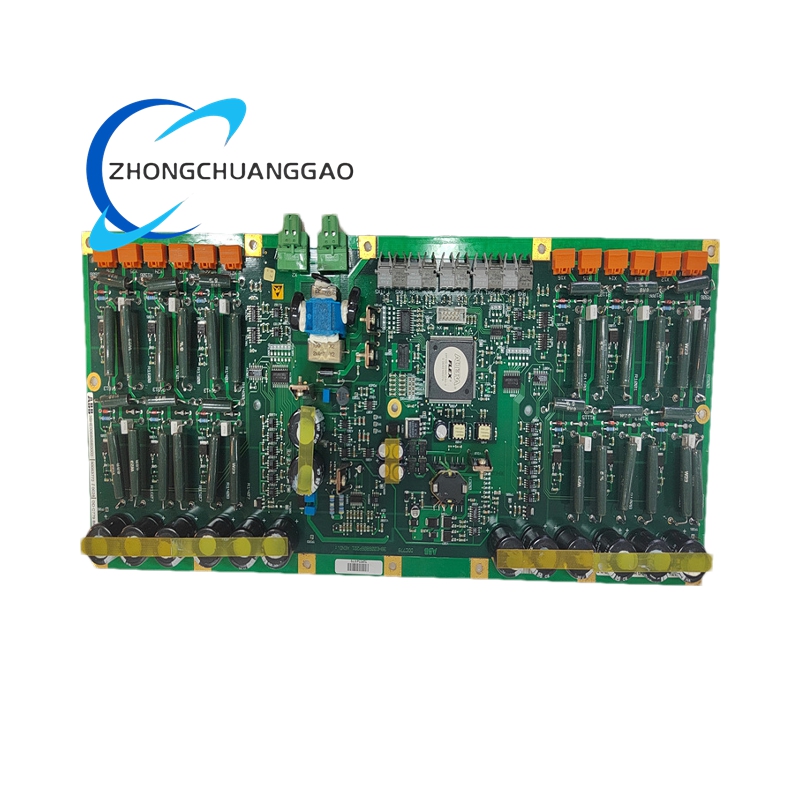

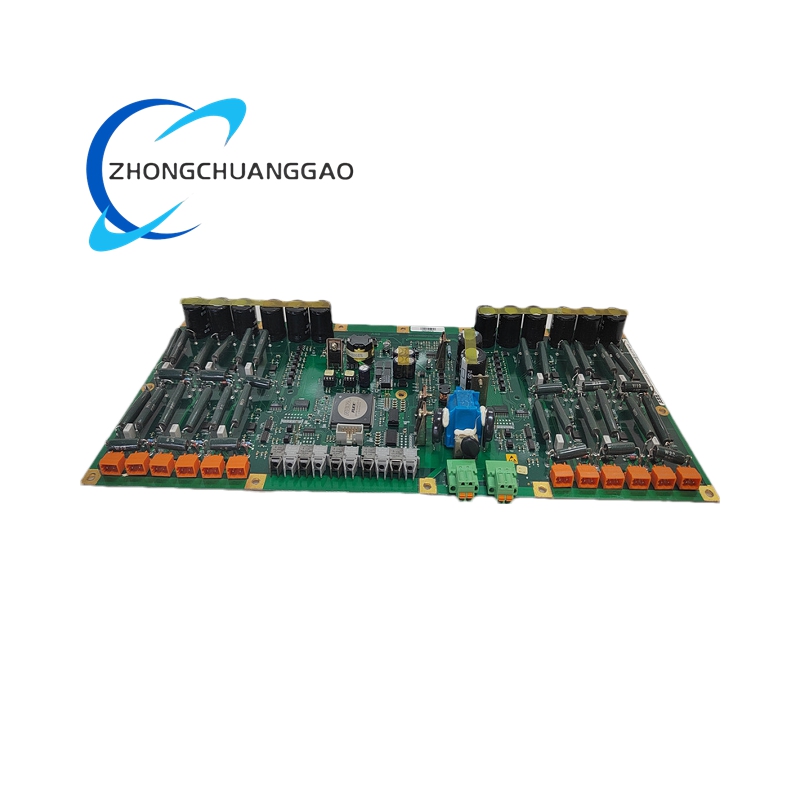

Product Short Description

Technical Specifications

- Control Signals:

- Digital Input (DI): 8 channels, 24 V DC, sinking/sourcing type, response time ≤ 1 ms.

