Product Short Description

Technical Specifications

- I/O Channel Parameters

- It is equipped with 24 independent discrete input channels and 8 independent discrete output channels, all adopting group isolation design.

- It supports three voltage specifications for input and output signals, including 15 – 60V DC, 120V AC/125V DC and 240V AC, and is compatible with dry contact type input and output.

- The response time is less than 20 milliseconds, and the input filter time can be configured according to actual needs to adapt to different signal stability requirements.

- Electrical Specifications

- The standard power supply is 24V DC with a voltage tolerance of ±10%, and the maximum power consumption does not exceed 6W.

- The matching termination assemblies are equipped with high-voltage attenuation components and optical isolation parts, which effectively isolate external electrical interference and protect the module circuit.

- The termination assemblies integrate current-limiting devices and fuses, and support relay outputs with internal or external power supply and fusing configurations.

- Physical & Environmental Specifications

- The module dimensions are 138mm × 112mm × 44mm, weighing about 0.5kg, with a rugged aluminum housing structure.

- It supports DIN rail mounting and 19-inch rack mounting, and the maximum length of the matching connection cable can reach 30 meters.

- The operating temperature ranges from -40°C to +85°C, and the storage temperature is consistent with the operating temperature range. It adapts to 5% – 95% non-condensing humidity, and has a protection level of IP66.

Description

Function Features

- Multi-Specification Voltage Support and Strong Compatibility

The module supports three common industrial voltage specifications for discrete signals, which can be directly connected to limit switches, electromagnetic valves, contactors and other devices with different voltage requirements without additional signal conversion components. It is compatible with Modbus protocols and can seamlessly connect with Foxboro I/A Series DCS, greatly reducing the difficulty of system integration and adapting to the matching needs of different automation systems.

- Comprehensive Protection and High Operational Stability

It adopts optical isolation technology and high-voltage attenuation circuits to effectively suppress electromagnetic interference and voltage surges in industrial environments and avoid signal distortion or module damage. The matching termination assemblies are equipped with independent current-limiting devices and fuses, which can cut off the circuit in time when the current is abnormal. The aluminum housing enhances the module’s resistance to impact and corrosion, ensuring stable operation in harsh industrial conditions such as dust and vibration.

- Intuitive Status Monitoring and Rapid Response

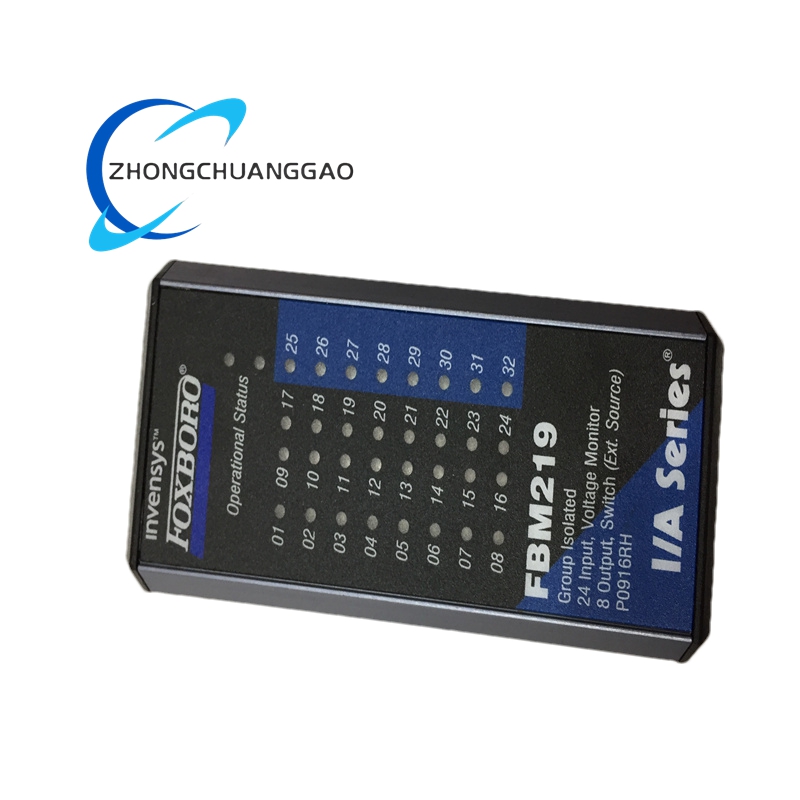

The front-end LED indicators can directly reflect the overall operating status of the module and the real-time state of each input and output channel. Operators can quickly locate faults without disassembling the equipment. With a response time of less than 20 milliseconds, the module can quickly collect the status signals of field devices and execute the control commands issued by the DCS, ensuring the real-time performance of the industrial control process.

- Flexible Configuration and Easy Installation

It provides configurable functions such as input filter time and fault-safe configuration, and users can set parameters according to the stability of field signals and the safety requirements of the control process. The module supports two mounting methods: DIN rail and rack, which can be flexibly installed according to the layout of the control cabinet. The simple wiring design and matching termination assemblies also facilitate on-site installation, commissioning and later maintenance.

Application Scenarios

- Oil and Gas Industry

It is deployed in oil drilling platforms, natural gas processing plants and long-distance pipelines. The input channels collect status signals from pipeline valve limit switches, tank level control switches and actuator position sensors. The output channels send control signals to solenoid valves and emergency shut-off devices. When abnormal signals such as excessive pipeline pressure are detected, the module can quickly transmit commands to shut down related equipment, avoiding safety accidents such as oil and gas leakage.

- Power Industry

It is widely used in thermal power plants, hydropower stations and substations. It connects with circuit breaker status sensors, transformer temperature alarm switches and cooling system water level switches through input channels. It controls the start and stop of auxiliary pumps, the switching of power supply branches and other operations through output channels. The rapid response capability ensures that the central control system can timely handle faults such as transformer overheating, preventing large-scale power outages and ensuring stable operation of the power grid.

- Water Treatment Industry

It is installed in urban sewage treatment plants and water supply pumping stations. The input channels collect discrete signals such as sedimentation tank overflow alarm switches, filter blockage sensors and dosing pump operation status. The output channels control the start and stop of water pumps, the opening and closing of dosing valves and the switching of filter backwashing devices. The stable signal transmission ensures the continuity of the water treatment process and guarantees that the treated water quality meets the set standards.

- Food Processing Industry

It is integrated into automated food production lines, such as beverage filling lines and frozen food processing lines. The input channels monitor the status of conveyor belt position switches, filling nozzle in-place sensors and sterilization cabinet door interlock switches. The output channels control the operation of conveyor motors, the on-off of filling valves and the start of sterilization procedures. The module’s reliable performance ensures the standardization of each production link and avoids production interruptions caused by signal transmission errors.

- Automotive Manufacturing Industry

It is applied in automobile assembly lines and parts processing workshops. It collects signals from mechanical arm position sensors, fixture clamping switches and assembly line stop buttons through input channels. It sends control commands to fixture locking devices, conveyor line driving mechanisms and alarm buzzers through output channels. The group isolation design prevents signal interference between multiple devices on the production line, ensuring the accuracy and efficiency of automobile assembly and parts processing.

Reviews

There are no reviews yet.