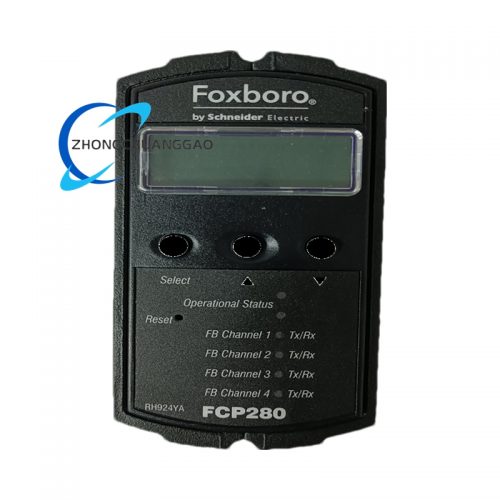

Product Short Description

Technical Specifications

- Input & Conversion Parameters

- It is configured with 8 group – isolated input channels, and each channel accepts 4 – 20mA analog signals or HART FSK signals superimposed on 4 – 20mA signals.

- It achieves a measurement accuracy of ±0.03% of full scale, a temperature coefficient of 50 ppm/°C, and a 15 – bit resolution to ensure signal measurement precision.

- The signal update rate reaches 100ms per channel, and it can transmit up to two digital messages per second with each connected HART field device.

- Electrical & Communication Specifications

- It adopts a 24V DC power supply with a voltage tolerance of ±5%, and the power consumption is no more than 2.5W. Each channel can provide an isolated current – limited loop power supply when needed.

- It complies with HART FSK physical layer specification HCF_SPEC – 54 revision 8.1, and the maximum length of connected termination cables can reach 30 meters.

- The 8 input channels are galvanically isolated from the ground and module logic, and the nominal input impedance of the channels is 61.9Ω with a minimum total input resistance of 280Ω.

Description

- Physical & Environmental Specifications

- The module weighs about 284g, with a height of 102mm or 114mm including mounting lugs, a width of 45mm and a depth of 104mm. It can be mounted on din rails or 19 – inch racks.

- It operates at a temperature range of -20°C to 70°C, and the PVC termination assembly works at -20°C to 50°C while the PA termination assembly shares the same operating temperature range as the module.

- It adapts to 5% – 95% non – condensing humidity and can operate at an altitude of -300m to 3000m and be stored at an altitude of -300m to 12000m. It can resist 7.5m/s² vibration in the frequency range of 5 – 500Hz.

Function Features

- Dual Signal Compatibility and Bidirectional Communication

Each channel can be flexibly matched with standard 4 – 20mA analog devices and HART digital devices, which allows mixed connection of different types of field sensors without modifying the module hardware. The dedicated FSK modem for each channel supports bidirectional digital communication, enabling the DCS to not only collect process data but also retrieve diagnostic information and configure parameters of HART devices.

- High-Precision Signal Conversion and Isolation Protection

It adopts sigma – delta data conversion technology for each channel to ensure high – precision conversion of analog signals. The galvanic isolation design of the input channels isolates the channels from the ground and module logic, which eliminates signal crosstalk between channels and prevents module damage caused by external voltage surges or electromagnetic interference, enhancing the stability of signal transmission.

- Strong Environmental Adaptability

The rugged extruded aluminum casing and compliance with ISA S71.04 G3 – class environmental standards enable the module to withstand harsh conditions such as dust, chemical corrosion and vibration on industrial sites. Its wide operating temperature range and humidity adaptability ensure stable operation in extreme climates and harsh workshop environments without frequent maintenance.

- Flexible Installation and Easy System Integration

It supports multiple installation methods such as din rail and 19 – inch rack mounting, which is suitable for different control cabinet layouts. It is compatible with both 200 series and compact 200 series baseplates of the I/A Series. It can seamlessly connect with the I/A Series DCS database and support HART universal commands, which reduces the difficulty of system configuration and shortens the integration cycle.

Application Scenarios

- Petrochemical Industry

It is installed in oil refineries and chemical plants, connected with HART – compatible pressure, temperature and flow sensors on reactors, distillation towers and transmission pipelines. It collects parameters such as material reaction temperature and pipeline pressure in real time and transmits equipment diagnostic data to the DCS. The control system adjusts the opening of valves and the speed of pumps according to the data to ensure the safety and efficiency of the production process.

- Power Industry

It is deployed in coal – fired, gas – fired and nuclear power plants, matching with HART temperature transmitters on boilers and pressure sensors on steam turbines. It monitors key parameters such as boiler flue gas temperature and steam pressure, and sends the data to the central control system. It helps operators adjust fuel supply and cooling system operation in time to avoid equipment damage caused by parameter anomalies and ensure stable power generation.

- Water and Wastewater Treatment Industry

It is applied in water treatment plants, connected with HART water quality sensors and flow meters in water intake, filtration and disinfection links. It collects data such as pollutant concentration, water flow and pH value. The control system adjusts the dosage of disinfectants and the operation of water pumps based on the data to ensure that the treated water meets the discharge or reuse standards.

- Pharmaceutical Industry

It is used in pharmaceutical production lines involving chemical synthesis and drug preparation. It connects with HART temperature and pressure sensors on reaction kettles and concentration sensors in mixing tanks. It ensures accurate collection of process parameters in the drug production process, and helps the production system strictly follow GMP standards. It maintains the stability of drug quality and improves the qualification rate of finished products.

- Food and Beverage Industry

It is integrated into food processing lines such as beverage blending and dairy pasteurization. It is connected with HART temperature and pressure sensors on pasteurizers and filling equipment. It monitors parameters such as pasteurization temperature and filling pressure in real time. It prevents unqualified products caused by process parameter deviations and guarantees the safety and consistency of food and beverage products.

Reviews

There are no reviews yet.