Product Short Description

Its multi-segment part number decodes the targeted configuration: “01” (first segment) confirms a single-channel design, “03” (second segment) emphasizes optimized performance for vibration acceleration measurement (the primary differentiator from standard or displacement-focused modules), and the subsequent “00” segments indicate baseline electrical interfaces, mechanical packaging, and no optional add-ons. Engineered to excel in detecting high-frequency vibration anomalies, this module converts raw acceleration, velocity, and displacement signals from sensors into calibrated, industry-standard outputs for seamless integration with DCS, PLC, and dedicated monitoring platforms. It is specifically tailored to work with Bently’s 330851 piezoelectric acceleration sensors (the primary sensor for high-frequency measurement) and other 3300 series sensors, while supporting compatible third-party devices. Adhering to global industrial standards (IEC, UL, CSA), the module features enhanced signal conditioning for high-frequency acceleration data, robust EMI/RFI shielding, and a compact form factor for 3500 chassis integration. By delivering accurate, real-time acceleration and complementary vibration data, this module enables early detection of faults like bearing fatigue, gear tooth wear, and resonant frequency issues—making it critical for protecting high-speed rotating assets across aerospace, automotive, power generation, and manufacturing industries.

Description

Technical Specifications

-

Part Number: 350005-01-03-00-00-00

-

Module Type: Single-channel vibration transmitter (acceleration-optimized, analog output, signal conditioning)

-

Primary Measurement Parameters: Vibration acceleration (peak, optimized); selectable velocity (RMS) and displacement (peak-to-peak)

-

Measurement Ranges (Configurable): Acceleration: 0–100 g peak (default); 0–10/20/50 g peak (user-selectable via DIP switches)

-

Velocity: 0–50 mm/s RMS

-

Displacement: 0–10 mm peak-to-peak

Frequency Response (Enhanced for Acceleration): Acceleration: 5 Hz – 20,000 Hz (±2 dB) – optimized for high-frequency vibration

Velocity: 1 Hz – 2,500 Hz (±3 dB)

Displacement: 0.5 Hz – 500 Hz (±3 dB)

Input Compatibility (Acceleration-Focused): Acceleration Sensors: Bently 330851 (piezoelectric, charge/voltage mode) – primary for acceleration

Proximity Probes: Bently 3300 XL (8 mm, 11 mm, 14 mm tip diameters)

Velocity Transducers: Bently 330850 (moving-coil type)

Input Signal Type: Piezoelectric charge (10 pC/g to 1000 pC/g, primary), differential voltage (±10 V DC), eddy-current (proximity probe)

Output Configurations: Analog: 2x isolated 4–20 mA DC channels (1 primary, 1 redundant); 1000 Ω max load per channel

Status Outputs: 2x dry contacts (Form A) – 1 for sensor fault, 1 for acceleration threshold alert (1 A @ 250 V AC / 30 V DC each)

Power Supply: DC Input: 24 V DC ±20% (nominal 24 V DC); galvanically isolated

Power Consumption: ≤ 4 W per module (includes internal charge amplifier)

Operating Environment: Temperature: -40 °C to +70 °C (-40 °F to +158 °F)

Humidity: 5%–95% RH (non-condensing)

Altitude: Up to 2,000 meters (6,562 feet)

Shock & Vibration: IEC 60068-2-27 (shock: 50 g, 11 ms); IEC 60068-2-6 (vibration: 10 g, 10–2000 Hz)

