Product Short Description

- Technical Specifications

- Communication Interface: It is connected to the Foxboro DCS control network through a standard fiber – optic or copper 100 Mbps Ethernet cable. The standard FCP280 backplane has each field – bus port supporting a 2 Mbps or 268 Kbps HDLC field – bus dedicated port. It also supports communication protocols such as HART and Modbus.

- Power Supply: The specific power – supply information is not clearly stated, but generally, it is suitable for the power supply environment of industrial control systems, usually DC power supply.

- Operating Temperature: It can work in G3 – level harsh environments, and the operating temperature range is generally – 20 °C to 70 °C (estimated according to similar products, for reference only).

- Dimensions and Weight: There is no publicly available official data on dimensions and weight. However, it is encapsulated in a die – cast aluminum enclosure, and the structure is relatively compact, suitable for field installation.

- I/O Capacity: It can support up to 128 compact or standard 200 – series FBMs, 128 100 – series FBMs, or a combination of 100 – series and 200 – series FBMs (with a maximum of 64 100 – series FBMs allowed on each PIO bus/backplane port).

Description

- Function Features

- Powerful Control Functions: It can perform regulatory, logic, timing, and sequential control, as well as data acquisition, alarm detection, and notification. Using time – tested algorithms, these algorithms are included in function control blocks, and field process engineers can configure them to implement the required control strategies.

- Fault – Tolerant Design: The fault – tolerant version consists of two parallel – running modules, with two Ethernet connections to the control network. When a hardware failure occurs in one module, the other non – affected module can take over control to ensure continuous operation of the controller.

- Online Image Upgrade: It supports online image upgrade (OLUG). There is also an enhanced online image upgrade (EOLUG) for fault – tolerant FCP280, which can be upgraded during the process operation without significantly affecting the local control process.

- Overload Protection: It provides CP overload protection, which can notify the operator when the performance of FCP280 reaches its limit.

- Data Integration: It can realize plant – wide data integration, connect to various field devices, and collect and process data.

- Self – hosting Mode: It supports the self – hosting mode. Even if the host workstation is offline, FCP280 can start with a valid control database, but the control function cannot be edited.

- Time Synchronization: It supports optional external time synchronization from GPS satellites to ensure the accuracy of system time.

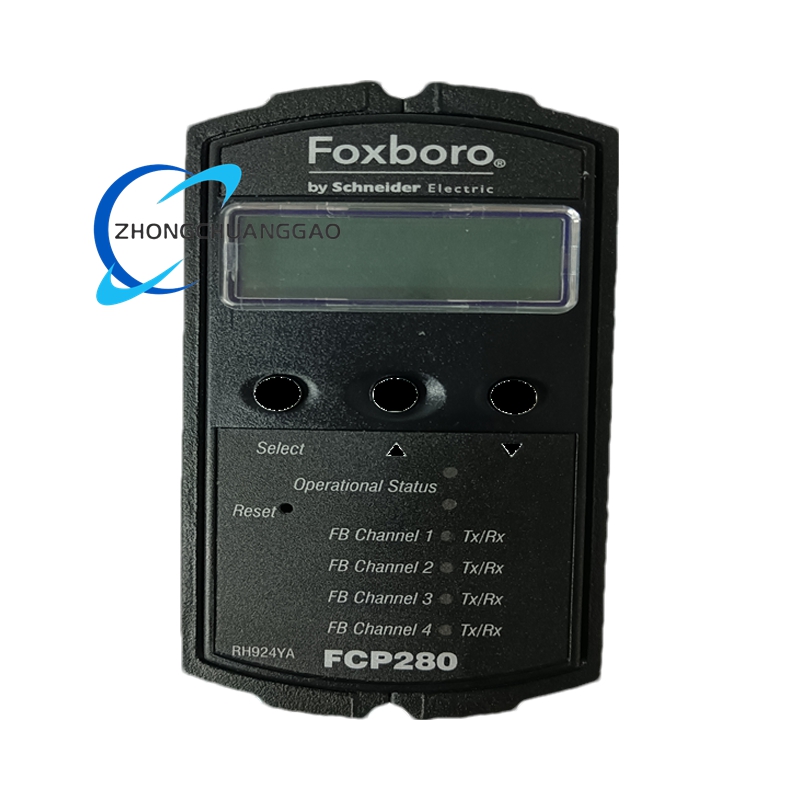

- LCD Display: It is equipped with a liquid – crystal display (LCD) to display alphabetic errors and real – time roles and status.

- Application Scenarios

- Petrochemical Industry: It is used for process control in refineries and chemical plants, such as controlling the temperature, pressure, and flow of reactors and distillation columns, and monitoring the composition of chemical substances.

- Power Industry: It is used to monitor and control equipment such as boilers, steam turbines, and generators in power plants, ensuring the stable operation of the power – generation system and the quality of power supply.

- Metallurgical Industry: It is applied to the production process control of steel plants and aluminum plants, such as controlling the temperature and speed of furnaces, and the feeding and discharging of materials.

- Water Treatment Industry: It is used to monitor water quality parameters, control the start – stop of water pumps, the opening and closing of valves, and realize the automation of the water treatment process.

- Food and Beverage Industry: It is used to control the production process of food and beverage enterprises, such as the temperature control of food processing, the speed control of conveyor belts, and the mixing proportion control of raw materials.

- Life Science and Pharmaceutical Industry: It is used to realize the control of complex chemical reaction processes, ensure the accuracy and stability of pharmaceutical production processes, and meet the requirements of GMP.

- Data Center: It provides reliable power system monitoring and control, monitors the power supply status of the data center, controls the on – off of power distribution equipment, and ensures the stable operation of the data center.

Be the first to review “FOXBORO FCP280 Field Control Processor” Cancel reply

Reviews

There are no reviews yet.