Product Short Description

- Product Name

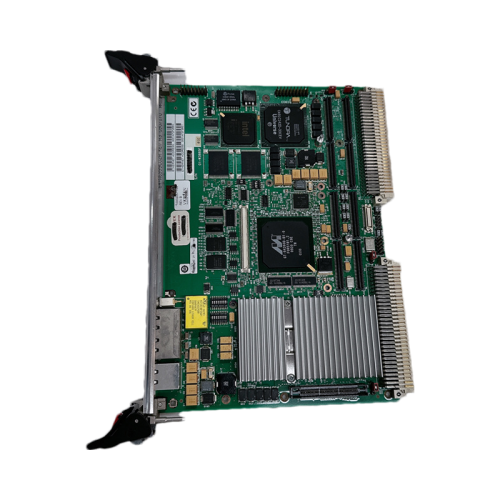

- Universal Equipment Monitor Module for Bently Nevada 3500 Series Machinery Monitoring System

- Product Introduction

This module is a cost-effective universal equipment monitoring component under Bently Nevada’s 3500 series. It is specifically designed to continuously monitor and protect various industrial machinery and processes. It integrates multi-channel input and output functions, being compatible with multiple types of sensors and temperature measurement elements. It can connect with different industrial control systems through multiple communication methods and supports on-site configuration and remote operation. The module stores configuration information in non-volatile memory to avoid data loss due to power outages. It can work independently with an optional display/keyboard or integrate into the overall 3500 series monitoring system, making it an ideal solution for general machinery that requires reliable monitoring without high costs.

Description

- Technical Specifications

- Input Capabilities: It is equipped with four sensor inputs and four temperature inputs. The sensor inputs support 2-wire and 3-wire accelerometers, velocity sensors, and proximity sensors. Each temperature input is compatible with E, J, K, and T-type thermocouples, as well as 2-wire or 3-wire RTDs. It uses a 24-bit ADC conversion to ensure high-precision data collection.

- Output Performance: It provides six relay outputs, four 4-20 mA recorder outputs, and one dedicated buffer output. The relay contacts have programmable switching capabilities, and the dedicated buffer output can transmit signals from each sensor input without signal distortion.

- Communication Parameters: It supports Ethernet and software-configurable RS232/485 serial ports. It is compatible with Ethernet/IP and Profinet protocols, and the Modbus gateway option enables direct communication with DCS, SCADA, PLC, and System 1 software.

- Physical Indicators: It weighs 2.5 kilograms and has dimensions of 20 centimeters × 25 centimeters × 30 centimeters. The design conforms to the standard installation specifications of the 3500 series, facilitating integration into existing racks.

- Storage and Operation: It has a 200-entry event list to record equipment operation status and fault information. The non-volatile memory permanently stores configuration files. It supports connection with an optional display/keyboard, which can be installed up to 75 meters away from the module.

- Function Features

- Multi-Type Sensor Compatibility: The module’s sensor inputs and temperature inputs match a wide range of common industrial sensing devices. This compatibility eliminates the need for additional signal converters, reducing equipment investment and simplifying the connection between the module and different types of monitored machinery.

- Flexible Output Configuration: The six programmable relay outputs can be set to switch according to the normal, alarm, and dangerous states of a single channel or a combination of channels. The four 4-20 mA recorder outputs can transmit data from any variable of any channel, meeting diverse data recording and control linkage needs.

- Seamless Industrial Network Integration: It supports multiple mainstream industrial communication protocols and Modbus gateways. It can smoothly access various industrial control systems, realizing real-time transmission of static variables, equipment status, and event lists, which helps to build a unified industrial monitoring platform.

- Convenient Configuration and Maintenance: Users can download configuration files to the module via Ethernet through a PC. The optional remote display/keyboard allows on-site viewing of channel data and minor configuration adjustments. The non-volatile memory ensures that configuration information is not lost, and the event list provides a basis for fault tracing and maintenance.

- Secure and Stable Data Transmission: It is equipped with network redundancy and fault-tolerance functions. When partial network components fail, it can maintain continuous data transmission. The optional encrypted communication function prevents data tampering or theft during transmission, ensuring the security and integrity of monitoring data.

- Application Scenarios

- General Manufacturing Industry: It is installed on production lines of common machinery such as conveyor belts, small motors, and pumps in light industry and heavy manufacturing plants. It monitors vibration and temperature parameters, triggering alarms promptly when abnormalities occur to avoid production line shutdowns caused by equipment failures.

- Food and Beverage Industry: It is used to monitor the operating status of mixing equipment, conveying pumps, and refrigeration compressors in food processing workshops. It adapts to the clean and low-noise environment of the industry and uses stable temperature monitoring to ensure that production equipment operates within the required temperature range.

- Water Treatment Industry: It is deployed in water supply and sewage treatment plants to monitor water pumps, aerators, and other key equipment. It connects with the SCADA system through the Modbus gateway to realize centralized monitoring of equipment operation, ensuring the continuity of water treatment processes and the stability of water supply quality.

- Light Chemical Industry: It is applied to small and medium-sized reaction kettles, agitators, and pipeline pumps in chemical plants that do not involve ultra-high pressure and ultra-high temperature. It monitors equipment vibration and bearing temperature, providing early warning of potential faults and ensuring the safe operation of small-scale chemical production processes.

- Building Automation and Logistics: It is integrated into logistics warehouse conveyor systems and building central air-conditioning circulating pumps. It monitors the operating status of these supporting equipment. Its cost-effectiveness and simple configuration make it suitable for large-scale deployment in scenarios that require multi-point monitoring but have limited budget.

Reviews

There are no reviews yet.