- Digital Output (DO): 6 channels, 24 V DC/230 V AC, relay output (contact rating: 2 A @ 250 V AC, 3 A @ 30 V DC).

- Operating Voltage: 24 V DC ±10%, power consumption ≤ 15 W (typical).

- Operating Temperature: -25°C to +70°C, suitable for harsh industrial on-site temperature conditions.

- Storage Temperature: -40°C to +85°C, ensuring stability during transportation and long-term storage.

- Isolation: Galvanic isolation between input/output channels, power supply, and communication ports; isolation voltage ≥ 2500 V AC (1 minute), isolation resistance ≥ 100 MΩ (500 V DC).

- Communication Interface: 1 x RS485 (Modbus RTU protocol), baud rate 9600–115200 bps, supporting half-duplex communication for data exchange with DCS/PLC systems.

Description

- Mounting Type: DIN rail mounting (compatible with standard 35 mm DIN rails), installation depth ≤ 120 mm.

- Dimensions: 140 mm (width) × 90 mm (height) × 60 mm (depth), optimizing space in control cabinets.

- Certifications: Complies with IEC 61131-2 (industrial control equipment), IEC 61000-6-2 (EMC immunity), and CE marking standards.

Functional Features

- Integrated Direct Control: Supports closed-loop control logic (e.g., PID control for temperature, pressure, and flow) and open-loop control (e.g., on/off control for pumps and valves), eliminating the need for external control units and simplifying system architecture.

- High-Speed Signal Processing: Equipped with a 32-bit microprocessor, enabling control cycle times as low as 10 ms to ensure rapid response to changes in field process parameters.

- Fault Diagnostics & Indication: Real-time monitoring of module power, input/output channel status, and communication links. Faults (e.g., channel short circuits, power abnormalities, communication failures) trigger LED indicators (red for faults, green for normal operation) and send fault codes to upper-level systems for quick troubleshooting.

- Configuration Flexibility: Supports parameter configuration via ABB’s dedicated configuration software (e.g., Control Builder Plus) or Modbus communication. Users can customize control algorithms, input/output thresholds, and communication parameters to adapt to different application requirements.

- EMI/RFI Resistance: Adopts reinforced electromagnetic compatibility (EMC) design, meeting IEC 61000-6-3 standards for EMC emissions. It resists radio frequency interference (RFI) and electromagnetic interference (EMI) from industrial equipment, ensuring stable operation in complex electrical environments.

- Redundancy Support (Optional): Some versions support dual-module redundancy configuration, automatically switching to the standby module if the main module fails, ensuring uninterrupted control and improving system reliability.

Application Scenarios

- Power Generation: Used in thermal power plants, hydropower plants, and wind farms. It controls auxiliary equipment such as feedwater pumps, cooling fans, and fuel valves, regulating parameters like water level, pressure, and temperature to support stable operation of turbines and generators.

- Oil & Gas Industry: Deployed in oil refineries, natural gas processing plants, and pipeline systems. It executes control logic for process units (e.g., distillation columns, reactors) and safety equipment (e.g., emergency shut-off valves), ensuring compliance with process safety standards and stable production.

- Chemical Manufacturing: Applied in chemical plants for controlling mixing tanks, heat exchangers, and dosing pumps. It maintains precise control of chemical reaction parameters (temperature, pressure, concentration) to improve product quality and reduce waste.

- Water & Wastewater Treatment: Used in water treatment plants for controlling filtration systems, chemical dosing units, and pump stations. It regulates water flow, pH value, and chlorine concentration to meet water quality standards.

- Industrial HVAC: Integrated into heating, ventilation, and air conditioning systems of large factories or commercial buildings. It controls air handlers, chillers, and dampers to maintain stable indoor temperature and humidity, optimizing energy efficiency.

Be the first to review “ABB DDC779BE02 3BHE006805R0002” Cancel reply

Reviews

There are no reviews yet.