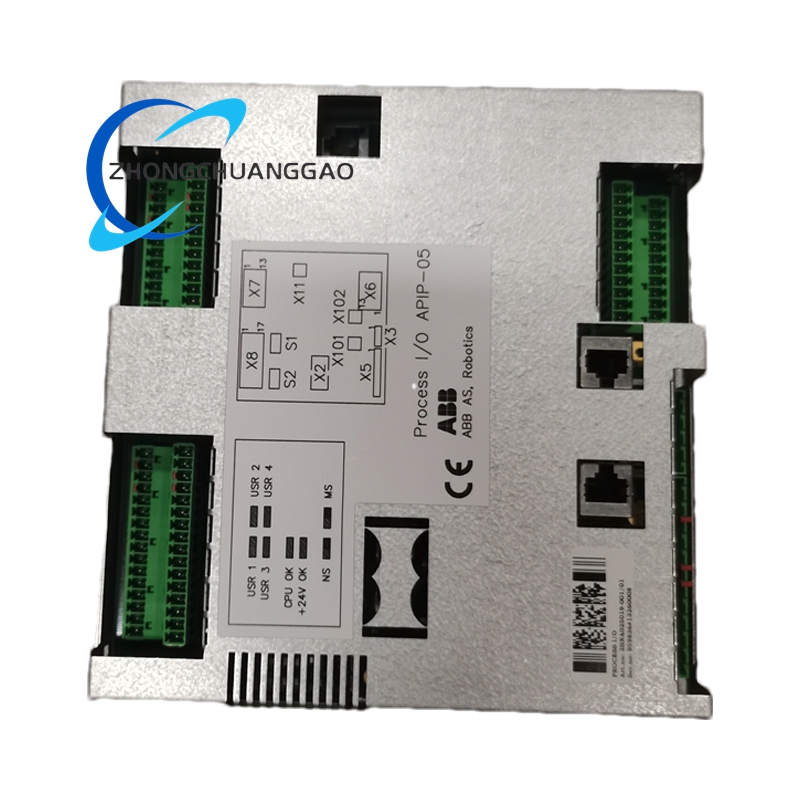

Product Short Description

Technical Specifications

- Processor: Intel® Core 2 Duo or equivalent high-speed CPU for real-time control.

- Memory: DDRⅡ SODIMM ×1, up to 2 GB system memory.

- Storage: Type II CF card slot for expandable storage.

- I/O Configuration:

- Digital outputs: 2 channels (PNP/NPN configurable, constant current ≤150 mA).

- Analog inputs: Supports 0–600 bar pressure measurement (0–8700 psi, 0–60 MPa).

- Communication ports: RS-232 ×3, RS-232/422/485 ×1, 10/100/1000Base-TX Ethernet ×2.

- Power Supply:

- DC input: 9–30 VDC (built-in DC-DC converter).

- AC input: 100–240 VAC @ 50–60 Hz (optional external adapter).

- Operating Conditions:

- Temperature: -25°C to +80°C (operation), -40°C to +100°C (storage).

- Humidity: Up to 95% non-condensing.

- Protection: IP65/IP67-rated enclosure for dust and water resistance.

- Mechanical Design:

- Dimensions: 214 mm (W) × 94.8 mm (H) × 237.8 mm (D).

- Weight: 5.63 kg.

- Mounting: Wall-mounted or rack-installed.

Description

Key Features

- High-Speed Digital Signal Processing: Enables rapid conversion and transmission of digital signals for precise control.

- Robust Design: Built with industrial-grade materials (stainless steel, PBT-GF30) to withstand vibrations, electromagnetic interference, and extreme temperatures.

- Flexible I/O Configuration: Supports customizable digital/analog inputs/outputs for diverse automation needs.

- Multi-Protocol Communication: Integrates Ethernet, RS-232/485, and Modbus/Profibus for seamless connectivity with PLCs, HMIs, and data acquisition systems.

- Safety Isolation: Electrical isolation between input signals and system components to prevent interference and protect equipment.

- Diagnostic Tools: Built-in self-testing, LED indicators (power/HDD), and programmable watchdog timers for proactive maintenance.

- Scalability: Easily expands with additional I/O modules, communication ports, or analog channels.

Functional Capabilities

- Real-Time Control: Executes complex logic and sequence control for robotic arms, conveyors, and valves.

- Data Acquisition: Collects sensor data (e.g., pressure, temperature) and processes it for monitoring.

- Communication Management: Facilitates protocol conversion and data exchange between networks.

- System Monitoring: Tracks device status, performance metrics, and alarms.

- Remote Access: Enables configuration and troubleshooting via secure network connections.

Application Scenarios

- Industrial Automation: Controls robotic arms, conveyor belts, and valves in manufacturing lines.

- Paint Spraying Systems: Manages paint flow, pressure, and nozzle activation in automotive and aerospace sectors.

- Power Systems: Monitors switchgear status and protection signals in substations.

- Process Control: Regulates temperature, pressure, and flow rates in chemical, oil, and gas industries.

- Traffic Systems: Controls traffic signals and vehicle detection sensors.

- Building Automation: Manages lighting, HVAC, and door access systems.

- Environmental Monitoring: Collects data from water quality and air quality sensors.

Compatibility

- Fully integrated with ABB IRC5 robotic controllers and 800xA DCS platforms.

- Supports third-party devices via Modbus, Profibus, and OPC UA protocols.

- Compatible with Windows XP, Windows 2000, and Windows XP Embedded for program development.

Reviews

There are no reviews yet.