Product Short Description

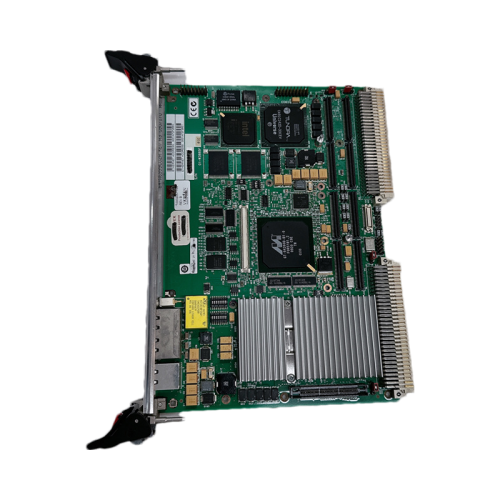

- Product Name

- 16-Channel Relay Output Module for Bently Nevada 3500 Series Machinery Protection System

- Product Introduction

This module is a full-height core component tailored for Bently Nevada’s 3500 series machinery protection systems, functioning as a critical bridge between the system’s monitoring units and external industrial control devices. It integrates 16 independent relay channels to deliver dedicated relay output services for large rotating and reciprocating machinery. The module receives real-time status signals such as vibration, temperature, and speed from other monitoring modules in the 3500 series via the rack backplane. It then translates these signals into actionable relay operations based on pre-programmed logic, triggering alarms, emergency shutdowns, or interlocking control for external equipment. It complies with the American Petroleum Institute’s API 670 standard, which is a benchmark for machinery protection systems. Its epoxy-sealed structural design ensures stable performance in harsh industrial settings, and it can be flexibly installed in any slot on the right side of the 3500 series rack interface module, providing strong support for the safe and continuous operation of critical industrial machinery.

Description

- Technical Specifications

- Relay Core Parameters: Equipped with 16 single-pole double-throw relays. Each relay contact has a service life of 100,000 operation cycles at full load. A 250Vrms arc suppressor is installed as a standard configuration to prevent electrical arc damage to contacts.

- Power Consumption: Operates with a typical power consumption of 5.8 watts, which matches the power distribution specifications of the 3500 series rack and ensures efficient energy use during long-term operation.

- Environmental Adaptability: Works stably within an operating temperature range of -30°C to +65°C. The storage temperature range extends from -40°C to +85°C. It can operate normally in an environment with 95% non-condensing humidity, and its epoxy-sealed structure enhances resistance to dust and moisture.

- Physical Specifications: The physical dimensions measure 2.6 centimeters ×25.6 centimeters ×24.4 centimeters, with a net weight of 0.4 kilograms. The compact and lightweight design allows for easy integration into the 3500 series rack without occupying excessive space.

- Panel Indicator: Features front-panel light-emitting diodes that stay illuminated when the module operates normally, enabling on-site personnel to quickly confirm the module’s working status at a glance.

- Function Features

- Independent Programmable Logic: Each of the 16 relay channels can be programmed independently. It supports AND and OR logic configurations, allowing users to establish complex cause – and – effect relationships between input signals and relay outputs to meet diverse control requirements of different industrial scenarios.

- Integrated Alarm Drive Logic: Every relay is built with integrated alarm drive logic. It can directly access alert and danger status signals from the monitoring system, and immediately trigger corresponding relay actions once abnormal parameters are detected, ensuring rapid response to equipment faults.

- Flexible Rack Compatibility: It can be installed in any slot on the right side of the 3500 series rack interface module. Multiple such modules can be deployed simultaneously according to the scale of the monitoring system, realizing expansion of relay output channels to adapt to large – scale machinery groups.

- Compliance with Industrial Standards: It meets the API 670 standard for machinery protection systems. This compliance ensures that the module can seamlessly integrate into industrial systems that have strict requirements for equipment reliability and safety, eliminating compatibility and compliance risks for users.

- Application Scenarios

- Power Generation Industry: Deployed in thermal, hydro, and nuclear power plants to monitor key equipment including steam turbines, generators, and coal millers. It triggers timely shutdowns or auxiliary equipment startup when abnormal vibration or overheating occurs, preventing major power generation interruptions.

- Oil and Gas Industry: Installed on offshore drilling rigs, pipeline compressors, and natural gas processing plants. It controls emergency depressurization valves and pump interlock systems in response to faults such as bearing wear and rotor imbalance, safeguarding operations in explosive and corrosive environments.

- Chemical Industry: Applied to chemical reaction kettles, agitators, and transfer pumps in chemical plants. It links with temperature and pressure monitoring modules to activate isolation valves or fire suppression systems when process parameters deviate, avoiding leakage and explosion accidents.

- Metallurgical Industry: Used in steel mill rolling mills, blast furnace blowers, and air separation compressors. It operates reliably in high – temperature and dusty environments, triggering lubrication system adjustments or production line pauses when equipment vibration exceeds thresholds, reducing equipment wear and failure rates.

- General Manufacturing: Integrated into production lines with large motors, gearboxes, and centrifugal pumps. It monitors the operating status of these key transmission and power components, outputs alarm signals or stops related processes when faults are detected, ensuring the stability of the entire production line and reducing unplanned downtime.

Reviews

There are no reviews yet.