Product Short Description

Technical Specifications

- Processing and Memory Parameters

- It is equipped with a 32 – bit RISC architecture processor that provides strong computing power for processing complex communication tasks and protocol conversion.

- It is configured with 256KB RAM for real – time data temporary storage during communication processing and 2MB Flash ROM for storing system programs and configuration parameters.

- Communication Parameters

- It supports multiple industrial communication protocols including Modbus, HART, Profibus, DeviceNet and Ethernet to adapt to the communication needs of different industrial devices.

- The maximum data transmission rate reaches 100Mbps, and it supports I/A high – speed, Ethernet and Modbus networks to meet the requirements of high – speed data transmission in industrial control.

- Environmental and Physical Parameters

- The working temperature range is from – 40°C to + 70°C, and the storage temperature range is from – 40°C to + 85°C, which can adapt to extreme temperature environments in industrial sites.

- It has an IP67 protection level, which can effectively prevent the intrusion of dust and water and adapt to harsh on – site conditions.

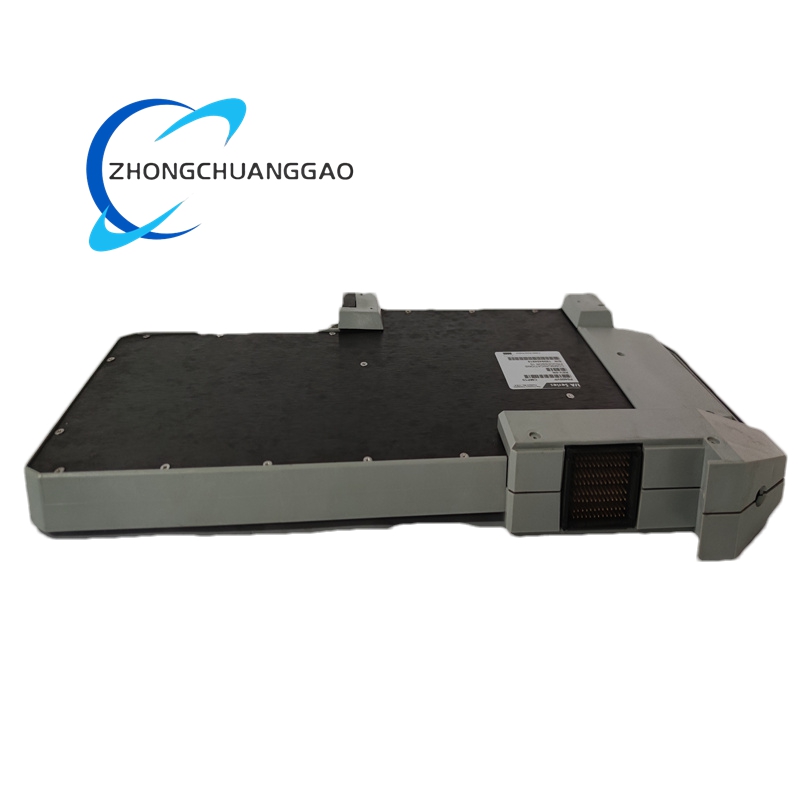

- The physical dimensions are 20 centimeters × 6.2 centimeters × 2.5 centimeters, with a compact structure that is convenient for intensive installation in control cabinets.

Description

- System Configuration Parameters

- It supports redundant configuration, which can be connected with another same module to form a redundant communication link.

- It is fully compatible with Foxboro’s I/A Series distributed control system and can be seamlessly integrated into the existing I/A Series control network.

Function Features

- Multi – Protocol Conversion and Interconnection

The module integrates multiple mainstream industrial communication protocols, which can directly complete the conversion between different protocols without additional adapter modules. It enables smooth information exchange between sensors, actuators, controllers and upper – level monitoring systems that use different protocols, solving the problem of incompatible communication interfaces in mixed industrial equipment environments.

- High – Efficiency Data Processing and Transmission

Driven by the 32 – bit RISC processor, the module can quickly process a large number of concurrent data transmission tasks. With the maximum data transmission rate of 100Mbps, it ensures that industrial control signals and process data are transmitted to the target device in real time. At the same time, it has a data filtering function, which can screen out invalid interference data and improve the accuracy of data transmission.

- Redundant Configuration for High Reliability

The support for redundant configuration greatly enhances the stability of the communication system. When one module fails, the standby module can immediately take over the communication task without interrupting the communication process. This fault – tolerant design avoids system downtime caused by communication module failures and is crucial for industrial production scenarios that require continuous operation.

- Flexible Network Adaptability and Diagnostics

It supports multiple network topologies such as I/A high – speed network, Ethernet and Modbus network, and can be flexibly configured according to the actual layout of the industrial site. In addition, it is equipped with diagnostic and monitoring functions that can real – time monitor the communication status. Once an abnormality such as a communication interruption or a decrease in transmission rate occurs, it can timely feedback the status information to the upper – level system to facilitate maintenance personnel to quickly locate and solve problems.

Application Scenarios

- Oil and Gas Industry

It is used in oil drilling platforms, natural gas processing plants and long – distance pipeline control systems. It connects pressure sensors, flow meters, valve actuators and central control systems. It realizes high – speed transmission of data such as oil and gas flow and pipeline pressure, and completes protocol conversion between on – site devices and the I/A Series DCS. It ensures that the control center can timely adjust the operation parameters of pumping equipment and valves to ensure the safety and efficiency of oil and gas extraction and transportation.

- Chemical Industry

In chemical production workshops, it is deployed in the control systems of reaction kettles, distillation towers and storage tanks. It connects temperature, pressure and concentration sensors with the central controller. It realizes real – time communication between various devices, and the control system can adjust the feeding speed and heating power in a timely manner according to the transmitted data. It prevents dangerous situations such as overpressure and over – temperature in chemical reactions and ensures the stability of the production process.

- Power Generation Industry

It is applied in thermal power, hydropower and other power plants, especially in boiler, steam turbine and power transmission and distribution control systems. It connects various detection devices and control modules in the power generation process. It realizes the transmission of parameters such as steam temperature, pressure and generator output power. It ensures that the central control system can accurately and quickly adjust the operation state of the equipment, maintaining the stable output of electric energy and improving the efficiency of power generation.

- Water Treatment Industry

In urban sewage treatment plants and industrial wastewater treatment systems, it connects liquid level sensors, pollutant concentration detectors, water pumps and dosing equipment. It realizes data communication between on – site equipment and the control system. The system can adjust the start and stop of water pumps and the dosage of drugs according to real – time data such as water inflow and pollutant concentration to ensure that the treated water meets the discharge standards.

- Food and Beverage Industry

It is installed in automatic production lines such as food processing and beverage filling. It connects temperature sensors on cooking equipment, pressure sensors on filling pipelines and weight detectors on packaging machines. It realizes the communication between these devices and the upper – level control system. It ensures that parameters such as food processing temperature, beverage filling volume and packaging weight are within the standard range, maintaining the consistency of product quality.

Reviews

There are no reviews yet.