Product Short Description

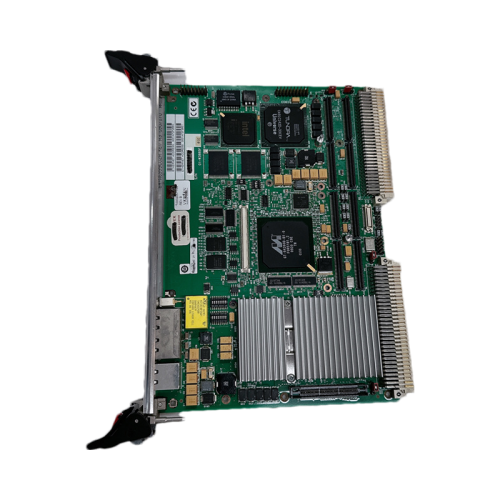

- Product Name

- 4-Channel Vibration Monitoring I/O Module for Bently Nevada 3500 Series Machinery Protection System

- Product Introduction

This module is a specialized input/output component designed exclusively for Bently Nevada’s 3500 series machinery protection systems. It serves as a core part of the system’s non-contact vibration monitoring architecture, focusing on capturing and processing vibration and position signals from rotating machinery. It accepts input signals from accelerometers and proximity sensors, converts the analog signals into measurable data, and compares them against user-programmed alarm thresholds. The module complies with industry standards such as API 670 and API 618, and holds certifications including ATEX, CSA, and CE to meet the requirements of hazardous industrial environments. It integrates seamlessly with the 3500 series rack and communicates smoothly with System 1 software, enabling predictive maintenance through real-time data analysis. It acts as a critical safeguard for detecting faults like bearing wear, misalignment, and imbalance in key machinery, ensuring continuous and reliable operation in various industrial sectors.

Description

- Technical Specifications

- Channel and Sensor Parameters: Features 4 independent monitoring channels. It is compatible with accelerometers with a standard sensitivity of 10 mV/g and also works with proximity sensors to realize vibration and position measurement.

- Measurement Performance: Operates within a frequency range of 10 Hz to 10 kHz. It achieves a data sampling rate of up to 20 kHz and a data acquisition rate of 512 Hz, with an input range of ±100 mV, ensuring high-resolution capture of vibration signal details.

- Power and Communication: Supports multiple communication interfaces including Ethernet (10/100 BaseT), serial ports, and CAN bus. It also complies with communication protocols such as Modbus and Ethernet/IP to achieve seamless connection with various industrial control systems.

- Physical Dimensions: Measures 200 mm × 150 mm × 100 mm and has a net weight of 2.0 kilograms. The compact size facilitates easy installation in the 3500 series rack without occupying excessive space.

- Environmental Adaptability: Boasts an IP67 enclosure protection rating. It operates stably within a temperature range of -40°C to +85°C and can be stored in an environment ranging from -55°C to +90°C, adapting to harsh working conditions with large temperature fluctuations and dust.

- Function Features

- High-Precision Multi-Parameter Monitoring: Specializes in accurate vibration and position measurement of rotating machinery. It processes collected signals via digital signal processing technology to improve signal quality, and can assist in monitoring additional physical quantities such as temperature and pressure when paired with matching sensors.

- Customizable Alarm Thresholds: Supports configuration of up to 16 alarm thresholds. Users can set personalized warning and trip thresholds according to different machinery operating standards. Once the measured data exceeds the set range, the module immediately triggers corresponding alarm prompts.

- Built-in Data Logging Capacity: Has an internal data logging function that can store up to 100,000 data points. The stored historical data can be retrieved and analyzed later, providing a reliable data basis for troubleshooting the root causes of machinery faults and optimizing equipment operation parameters.

- Seamless System Integration: Connects smoothly with the 3500 series rack through the backplane. It can also communicate with upper-level management systems and predictive maintenance software like System 1, enabling remote monitoring and data trending analysis for users.

- Strong Fault Tolerance and Reliability: Adapts to the 3500 series’ redundant configuration design, supporting configurations such as dual redundant power supplies and triple modular redundancy. This ensures that the monitoring function remains uninterrupted even if a single component malfunctions, enhancing the overall stability of the protection system.

- Application Scenarios

- Power Generation Industry: Deployed in thermal, hydroelectric, and nuclear power plants to monitor the operating status of steam turbines, gas turbines, and generators. It promptly detects vibration abnormalities caused by rotor imbalance or bearing damage, triggering alarms or shutdown procedures to prevent large-scale power outages.

- Oil and Gas Industry: Installed on offshore drilling rigs, pipeline compressors, and gas processing equipment. It withstands corrosive and high-vibration marine environments, monitoring vibration of drill strings and compressors to avoid equipment failures during oil and gas extraction and transportation.

- Petrochemical Industry: Applied to centrifugal compressors, reaction tower auxiliary pumps, and gearboxes in chemical plants. It operates stably in hazardous areas with flammable and explosive gases, detecting early fault signals to reduce risks of leaks and explosions caused by equipment breakdowns.

- Metallurgical and General Manufacturing Industry: Used to monitor large motors, fans, and rolling mill equipment in metallurgical plants and manufacturing workshops. It identifies vibration faults in machinery during high-load operation, helping maintenance personnel perform targeted maintenance and reducing production downtime.

- Marine and Offshore Industry: Certified by DNV and Class NK, it is suitable for marine propulsion systems and offshore platform auxiliary machinery. It monitors vibration of marine turbines and pumps under harsh marine conditions, ensuring the safe navigation of ships and the stable operation of offshore facilities.

Reviews

There are no reviews yet.