Product Short Description

The part number’s encoded details define its core configuration: “065” specifies a 65 mm/s RMS vibration velocity measurement range, “01” indicates a single-channel design for focused monitoring, and “05” denotes a factory-fitted 5-meter integral cable that simplifies installation. Unlike basic monitoring devices, this unit integrates signal conditioning, real-time data processing, configurable alarms, and a pre-terminated cable into a compact, rugged enclosure—eliminating the need for separate wiring and reducing potential signal loss points. It is optimized to pair seamlessly with Bently Nevada’s 330850 velocity transducers and 330851 acceleration transducers, while also supporting compatible third-party sensors. Manufactured to meet global industrial standards (IEC, UL), the monitor features an IP65-rated aluminum housing, robust EMI/RFI shielding, and user-friendly front-panel configuration. By providing accurate vibration insights, fast alarm responses, and hassle-free installation, it enables early detection of faults like bearing wear, rotor misalignment, and gear degradation, minimizing unplanned downtime and supporting predictive maintenance across power generation, oil & gas, manufacturing, and marine industries.

Description

Technical Specifications

-

Part Number: 330930-065-01-05

-

Device Type: Single-channel vibration monitor (velocity/acceleration/displacement) with integral cable

-

Primary Measurement Parameter: Vibration velocity (RMS); selectable acceleration (peak) and displacement (peak-to-peak)

-

Measurement Ranges (Configurable): Velocity: 0–65 mm/s RMS (default)

-

Acceleration: 0–60 g peak

-

Displacement: 0–6 mm peak-to-peak

Frequency Response: Velocity: 1 Hz – 2,500 Hz (±3 dB)

Acceleration: 2 Hz – 10,000 Hz (±3 dB)

Displacement: 0.5 Hz – 500 Hz (±3 dB)

Integral Cable Specifications: Length: 5 meters (16.4 feet)

Insulation: FEP (Fluorinated Ethylene Propylene) – oil, chemical, and heat resistant

Shielding: 95% coverage braided tinned copper (EMI/RFI protection)

Connector: Bently proprietary 8-pin bayonet connector (pre-terminated, water-sealed)

Cable Rating: -40 °C to +125 °C (-40 °F to +257 °F) operating temperature

Input Compatibility: Velocity Transducers: Bently 330850 (8 mm, 11 mm probes)

Acceleration Transducers: Bently 330851 (piezoelectric, charge-mode/voltage-mode)

Input Signal Type: Differential voltage (±10 V DC) or charge (10 pC/g to 1000 pC/g)

Output Configurations: Analog: 4–20 mA DC (isolated, 500 Ω max load)

Digital: RS485 (Modbus RTU protocol, baud rates 9600–115200)

Alarm Relays: 2x Form C (SPDT) relays; 2 A @ 250 V AC / 30 V DC (high/low alarm)

Power Supply: DC Input: 18–32 V DC (nominal 24 V DC)

AC Input: 85–264 V AC, 50/60 Hz (optional)

Power Consumption: ≤ 5 W (DC supply); ≤ 7 W (AC supply)

Operating Environment: Temperature: -10 °C to +65 °C (14 °F to +149 °F)

Humidity: 10%–90% RH (non-condensing)

Altitude: Up to 2,000 meters (6,562 feet)

Mechanical Specifications: Housing: Aluminum alloy, powder-coated (IP65 ingress protection)

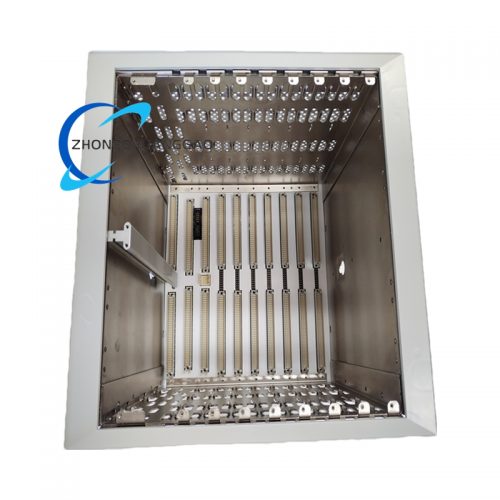

Mounting: 19-inch rack mount (1U height, 483 mm width)

Display: 2-line backlit LCD (16×2 characters), shows measurement value, unit, status

Controls: 4 tactile buttons (menu, up, down, enter)

Accuracy: ±0.3% of full-scale measurement (at 25 °C)

Resolution: 0.01 mm/s RMS (velocity mode); 0.001 g (acceleration mode); 0.001 mm (displacement mode)

EMI/RFI Immunity: Complies with IEC 61000-4-2 (ESD), IEC 61000-4-3 (radiated), IEC 61000-4-6 (conducted)

Response Time: < 80 ms (for alarm activation)

Certifications: UL 61010-1, CE (EN 61326-1), ATEX (optional for hazardous areas)

Function Features

-

Factory-Integrated 5-Meter Cable for Simplified Installation: The pre-terminated, FEP-insulated cable eliminates on-site wiring errors and reduces installation time by up to 40%. 95% copper shielding ensures noise-free signal transmission from sensor to monitor, critical for accurate measurements in high-electrical-noise environments like factory floors or power plants.

