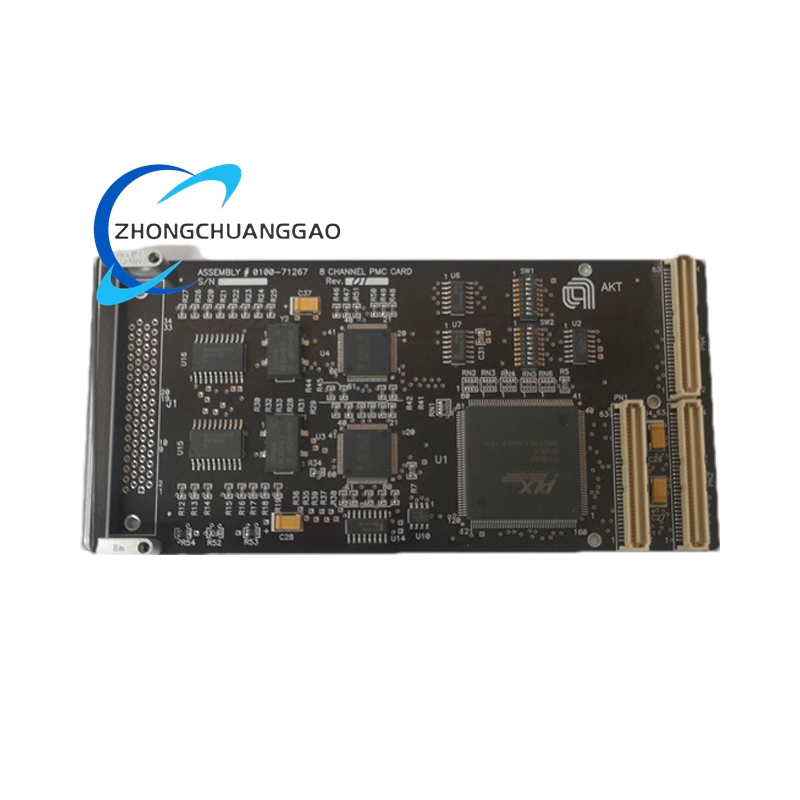

Product Short Description

- Physical & Electrical:

- Dimensions: 10 cm × 10 cm × 5 cm (L × W × H) .

- Weight: 1 kg .

- Material: Stainless steel housing .

- Power Supply: 110–240V AC input; 24V DC output .

- Power Consumption: <10W .

- Operating Temperature: -20°C to +70°C (industrial-grade range) .

- Storage Temperature: -40°C to +85°C .

- Protection Rating: IP54 (dust/moisture-resistant) .

Description

- Processing & Memory:

- CPU: Embedded 32-bit RISC processor .

- Memory: 256 KB RAM + 512 KB Flash .

- I/O Channels: 8 configurable digital/analog channels (supports pulse counting up to 1 MHz) .

- Communication & Interfaces:

- Wired Protocols: RS-232/422/485 .

- Wireless: Embedded 802.11b/g/n Wi-Fi .

- Ethernet: Integrated web server for remote configuration .

Functional Features

- High-Precision Control:

- Signal Processing: Counts and processes pulse/level signals from sensors (e.g., temperature, pressure, flow) with ±0.1% accuracy .

- Multi-Protocol Support: Handles Modbus, PROFIBUS, and custom OEM command sets .

- Robust Industrial Design:

- Hot-Swap Capability: Modular design for maintenance without downtime .

- Self-Diagnostics: Front-panel LEDs for real-time fault alerts (overload, short circuit) .

- Environmental Resilience: Conformal coating for chemical/humidity resistance .

- Advanced Connectivity:

- CLI & Web Interface: Full configuration via embedded command line or browser-based GUI .

- Data Logging: Stores 10,000+ event timestamps for production analytics .

- Safety & Compliance:

- Protection Mechanisms: Overcurrent/overvoltage shutdown and arc flash reduction .

- Certifications: CE, RoHS, SIL 2 (functional safety) .

Application Scenarios

- Semiconductor Manufacturing:

- Wafer Processing: Controls etch/deposition tools in fabs (e.g., Applied Materials Endura® systems) .

- Yield Monitoring: Tracks production counts and equipment fault rates .

- Industrial Automation:

- Robotic Lines: Synchronizes KUKA/PROFINET systems in automotive assembly .

- Smart Warehousing: Manages inventory via sensor-based item counting .

- Energy & Infrastructure:

- Grid Protection: Detects anomalies in substations and triggers circuit breakers .

- Water Treatment: Monitors pump station flow rates via Modbus RTU .

- Pharmaceuticals & Electronics:

- Precision Filling: Ensures vial/capsule counts in drug packaging .

- OLED Panel Production: Regulates deposition processes in display fabs .

Compatibility & Integration

- Hardware Ecosystems:

- Controllers: Honeywell Experion PKS, ABB AC 800M, Siemens S7-1500 .

- Field Devices: Interfaces with Allen Bradley/Rockwell I/O modules .

- Software Tools:

- Engineering Suites: Applied Materials FabGuard for real-time diagnostics .

- Third-Party Platforms: Compatible with Ignition SCADA for data historization .

Installation & Maintenance

- Deployment Guidelines:

- Mounting: DIN rail (EN 60715) with ≥50 mm ventilation clearance .

- Cabling: Shielded twisted pairs for EMI immunity; max 30m to controllers .

- Preventive Protocols:

- Biannual: Connector cleaning and firmware updates via web CLI .

- Annual: I/O calibration using Honeywell Service Toolkit .

- Troubleshooting:

- Signal Drift: Recalibrate offset/gain per SEMI E125 specs .

- Wi-Fi Dropout: Verify 802.11 channel congestion .

Certifications & Support

- Warranty: 12 months (extendable to 36 months) .

- Global Service: AMAT-certified engineers; 48-hour critical response .

- Compliance: ATEX Zone 2, IEC 61131-2, SEMI S2/S8 .

Reviews

There are no reviews yet.