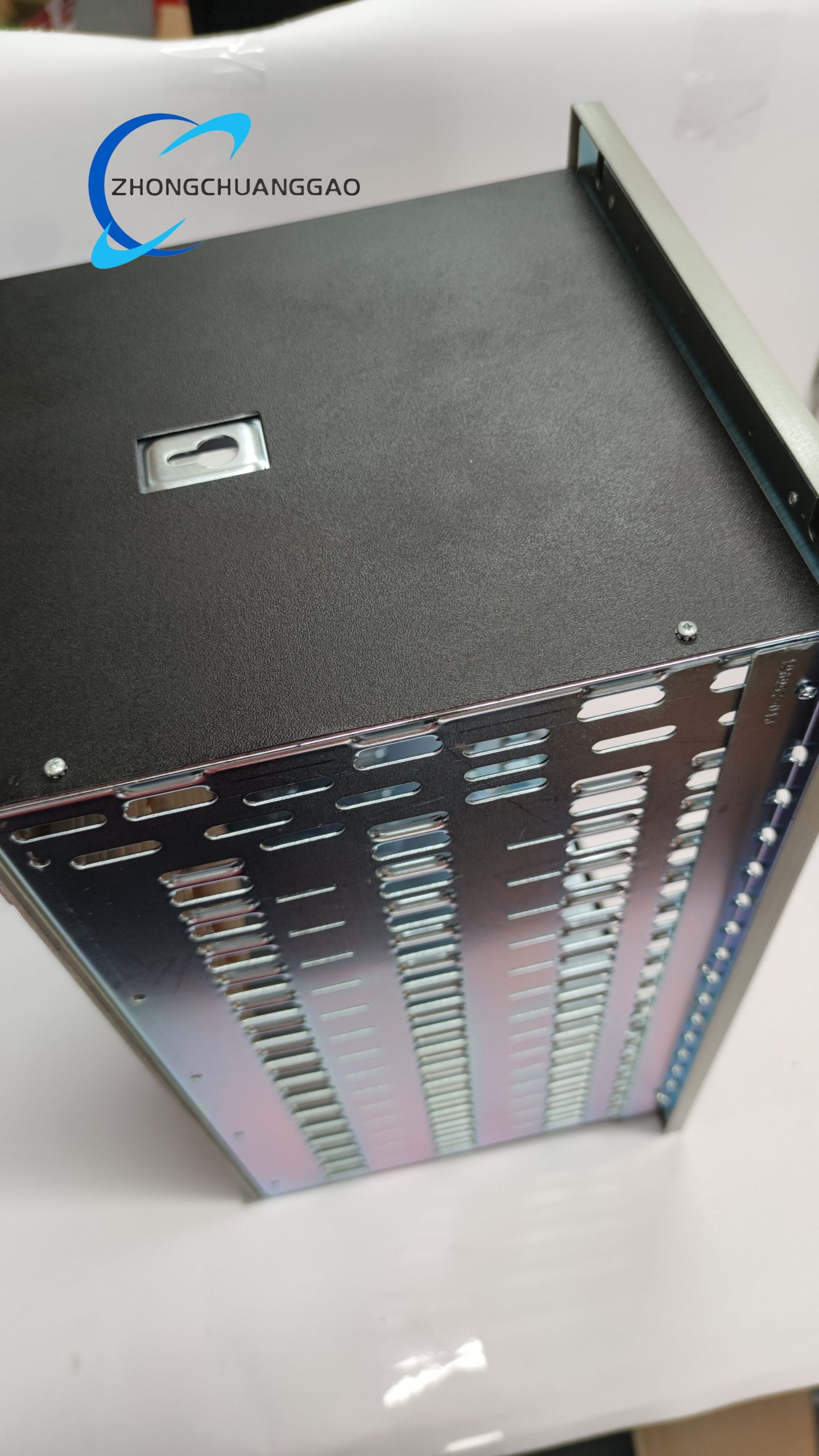

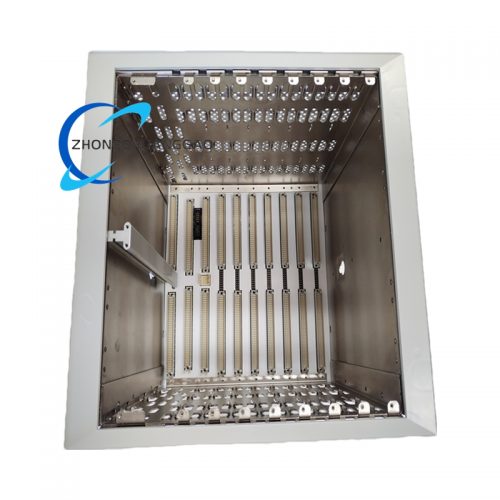

Mechanical Specifications: Housing: Aluminum alloy, powder-coated (IP20 front panel; IP40 when installed in 3500 chassis)

