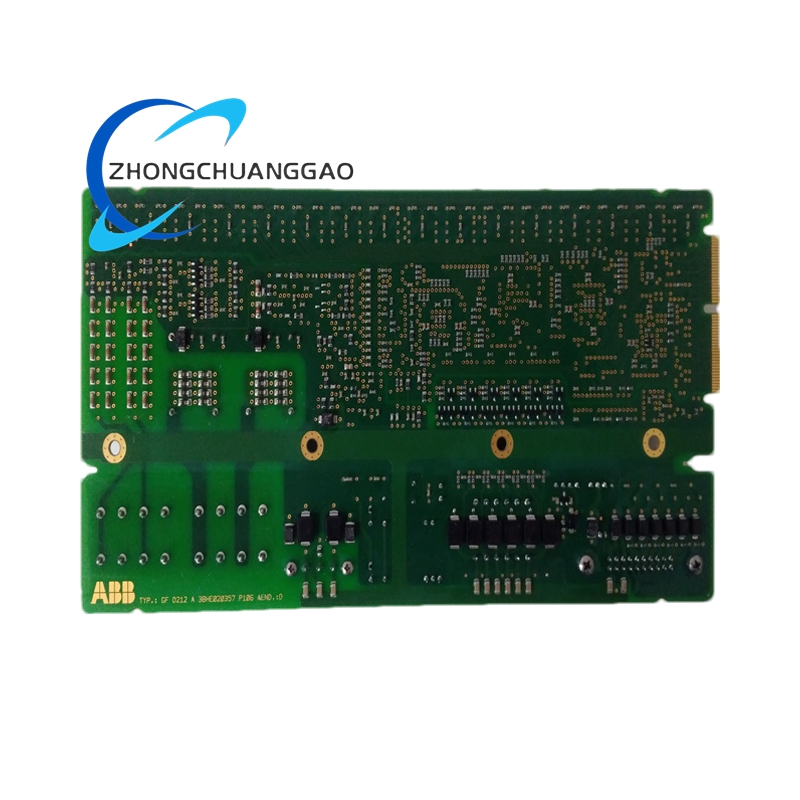

Product Short Description

Technical Specifications

- Power Supply: 24 VDC (typical operating voltage); 18–30 VDC (voltage range)

- Power Consumption: ≤ 15 W (maximum operating power)

- Operating Temperature Range: -40 °C to +70 °C

- Storage Temperature Range: -40 °C to +85 °C

- Humidity Resistance: 0–95% relative humidity (non-condensing)

- Communication Interfaces: Supports Modbus RTU, PROFINET, and Ethernet/IP (for seamless connection with upper-level control systems)

- Input/Output (I/O) Signals:

- Digital input: 8 channels (24 VDC, sink/source configurable)

- Digital output: 4 channels (relay output, 250 VAC/30 VDC, 5 A)

Description

- Dimensions: 140 mm × 80 mm × 60 mm (length × width × height; DIN rail-mountable)

- Certifications: Complies with IEC 61000-6-2 (industrial immunity) and IEC 60529 (IP20 protection rating)

Functional Features

- Stable Signal Processing: Filters and amplifies weak industrial signals to eliminate electromagnetic interference (EMI), ensuring accurate data collection and transmission.

- Dual-Part Compatibility: Pre-calibrated for use with 3BHE020356R0101 and 3BHE020357P201, reducing on-site configuration time and ensuring plug-and-play integration.

- Fault Self-Diagnosis: Monitors internal circuits and external signal connections in real time; triggers visual/electrical alarms for anomalies (e.g., power failure, signal loss) to facilitate quick troubleshooting.

- DIN Rail Mounting: Adopts standard DIN rail design for easy installation in control cabinets, saving space and simplifying system layout.

- Wide Environmental Adaptability: Withstands extreme temperatures, high humidity, and industrial electromagnetic interference, maintaining performance in heavy-industry settings.

- Data Logging: Stores key operational data (e.g., input/output status, voltage fluctuations) for up to 30 days, supporting post-event analysis and preventive maintenance.

Application Scenarios

- Power Generation Industry: Integrated into thermal power or hydropower plant control systems to monitor and control auxiliary equipment (e.g., pump stations, ventilation fans).

- Petrochemical Industry: Used in refinery or chemical plant process control loops to transmit valve position signals and pump operation status.

- Metallurgical Industry: Supports temperature and pressure signal processing for steelmaking or aluminum smelting equipment, ensuring stable production processes.

- Manufacturing Automation: Deployed in automated production lines (e.g., automotive assembly, electronic component manufacturing) to coordinate sensor and actuator operations.

- Water Treatment Plants: Controls water pump speed and valve switching, and transmits water quality sensor data to central control systems.

- Marine and Offshore Applications: Adapted for offshore oil platforms or shipboard automation systems, with anti-vibration and corrosion-resistant properties to meet marine environmental requirements.

Be the first to review “ABB GFD212A 3BHE020356R0101 3BHE020357P201” Cancel reply

Reviews

There are no reviews yet.