Product Short Description

Technical Specifications

- Communication Interfaces:

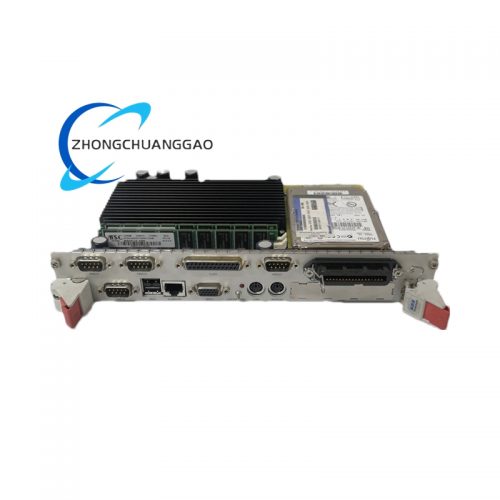

- Ethernet Ports: RJ45 interface for 10BASE-T Ethernet connection, supporting TCP/IP protocol for communication with process control and other automation systems.

- Serial Ports: RS232, RS422, and RS485 serial communication options, supporting Modbus RTU/ASCII protocols for flexible integration with various devices.

- Supported Protocols:

- Modicon Modbus Protocol: Via serial communication.

- Modbus/TCP Protocol: A variant of serial Modbus for TCP/IP Ethernet communication.

- Proprietary Bently Nevada Protocol: For communication with 3500 framework configuration and data acquisition software packages.

- Power Consumption: Typically 5.0 watts for Modbus RS232/RS422 I/O modules, and 5.6 watts for Modbus RS485 I/O modules.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments with appropriate temperature and humidity ratings.

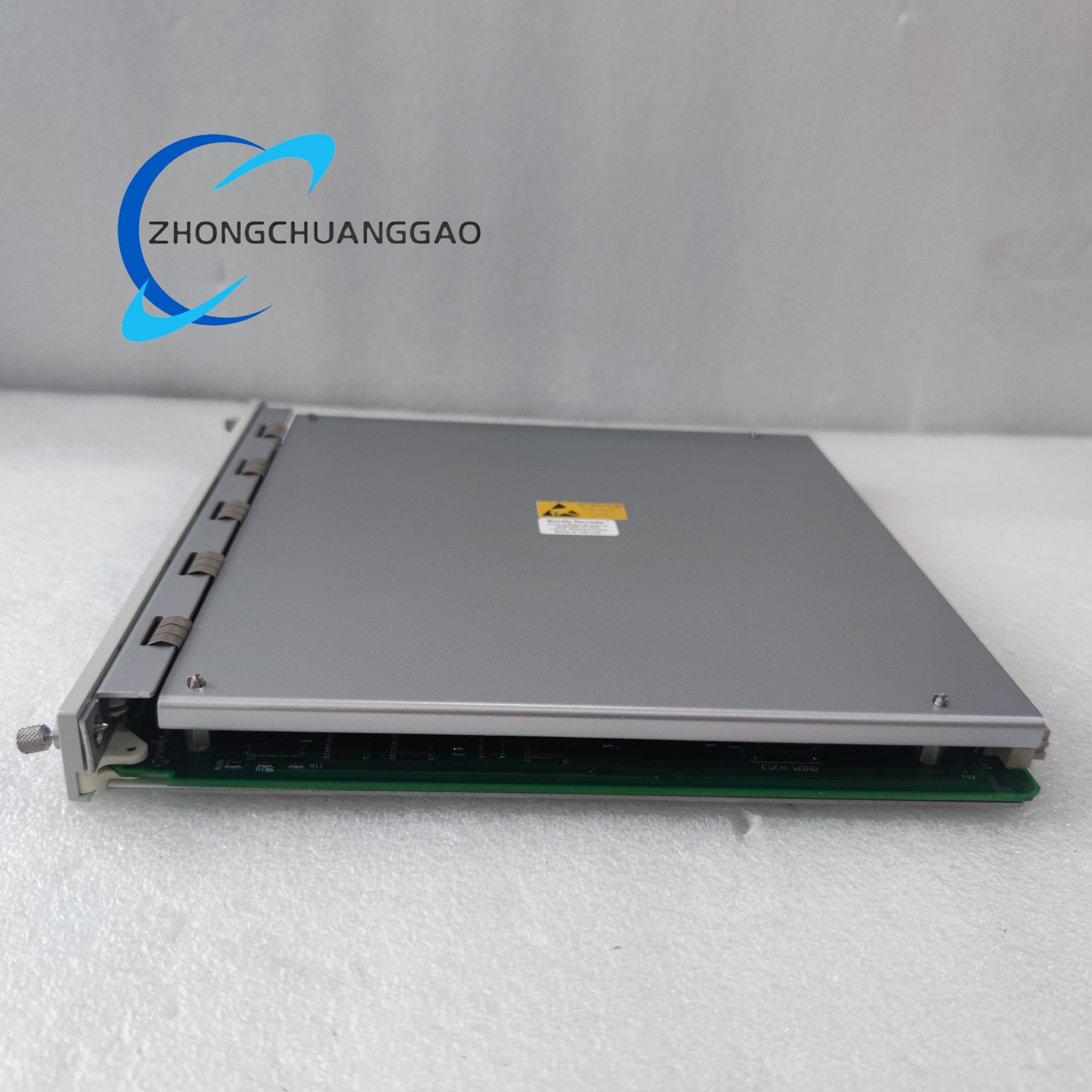

- Dimensions and Weight: Compact and lightweight design for easy installation in 19-inch racks.

Description

Key Features

- High Reliability: Built to operate continuously in demanding industrial settings, ensuring uninterrupted data communication and system monitoring.

- Flexible Communication Options: Supports multiple communication interfaces and protocols, enabling easy integration with a wide range of devices and systems.

- Real-Time Data Transmission: Capable of transmitting real-time monitoring data, including vibration, temperature, displacement, and other critical parameters, from the 3500 system to other systems for remote monitoring and diagnosis.

- Configurable Modbus Registers: Provides configurable Modbus registers that offer the same functionality as initial value registers, enhancing flexibility and customization.

- High-Speed Data Acquisition: Utilizes a high-speed internal network to collect information from other modules in the rack, including timestamped current measurements, module status, and current alarm status.

- Status Indicators: LED indicators (e.g., OK LED and TX/RX LED) on the front panel display the device’s operational status and communication status, facilitating troubleshooting and maintenance.

- Easy Configuration: Can be easily configured and programmed using 3500 framework configuration software.

- Security: System configuration is protected by software passwords to prevent unauthorized changes or tampering, ensuring system security.

Application Scenarios

- Power Generation: Used in power plants to monitor the health of turbines, generators, and other critical equipment, improving operational efficiency and preventing equipment failures.

- Oil and Gas: Real-time monitoring of rotating equipment in oil and gas facilities, ensuring safe and efficient operation while preventing costly downtime.

- Petrochemical Industry: Monitors compressors, pumps, and other rotating machinery in petrochemical plants, providing essential data for operation and maintenance personnel.

- Metallurgical Industry: Provides continuous monitoring for motors, gearboxes, and other equipment in metallurgical processes, aiding in preventive maintenance and reducing downtime.

- Manufacturing: Integrates with PLC, DCS, SCADA, and HMI systems in large factories to monitor and control production processes, enhancing productivity and quality.

- Transportation: Used in rail transit and marine applications to monitor the status of critical equipment, ensuring safety and reliability.

Reviews

There are no reviews yet.