Product Short Description

Technical Specifications

- Processor and Memory

- It adopts an ARM system – on – chip (SoC) that delivers strong computing power to support the simultaneous operation of multiple complex control algorithms.

- It is configured with 128MB SDRAM for real – time storage of process data during operation and 128MB flash memory for storing system programs and configuration parameters. It also has ECC (Error – Correcting Code) technology that can correct single – bit errors and detect multiple – bit errors to ensure data accuracy.

- I/O and Fieldbus Capabilities

- It can support up to 128 FBMs in total, which can be a mix of 100 and 200 series FBMs. Each PIO bus or baseplate port can connect a maximum of 64 100 series FBMs.

- It communicates via HDLC fieldbus, with transmission rates of 2Mbps for 200 series FBMs and 268Kbps for 100 series FBMs. It is also equipped with dual 100Mbps Ethernet ports that can use either fiber or copper cables for connection.

- It can handle up to 18,000 OM scanner points when the basic control period (BPC) is no less than 200ms, and 7,500 OM scanner points when the BPC is no more than 100ms, along with 11,250 OM sink points.

Description

- Performance Metrics

- It can support a maximum of 8,000 configurable control blocks and achieve 16,000 block executions per second, with a minimum BPC of 50ms.

- It can establish a total of 231 IPC connections, including 200 source connections and 30 sink connections. It has 15.75MB of memory for blocks with classic OLUG and 19.75MB with enhanced OLUG.

- Power and Environmental Specifications

- It uses a redundant 24V DC power input. The power consumption is 11W for a single module and 20W when configured as a fault – tolerant pair.

- The operating temperature range is -20°C to 60°C, and the storage temperature range is -40°C to 70°C. It can operate normally in an environment with 5% – 95% non – condensing humidity and at an altitude of -300 meters to 3,000 meters during operation.

- It adopts a ventless die – cast aluminum housing, which can withstand Class G3 harsh environments, resist 0.5g vibration within the 5 – 500Hz range, and endure 30g half – sine wave impact.

Function Features

- Patented Fault – Tolerant Design for Uninterrupted Operation

It supports dual – module fault – tolerant configuration. The time for module pairing is less than 0.5 seconds. During operation, the two modules conduct continuous runtime self – checks and synchronization. When the main module malfunctions, the backup module immediately takes over the work. This design maximizes the reduction of downtime in critical applications and ensures non – stop operation of the industrial control system.

- Powerful Control and Flexible Expansion

It integrates regulatory, logic, timing, and sequential control functions and supports advanced control algorithms such as PID and feedforward control to meet diverse control requirements of industrial processes. It can connect up to 128 FBMs without relying on additional expansion modules. The flexible combination of compatible 100 and 200 series FBMs allows it to adapt to different scale and type of industrial control system configurations, easily coping with the expansion of production lines.

- Convenient Maintenance and Remote Management

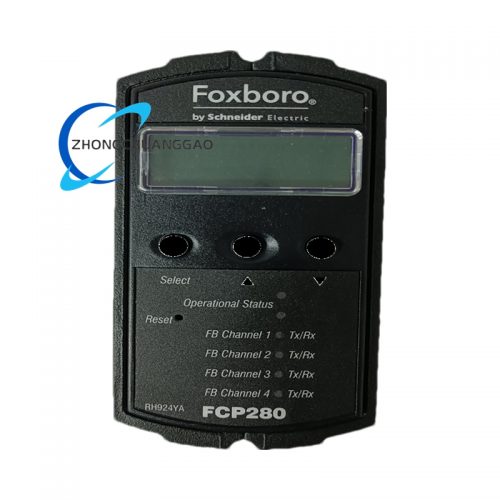

It supports online image upgrade (OLUG) with both classic and enhanced OLUG options, enabling firmware updates during system operation. It allows remote configuration and maintenance, so engineers can adjust parameters and troubleshoot without on – site operations. It is equipped with an LCD to display the module’s role and status, and LED indicators to show module health and communication conditions, facilitating staff to quickly grasp the device’s operating status.

- Secure and Independent Operation Capabilities

It has passed ISA EDSA cybersecurity certification, which can effectively resist network security threats and protect the safety of the industrial control system and process data. Its self – hosting mode allows it to operate independently relying on the stored control database when the host workstation is offline, although the editing of control functions is not available in this mode, it ensures the continuity of the basic control process.

Application Scenarios

- Oil and Gas Industry

It is extensively applied in upstream oil drilling, midstream oil and gas transmission, and downstream refining plants. It connects with FBMs that monitor pipeline pressure, oil and gas flow, and valve status. It precisely controls the speed of pumping equipment and the opening and closing of pipeline valves through preset logic. Its fault – tolerant design and rugged housing can withstand harsh environmental factors such as marine salt spray, desert dust, and drilling site vibration, ensuring the stable operation of oil and gas extraction, transmission, and refining processes.

- Chemical and Specialty Chemical Industry

It is deployed in production lines with key equipment like reaction kettles and distillation towers. It collects real – time data such as temperature, pressure, and material concentration in chemical reactions. It accurately regulates the feeding speed of raw materials and the discharge flow of finished products to ensure that chemical reactions proceed within the set parameters. Its high – speed block execution capability enables rapid response to subtle changes in process parameters, preventing safety accidents caused by parameter deviations and improving product quality and production efficiency.

- Power Generation Industry

It is integrated into thermal power, hydropower, and other power generation facilities. In thermal power plants, it links the control systems of boilers and steam turbines with field devices. It adjusts the coal feeding quantity and air supply volume according to the changes in grid load, and controls the steam pressure and temperature to maintain the generator set running stably at the rated power. The dual 100Mbps Ethernet ports ensure the rapid transmission of a large amount of power operation data, and the fault – tolerant configuration avoids power outages caused by control module failures, ensuring the stability of power supply.

- Pharmaceutical Industry

It plays a crucial role in the automated production lines of the pharmaceutical industry. It strictly controls parameters such as temperature, humidity, and mixing speed in the drug synthesis and preparation processes. It records the entire production process data in detail to meet the strict traceability requirements of the pharmaceutical industry. Its stable and precise control capabilities ensure the consistency and reliability of drug quality, and its secure operation features prevent data tampering that may affect drug safety.

- Food and Beverage Industry

It is used in large – scale food and beverage processing lines, such as milk pasteurization and beverage filling lines. It accurately controls the pasteurization temperature and duration to eliminate harmful bacteria while retaining the nutritional components of food. In the filling process, it regulates the filling speed and volume to ensure that each product has a uniform filling amount. Its ability to resist harsh environments can adapt to the humid and dusty conditions in food processing workshops, and its easy – to – maintain feature reduces the impact of equipment maintenance on production schedules.

Reviews

There are no reviews yet.