Product Short Description

Technical Specifications

- Signal Input/Output (I/O) Types: Supports analog signals (4 – 20 mA DC current signals, 0 – 10 V DC voltage signals) and digital signals (24 V DC discrete signals for status detection and control commands).

- Operating Voltage: 24 V DC (typical), with a voltage tolerance range of ±10% to adapt to fluctuations in industrial power supplies.

- Operating Temperature: -20°C to +60°C, suitable for harsh industrial on – site temperature environments.

- Storage Temperature: -40°C to +85°C, ensuring stability during transportation and long – term storage.

- Isolation Protection: Provides galvanic isolation between input/output channels and the power supply (isolation voltage ≥ 2500 V AC, isolation resistance ≥ 100 MΩ at 500 V DC), preventing signal interference and equipment damage caused by ground loops or voltage surges.

Description

- Mounting Type: DIN rail mounting (compatible with standard 35 mm DIN rails), facilitating quick installation and integration into control cabinets.

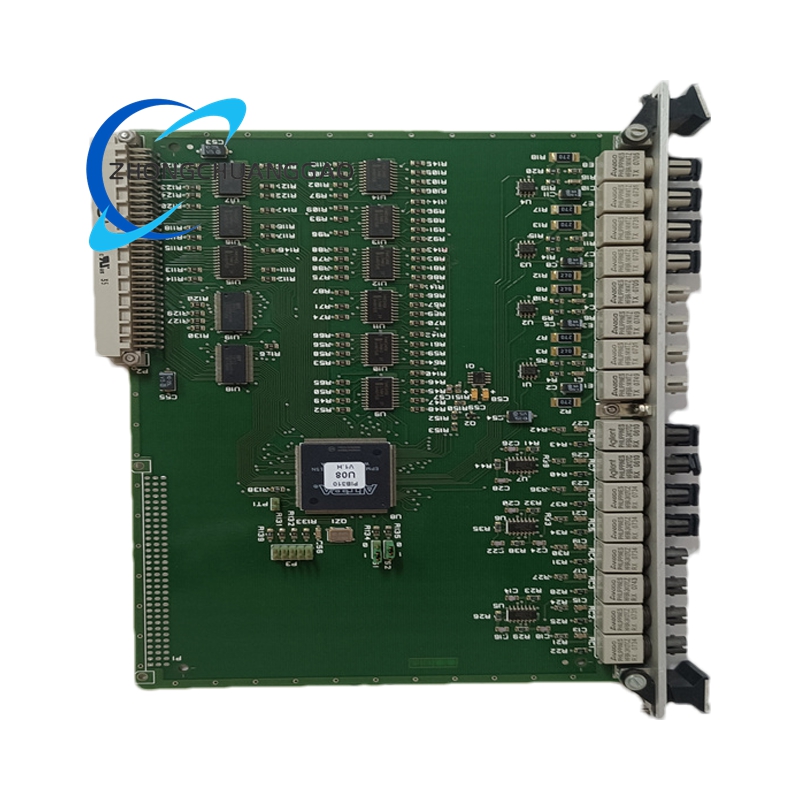

- Dimensions: Standard industrial board size (typically 100 mm × 150 mm × 25 mm, thickness included), optimizing space utilization in control cabinets.

- Communication Compatibility: Works with ALSTOM’s proprietary control system protocols (e.g., ALSPA series) to ensure smooth data exchange with upper – level controllers.

Functional Features

- Multi – Signal Compatibility: Integrates analog and digital I/O functions in a single board, eliminating the need for multiple independent interface modules and reducing system complexity and hardware costs.

- Signal Conditioning: Built – in signal filtering and amplification circuits. It filters out high – frequency noise in field signals (with a filtering bandwidth of 50 Hz/60 Hz notch filter) and amplifies weak signals (gain adjustable for analog inputs) to ensure the accuracy of acquired signals.

- Diagnostic Capabilities: Equipped with real – time self – diagnosis and fault indication functions. It monitors the status of power supply, I/O channels, and signal integrity in real time; when faults (such as open circuits in input signals, short circuits in output channels, or power supply abnormalities) occur, it triggers LED indicator lights (red for faults, green for normal operation) to facilitate on – site maintenance personnel to quickly locate and resolve issues.

- High Stability and Reliability: Adopts industrial – grade components (with a mean time between failures (MTBF) ≥ 100,000 hours) and a reinforced board design, resisting vibration (10 – 500 Hz, 1 g acceleration) and electromagnetic interference (EMI) in industrial environments, ensuring continuous operation of the board.

- Hot – Swappable Support (Optional): Some versions support hot swapping (under specified operating conditions), allowing replacement or maintenance of the board without shutting down the entire control system, minimizing production downtime.

Application Scenarios

- Power Generation Industry: Used in thermal power plants, hydropower plants, and nuclear power plants (auxiliary systems). It connects field equipment such as temperature sensors (for boiler water temperature), pressure transducers (for steam pressure), and control valves (for feedwater control) to ALSTOM’s power plant control systems (e.g., ALSPA P320 DCS), supporting parameter monitoring and control of boiler, turbine, and auxiliary systems.

- Metallurgical Industry: Applied in steel mills and aluminum smelters. It interfaces with field devices like level sensors (for molten steel ladle level), flow meters (for cooling water flow), and frequency converters (for rolling mill motor control) to transmit process data to the metallurgical process control system, ensuring stable operation of smelting, rolling, and casting processes.

- Oil and Gas Industry: Deployed in oil refineries, natural gas processing plants, and pipeline transportation systems. It acquires signals from pressure sensors (for pipeline pressure), flow transducers (for oil/gas flow), and temperature probes (for reactor temperature), and sends control commands to actuators (such as emergency shut – off valves) to support safe and efficient operation of oil and gas processing and transportation processes.

- Industrial Automation (General Manufacturing): Used in large – scale manufacturing plants (such as chemical plants, paper mills, and cement plants). It serves as an interface between field process equipment and the factory’s DCS or PLC systems, realizing monitoring and control of key process parameters (temperature, pressure, flow, level) to improve production efficiency and product quality.

Be the first to review “ALSTOM PIB310 3BHB0190” Cancel reply

Reviews

There are no reviews yet.