Application Scenarios

- Gas Turbine Control Systems

It is widely used in gas turbine control systems in power plants and industrial parks. It transmits signals between the Mark V control unit and the turbine’s ignition system, fuel supply valves, and speed sensors. During the start-up, load adjustment, and shutdown of gas turbines, it ensures timely and accurate transmission of control signals and feedback signals, maintaining the stable operation of gas turbines and preventing operational failures caused by signal transmission delays or errors.

- Steam Turbine Power Generation Units

In thermal power plants, this board is integrated into the Mark V control system of steam turbines. It connects the control unit with steam valves, pressure transmitters, and temperature detectors. It transmits control commands for steam flow and pressure, and feeds back real-time operating parameters of the turbine to the control center. This enables precise regulation of steam turbines, improving power generation efficiency and ensuring the stability of power output.

- Wind Turbine Control Assemblies

It is applied to the control systems of wind turbines in wind power generation projects. It copes with the volatility of wind energy by transmitting signals between the Mark V system and the wind turbine’s pitch control mechanism and generator speed control components. It ensures that the wind turbine can adjust its operating state in real time according to changes in wind speed and direction, maximizing wind energy conversion efficiency while protecting the generator from damage caused by extreme wind conditions.

- Industrial Turbine Maintenance Projects

As a key replacement part for the obsolete Mark V series, it is widely used in maintenance projects of aging industrial turbines in industries such as petrochemicals and metallurgy. Many enterprises that still use Mark V-equipped turbines rely on this board to replace damaged I/O modules. It restores the signal transmission function of the control system without the need for large-scale replacement of the entire control system, saving enterprise maintenance costs.

- Auxiliary Equipment Control in Energy Plants

It is also used in the control systems of auxiliary equipment in energy plants, such as pumps, fans, and conveyor belts that cooperate with turbines. It transmits control signals between the central control system and these auxiliary devices, ensuring that the operating rhythm of the auxiliary equipment matches the working state of the turbines. This guarantees the continuous and efficient operation of the entire energy production line, avoiding production interruptions caused by mismatched operation of auxiliary equipment.

Reviews

There are no reviews yet.