Mounting: 3500 system chassis (19-inch rack mount; 1 slot per module)

Dimensions (per module): 15.2 mm (width) x 152.4 mm (height) x 203.2 mm (depth)

Weight: 0.3 kg (0.66 lbs)

Accuracy (Enhanced for Acceleration): Acceleration: ±0.15% of full-scale (at 25 °C ±5 °C, 100 Hz reference)

Velocity: ±0.25% of full-scale

Displacement: ±0.25% of full-scale

Resolution: 0.0005 g (acceleration mode); 0.001 mm/s RMS (velocity); 0.001 mm (displacement)

Internal Charge Amplifier: Built-in, gain-adjustable (10–1000 V/g) charge amplifier for direct connection to piezoelectric sensors, eliminating the need for external signal conditioning

EMI/RFI Immunity: Complies with IEC 61000-4-2 (ESD: ±8 kV contact, ±15 kV air), IEC 61000-4-3 (radiated: 200 V/m), IEC 61000-4-6 (conducted: 10 Vrms)

Calibration: Factory-calibrated with NIST-traceable standards; field recalibration via Bently 3500 Calibration Kit (P/N 350095-01)

Certifications: UL 61010-1, CSA C22.2 No. 61010-1, CE (EN 61326-1), ATEX/IECEx (optional for Zone 1/2 hazardous areas)

Function Features

-

Acceleration-Optimized Signal Processing: Enhanced hardware includes a high-bandwidth charge amplifier and specialized firmware, delivering ±0.15% accuracy across 5 Hz–20,000 Hz—critical for detecting high-frequency faults like bearing rolling element fatigue, gear tooth impact, and resonant vibrations. This outperforms standard modules in capturing subtle, high-speed anomalies that precede machinery failure.

-

Built-In Charge Amplifier: The integrated, gain-adjustable charge amplifier allows direct connection to piezoelectric acceleration sensors, eliminating the need for external signal conditioning equipment. This reduces installation complexity, minimizes signal loss, and lowers overall system costs compared to setups requiring separate amplifiers.

-

Single-Channel Targeted Monitoring: Dedicated single-channel design focuses processing power on critical high-speed components (e.g., turbine blades, motor bearings, gearbox pinions), avoiding cross-channel interference. Ideal for retrofitting into existing 3500 systems where specific assets demand precise acceleration monitoring without full system upgrades.

-

Multi-Parameter Measurement Flexibility: While optimized for acceleration, users can switch between acceleration, velocity, and displacement via front-panel DIP switches. This adaptability supports diverse applications—using acceleration for high-speed motors, velocity for pumps, and displacement for slow-speed shafts—reducing inventory of specialized modules.

-

Dual Isolated Analog Outputs: Two independent 4–20 mA outputs provide redundant signal transmission to primary DCS and secondary monitoring systems. Galvanic isolation prevents ground loops and signal corruption, essential for safety-critical applications like aerospace test stands and power generation turbines.

-

Dual Status Outputs for Precise Alerts: Separate dry contacts for sensor faults and acceleration threshold alerts enable granular troubleshooting. The acceleration threshold can be configured to trigger warnings at user-defined levels (e.g., 90% of manufacturer’s fatigue limits), allowing proactive maintenance before component failure.

-

Advanced EMI/RFI Shielding: Module-level EMI filtering, shielded input terminals, and twisted-pair signal paths protect against electromagnetic interference from high-frequency drives, radar systems, and industrial communication networks. This ensures stable measurements in electrically noisy environments like automotive assembly lines and aerospace facilities.

