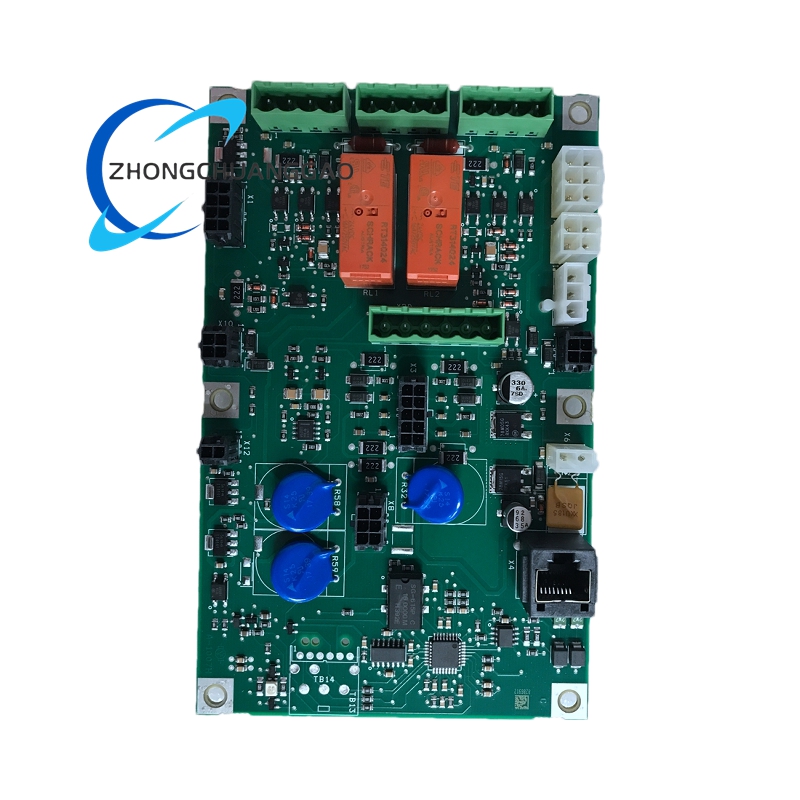

Product Short Description

Technical Specifications

- Dimensions: 31 mm × 19 mm × 8 mm

- Weight: 0.14 kg

- Processor: High-performance CPU for real-time motion control and algorithm execution.

- Communication Interfaces:

- Ethernet (10/100 Mbps)

- RS232/RS485 serial ports

- Modbus Plus, FIPWAY/FIPIO, and current-loop protocols.

- I/O Support:

- Digital input/output (DI/DO) modules.

- Analog input/output (AI/AO) modules.

- High-speed counter templates (up to 500 kHz).

- Power Supply: 24 VDC input with overvoltage protection.

- Operating Temperature: -20°C to +60°C (industrial-grade thermal tolerance).

- Humidity Resistance: Up to 95% non-condensing.

Description

Key Features

- High-Speed Processing: Equipped with a powerful processor for rapid response and low-latency control.

- Multi-Protocol Support: Seamlessly integrates with Ethernet, RS232/RS485, Modbus, and industrial fieldbus networks.

- Scalability: Modular design allows expansion of I/O channels and communication ports.

- Reliability: Advanced hardware design and rigorous testing ensure stable operation in vibrations, electromagnetic interference, and extreme temperatures.

- Diagnostic Tools: Built-in self-testing and fault detection for proactive maintenance.

- Programming Flexibility: Supports ladder logic, structured text, and flowchart programming via Windows-based platforms.

Functional Capabilities

- Motion Control: Executes complex trajectory planning and speed adjustments for robotic arms.

- Data Acquisition: Collects and processes real-time sensor data (e.g., voltage, current, position).

- Communication Management: Facilitates protocol conversion and data exchange between robots, PLCs, and HMI systems.

- System Monitoring: Tracks device status, performance metrics, and alarm triggers.

- Remote Access: Enables configuration and troubleshooting via secure network connections.

Application Scenarios

- Automotive Manufacturing: Controls welding robots, assembly lines, and paint shop automation.

- Electronics Production: Manages precision placement machines and testing equipment.

- Food and Beverage: Regulates packaging systems, conveyor belts, and quality inspection robots.

- Logistics and Warehousing: Automates material handling, sorting, and palletizing robots.

- Metal Fabrication: Operates cutting, bending, and welding robots in steel/aluminum processing.

- Pharmaceuticals: Ensures sterile environment control in drug manufacturing robots.

Compatibility

- Fully integrated with ABB IRC5 robotic control cabinets.

- Supports third-party devices via standard industrial protocols (e.g., PROFIBUS, DeviceNet).

- Compatible with ABB’s RobotStudio and PC SDK for program development.

Advantages

- Cost Efficiency: Reduces wiring complexity and maintenance costs through centralized control.

- Future-Proof Design: Firmware updates enable protocol expansions (e.g., adding OPC UA support).

- Global Support: Backed by ABB’s worldwide service network for technical assistance.

- Safety Compliance: Meets IEC 61131-3, ISO 10218, and SIL 2/3 standards for robotic safety.

Reviews

There are no reviews yet.