-

Extended 65 mm/s Velocity Range: Bridges the gap between standard low-range (0–50 mm/s) and high-range (0–100 mm/s) monitors, making it ideal for machinery with variable vibration profiles—such as centrifugal pumps, medium turbines, and industrial fans—that operate across mid-to-high vibration levels without needing multiple devices.

-

Tri-Parameter Measurement Flexibility: Users can switch between velocity (primary), acceleration, and displacement via the front panel, adapting to diverse machinery monitoring needs. This eliminates the cost of purchasing dedicated monitors for each parameter and simplifies system upgrades.

-

High Precision & Temperature Stability: ±0.3% accuracy and temperature-compensated circuitry ensure consistent readings across operating temperatures, preventing false alarms from environmental fluctuations. The 0.01 mm/s resolution captures subtle anomalies like incipient bearing fatigue before they escalate into failures.

-

Configurable Alarms with Diagnostic Clarity: Dual Form C relays support independent high/low alarm thresholds set via the LCD interface. The monitor distinguishes between vibration alarms, sensor faults, and power issues, providing clear diagnostic feedback to streamline troubleshooting.

-

Seamless Control System Integration: RS485 Modbus RTU connectivity enables integration with DCS (Siemens PCS 7, Emerson DeltaV), SCADA, and predictive maintenance software. The isolated 4–20 mA output ensures compatibility with legacy analog systems, supporting phased industrial upgrades.

-

Rugged IP65 Enclosure: Aluminum housing with IP65 protection resists dust, water spray, and mechanical impact, making it suitable for harsh environments—from offshore platforms and mining sites to petrochemical refineries.

-

User-Centric Operation: Backlit LCD and intuitive buttons allow on-site configuration without specialized software. Quick-access menus for range adjustment, alarm setting, and status checks reduce training requirements and maintenance time.

-

Sensor Fault Detection: Automatically identifies sensor disconnections, short circuits, and signal degradation, triggering a dedicated fault alarm to prevent unmonitored operation—a critical safety feature for mission-critical machinery.

Application Scenarios

-

Power Generation (Steam & Gas Turbines): Installed in turbine control rooms to monitor bearing vibration. The 5-meter cable reaches sensors mounted on turbine casings, while the 65 mm/s range accommodates startup/shutdown transients. High precision detects rotor misalignment and blade degradation, avoiding costly turbine outages.

-

Oil & Gas (Offshore Platforms & Pipeline Pumps): Deployed on offshore rigs and pipeline pump stations. The integral cable simplifies installation in tight spaces, and FEP insulation resists saltwater and hydrocarbon exposure. IP65 housing withstands harsh maritime conditions, while Modbus enables remote monitoring of distributed assets.

-

Petrochemical Refining (Catalytic Crackers & Agitators): Used to monitor vibration in catalytic cracker fans and reactor agitators. The tri-parameter capability tracks velocity (normal operation) and acceleration (high-frequency faults), complying with safety regulations. The pre-terminated cable reduces installation time in hazardous areas (with optional ATEX certification).

-

Manufacturing (CNC Machines & Robotic Lines): Installed in automotive/aerospace factories to monitor CNC mill and robotic arm vibration. The 5-meter cable reaches sensors on machine tools, and high resolution detects tool wear and spindle imbalance—reducing product defects and unplanned production stops.

-

Marine (Ship Propulsion & Auxiliary Systems): Deployed in ship engine rooms to monitor diesel engine and auxiliary pump vibration. The integral cable fits in compact engine compartments, and dual power supply options adapt to marine electrical systems. Rugged housing withstands shock from ship movement.

-

Mining (Crushers & Conveyor Drives): Used in coal/mineral mines to monitor crusher and conveyor motor vibration. The IP65 enclosure resists dust and water, while the 5-meter cable reaches sensors in remote mining areas. Sensor fault detection prevents unmonitored operation in isolated locations.

-

Renewable Energy (Wind Turbine Gearboxes): Installed in wind farm nacelles to monitor gearbox vibration. The integral cable simplifies installation 100+ meters above ground, and the 65 mm/s range accommodates variable wind-induced vibration. Modbus connects to wind farm management systems for predictive maintenance.

-

Water & Wastewater Treatment (Large Pumps): Deployed in municipal plants to monitor large pump vibration. The 5-meter cable reaches sensors on pump housings, and alarms trigger maintenance before failures cause process disruptions—ensuring continuous water treatment for urban populations.

Reviews

There are no reviews yet.