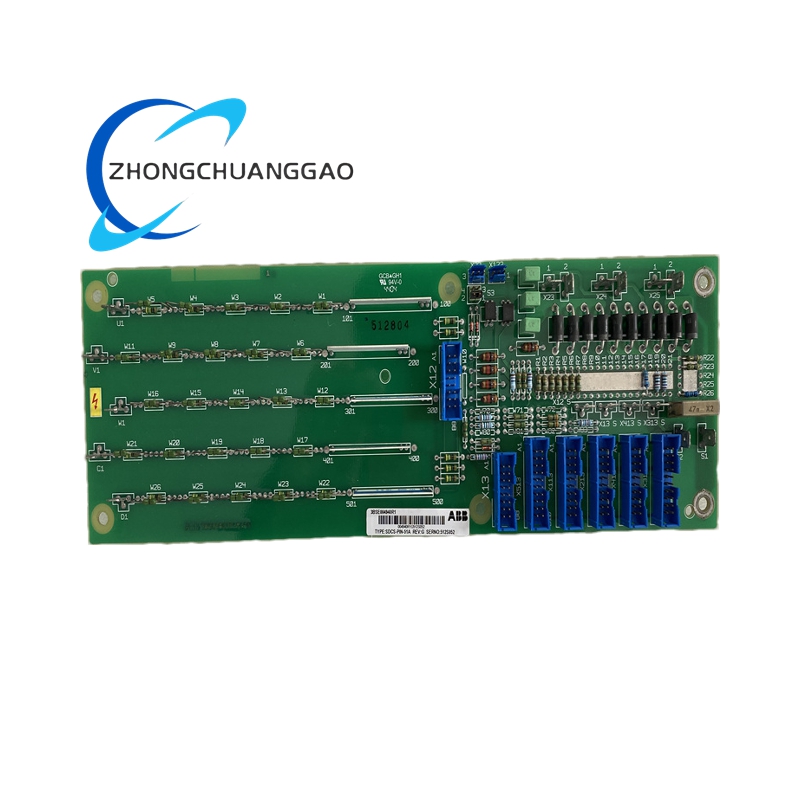

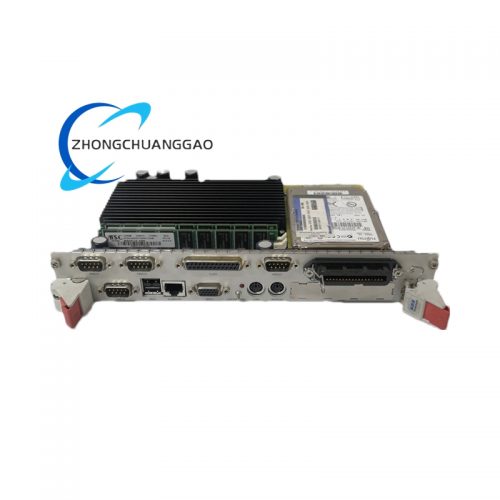

Product Short Description

Technical Specifications

- I/O Channels:

- 8 universal input channels (configurable for analog or digital signals).

- 4 digital output channels (sinking/sourcing, 24V DC).

- Analog Input Types:

- Voltage: 0-10V, ±10V.

- Current: 4-20mA, 0-20mA.

- Thermocouple: J, K, T, E, R, S, B types.

- RTD: PT100, PT500, PT1000.

- Digital Input/Output:

- Inputs: Dry contact or transistor-based signals.

- Outputs: 0.5A per channel (sinking/sourcing).

Description

- Resolution: 16-bit for analog inputs, ensuring high-precision measurements.

- Accuracy: ±0.1% for analog signals, ±0.05% for RTD/thermocouple inputs.

- Response Time: <5ms for analog signals, <1ms for digital signals.

- Isolation: Channel-to-channel and channel-to-bus isolation for enhanced safety.

- Operating Temperature: -20°C to +70°C, suitable for harsh industrial environments.

- Protection Level: IP65-rated, providing dust-tight and waterproof protection.

- Power Supply: DC 24V ±10%, with low power consumption.

- Mechanical Design: Compact and rugged, designed for DIN rail mounting in control cabinets.

- Diagnostic LEDs: Per-channel status indicators for easy monitoring.

Functional Characteristics

- Universal Signal Support: Handles analog, digital, thermocouple, and RTD signals in a single module.

- High Precision: 16-bit resolution and low measurement error ensure accurate process control.

- Flexible Configuration: Each input channel can be independently configured for voltage, current, or temperature signals.

- Fast Signal Processing: Sub-millisecond response for digital outputs and low-latency analog conversion.

- Robust Isolation: Prevents electrical interference and ensures safe operation in noisy environments.

- Comprehensive Diagnostics: Onboard LEDs and status feedback simplify system monitoring and troubleshooting.

- Easy Integration: Compatible with ABB’s SDCS control systems and standard industrial communication protocols.

Application Scenarios

- Process Control: Monitors and regulates temperature, pressure, flow, and level in chemical, petrochemical, and pharmaceutical industries.

- Factory Automation: Controls motors, valves, and actuators in manufacturing lines, robotic systems, and packaging machinery.

- Power Generation: Manages generator parameters, electrical distribution, and auxiliary systems in power plants.

- Water Treatment: Optimizes pump control, water quality monitoring, and valve positioning in municipal and industrial facilities.

- Building Automation: Integrates HVAC, lighting, and security systems in commercial and residential buildings.

- Material Handling: Enhances conveyor systems, sorting equipment, and warehouse automation in logistics operations.

Industry Applications

- Chemical and Petrochemical Processing

- Pharmaceutical Manufacturing

- Oil and Gas Refining

- Power Generation and Distribution

- Water and Wastewater Treatment

- Automotive Assembly Lines

- Food and Beverage Production

- Metals and Mining Operations

- Textile and Pulp & Paper Industries

- Building Management Systems (BMS)

Reviews

There are no reviews yet.