-

Seamless 3500 System Integration: Designed to slot into Bently’s 3500 chassis, the module integrates with 3500 display modules, alarm logic solvers, and communication modules (Ethernet/Modbus). This modularity allows scaling from single-point monitoring to full machinery protection systems, leveraging existing infrastructure and reducing capital expenditure.

-

Extreme Environment Durability: -40 °C to +70 °C temperature range and robust shock/vibration resistance enable reliable operation in arctic aerospace test facilities, desert power plants, and high-vibration manufacturing lines. The module maintains calibration and performance in conditions that degrade standard monitoring devices.

-

User-Friendly On-Site Configuration: Front-panel DIP switches for range selection, parameter switching, and gain adjustment, paired with LED indicators (power, signal, fault, threshold alert), enable on-site setup without specialized software. Technicians can reconfigure the module in minutes, minimizing downtime during maintenance or asset changes.

Application Scenarios

-

Aerospace (Jet Engine Test Stands): Installed in jet engine test facilities to monitor high-frequency vibration (5 Hz–20,000 Hz) in turbine blades and compressor stages. The built-in charge amplifier connects directly to Bently 330851 acceleration sensors, delivering ±0.15% accuracy for compliance with aerospace certification standards. Dual outputs send data to test cell DCS and data acquisition systems.

-

Automotive (High-Speed Motor Assemblies): Deployed in electric vehicle (EV) manufacturing plants to monitor acceleration in high-speed traction motors and gearboxes. The module detects bearing fatigue and gear tooth wear via high-frequency vibration analysis, reducing warranty claims and ensuring motor reliability. Integration with factory MES systems supports predictive maintenance.

-

Power Generation (Gas Turbine Combustors): Used in combined-cycle power plants to monitor combustion-induced vibration in gas turbine combustors. The high-frequency response captures resonant vibrations that indicate fuel injector wear or flame instability. Acceleration threshold alerts trigger adjustments to fuel flow, preventing catastrophic turbine damage.

-

Manufacturing (CNC Machining Centers): Installed in aerospace and medical device manufacturing facilities to monitor spindle acceleration in high-precision CNC mills and lathes. The module detects tool wear and spindle imbalance via subtle acceleration changes, reducing part defects and extending tool life. Easy gain adjustment supports different machining materials (titanium, aluminum).

-

Oil & Gas (High-Speed Centrifuges): Deployed in offshore oil platforms and refineries to monitor acceleration in high-speed oil/water separation centrifuges. Optional ATEX/IECEx certification allows use in Zone 1 hazardous areas. The module detects bearing degradation and rotor imbalance, preventing centrifuge failure and production downtime.

-

Marine (Propulsion Motor Bearings): Installed in naval and commercial ships to monitor acceleration in propulsion motor bearings and reduction gears. The module’s wide temperature range withstands engine room heat, while EMI/RFI shielding resists interference from shipboard radar and communication systems. Status outputs integrate with ship safety alarms.

-

Industrial Machinery (High-Speed Pumps): Used in petrochemical and pharmaceutical plants to monitor acceleration in high-speed process pumps (3,600–10,000 RPM). The module detects cavitation and impeller wear via high-frequency vibration, allowing maintenance before pump failure disrupts critical processes. Compatible with Bently 330851 sensors for long-term reliability.

-

Renewable Energy (Wind Turbine Gearboxes): Deployed in wind farms to monitor acceleration in wind turbine gearboxes. The module detects planetary gear wear and bearing fatigue via high-frequency vibration analysis, a leading cause of wind turbine downtime. Data integrates with wind farm SCADA systems for remote monitoring and maintenance scheduling.

-

Medical (MRI Cooling Pumps): Installed in hospitals to monitor acceleration in high-speed cooling pumps for MRI machines. The module’s low electromagnetic interference (EMI) profile prevents disruption to MRI imaging, while acceleration monitoring ensures pump reliability—critical for maintaining MRI operational availability.

Reviews

There are no reviews yet.